Micro-blanking automation device of pulsed laser driven flying sheet loading plate and method thereof

An automated device and pulsed laser technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems affecting processing accuracy, errors, and hidden dangers of laser light path safety, and achieve the effect of avoiding human errors and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

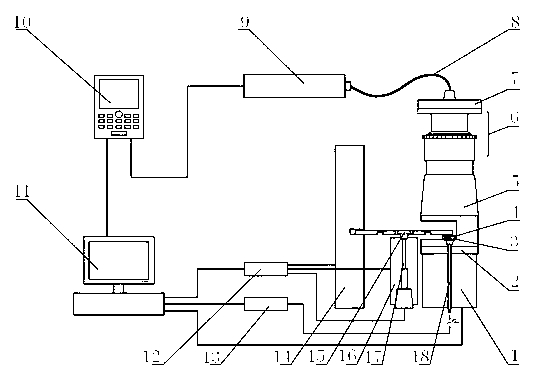

[0036] The structure of the micro-punching automation device of the present invention driven by the pulsed laser to load the thin plate is as follows figure 1 As shown, it includes three parts: laser generating system, automatic forming system and control system.

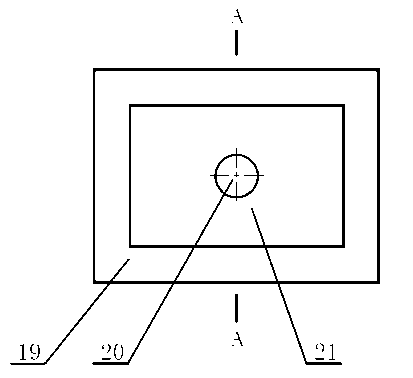

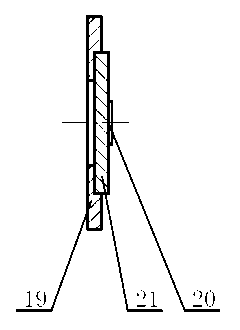

[0037] The laser generating system is composed of a laser controller 10, a laser transmitter 9 and an optical fiber 8; the automatic forming system is composed of an end cover 7, a focusing lens barrel 6, a body 5, a micro-punching workbench 4, a three-coordinate moving chuck 3, and a base 2. The variable magnetic field device 1, the turntable multi-position device 17, the constrained layer-flying sheet integrated sheet 15, the constrained layer-flying sheet integrated sheet storage bin 14, and the recovery device 16; the control system consists of a computer 11, a laser controller 10, The three-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com