High-precision shaft part machining method based on multiple times of detection and compensation

A shaft part, multiple detection technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the effect of error analysis, compensation and correction, can not achieve sub-micron accuracy, does not consider high surface roughness, etc. problems, to achieve the effect of achieving measurement, avoiding offline inspection and re-installation of workpieces, and improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

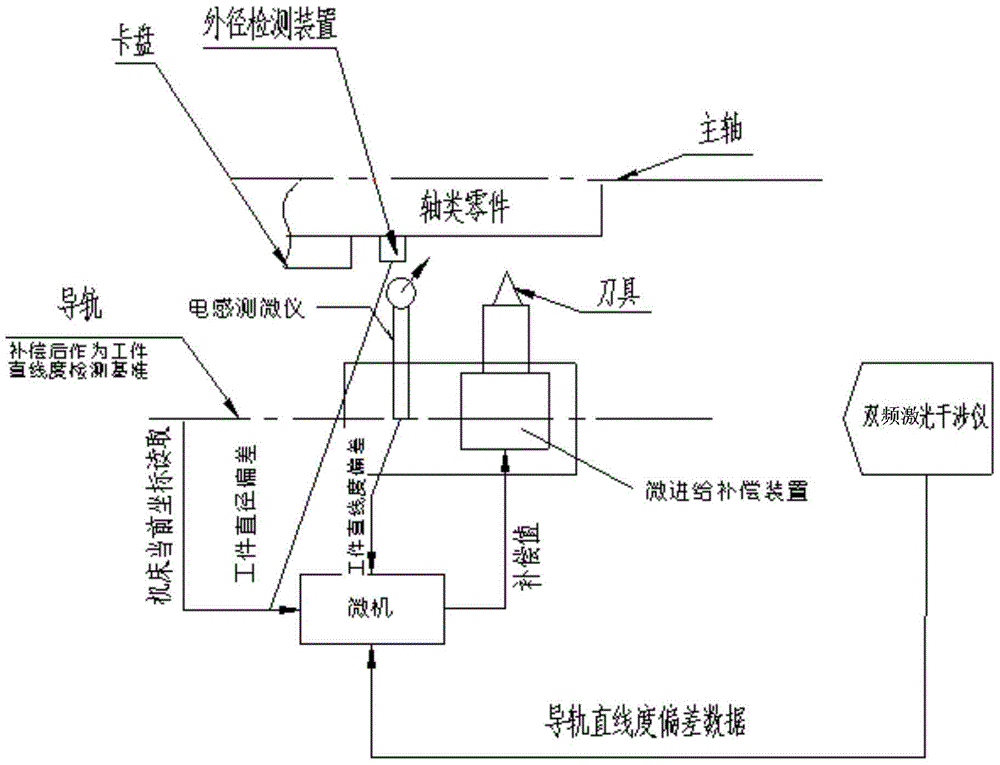

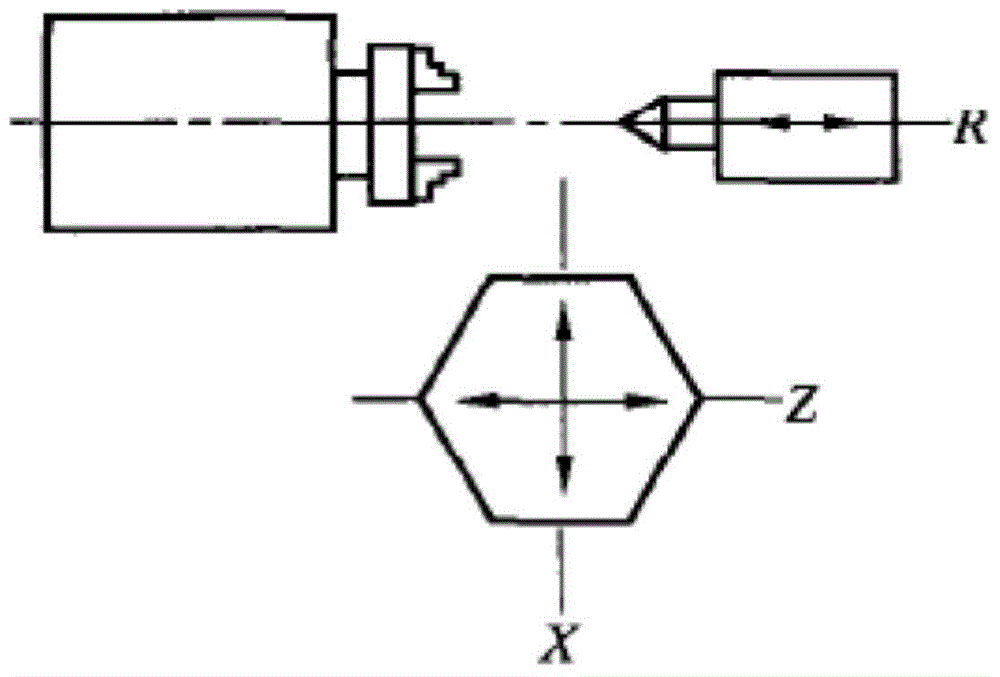

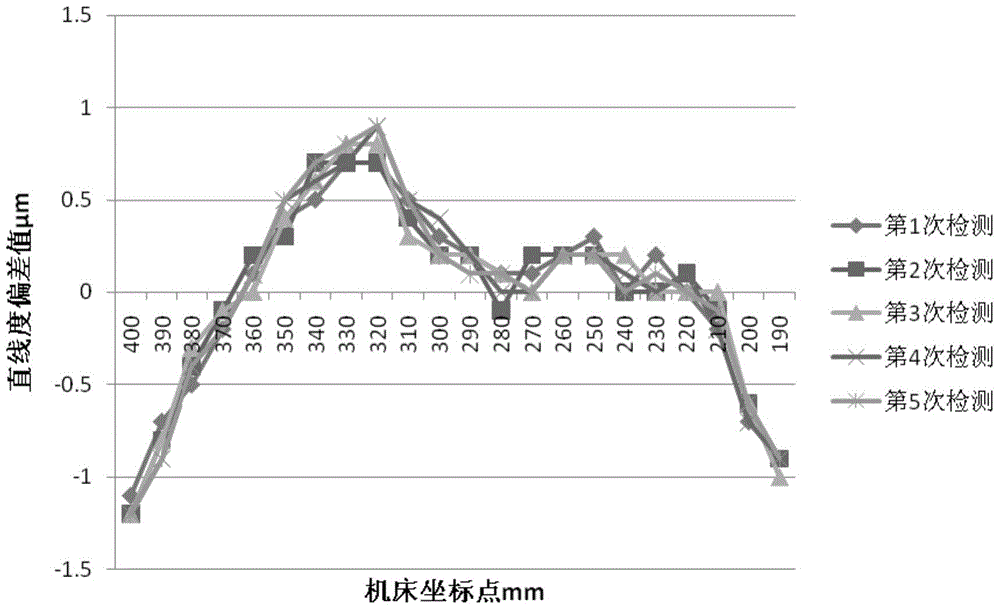

[0046] Such as figure 1 with figure 2 The processing system shown includes a microcomputer, a controller, a micro-feed compensation device, a walking board, a lathe guide rail, an inductance micrometer, a dual-frequency laser interferometer, an outer diameter detection device and shaft parts, and the Z axis is parallel to the processing guide rail , X-axis and Z-axis are perpendicular to the horizontal direction, the CNC lathe is 180CCN CNC lathe, the positioning error of the machine tool is 2μm, and the Z-axis of the CNC lathe is commonly used for strokes of 400mm to 190mm for shaft processing.

[0047] Step 1. Install the beam splitter of the dual-frequency laser interferometer on the extended end of the micro-feed compensation device, and fix the mirror on the machine tool. The CNC lathe moves along the Z guide rail at a constant speed from the coordinate 400mm to 190mm, and stops for 10 minutes at intervals of 10mm. Seconds, after the machine tool and the measuring syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com