Pipe blind hole-based drilling and milling machine tool capable of realizing multi-station machining

A multi-station, processing drilling technology, which is applied in the direction of metal processing machinery parts, milling machines, milling machine equipment, etc., can solve the problems of large positioning error, high labor intensity, complicated operation, etc., and achieve reduced participation, low labor intensity, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

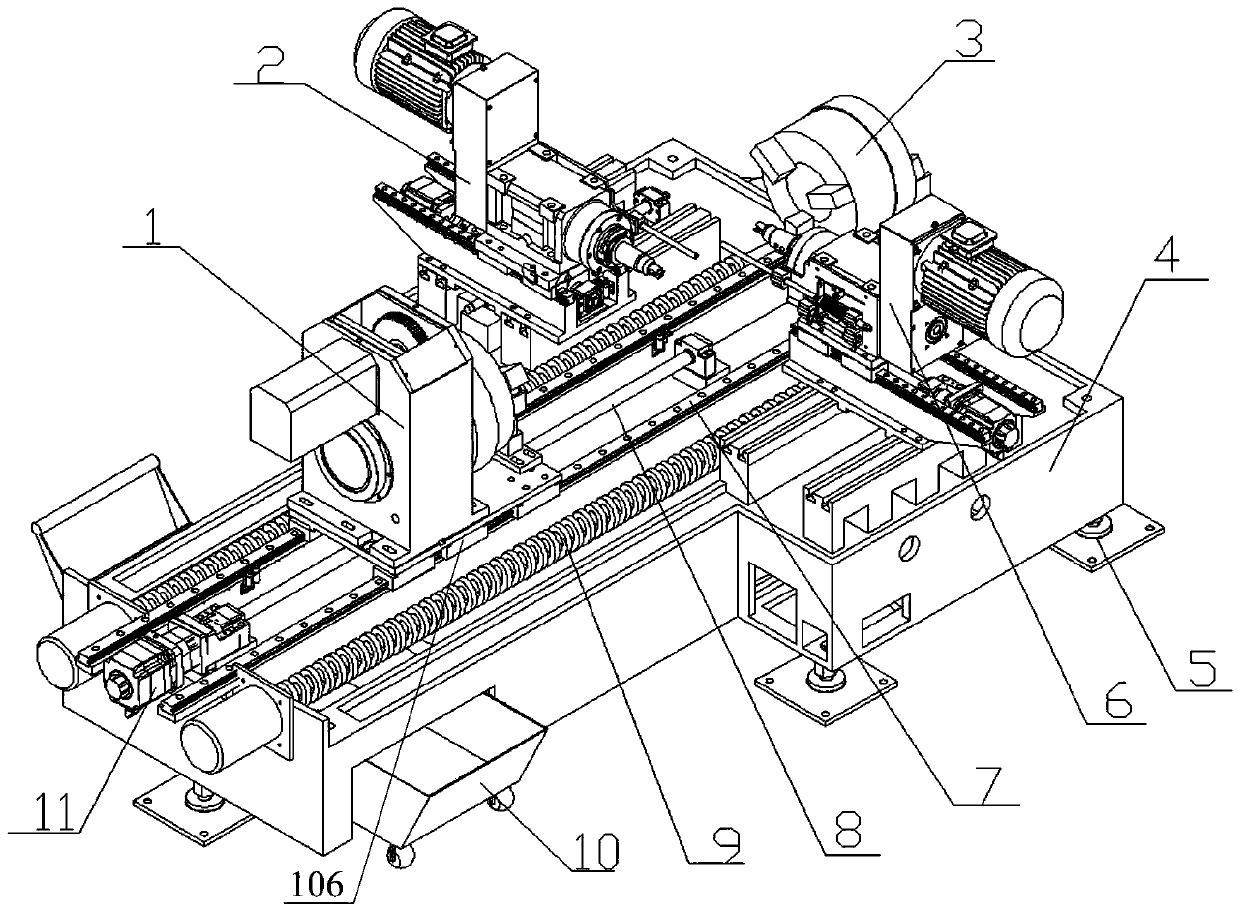

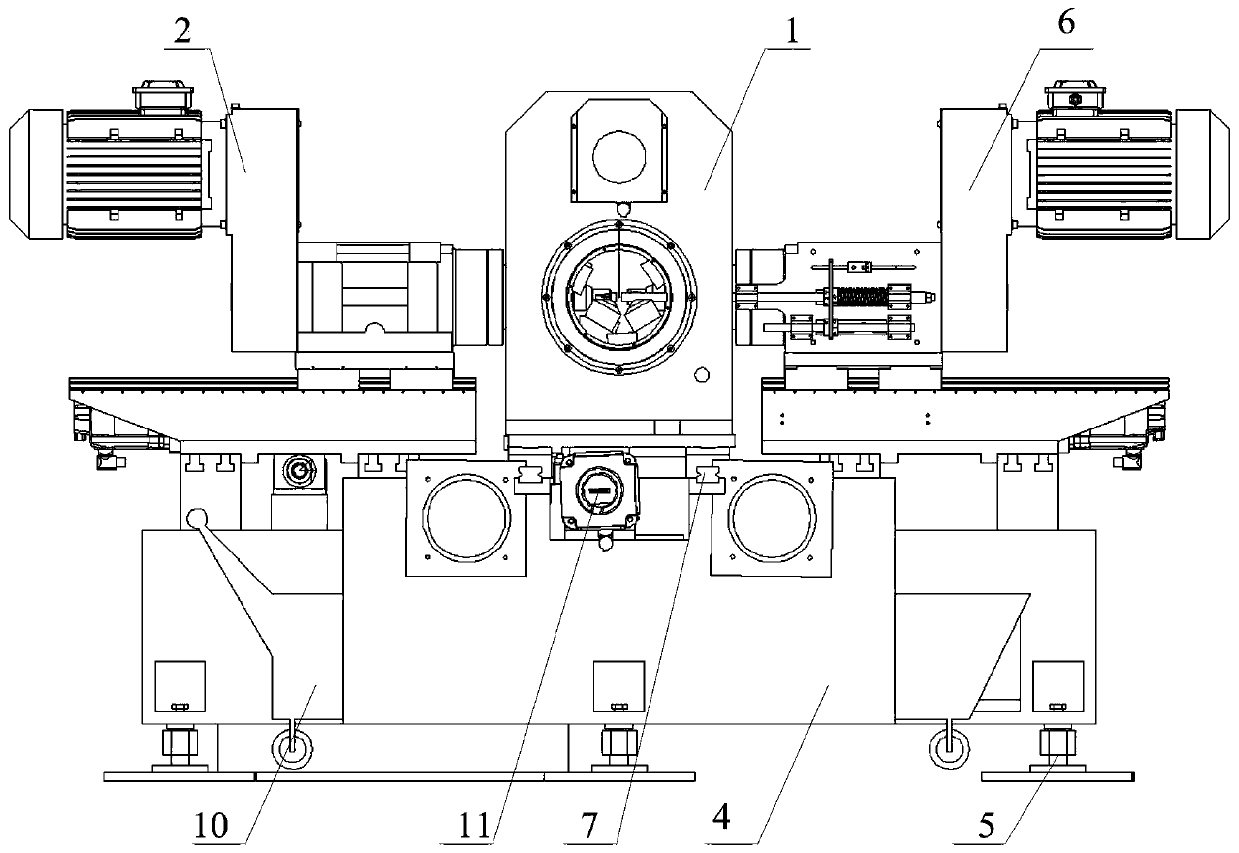

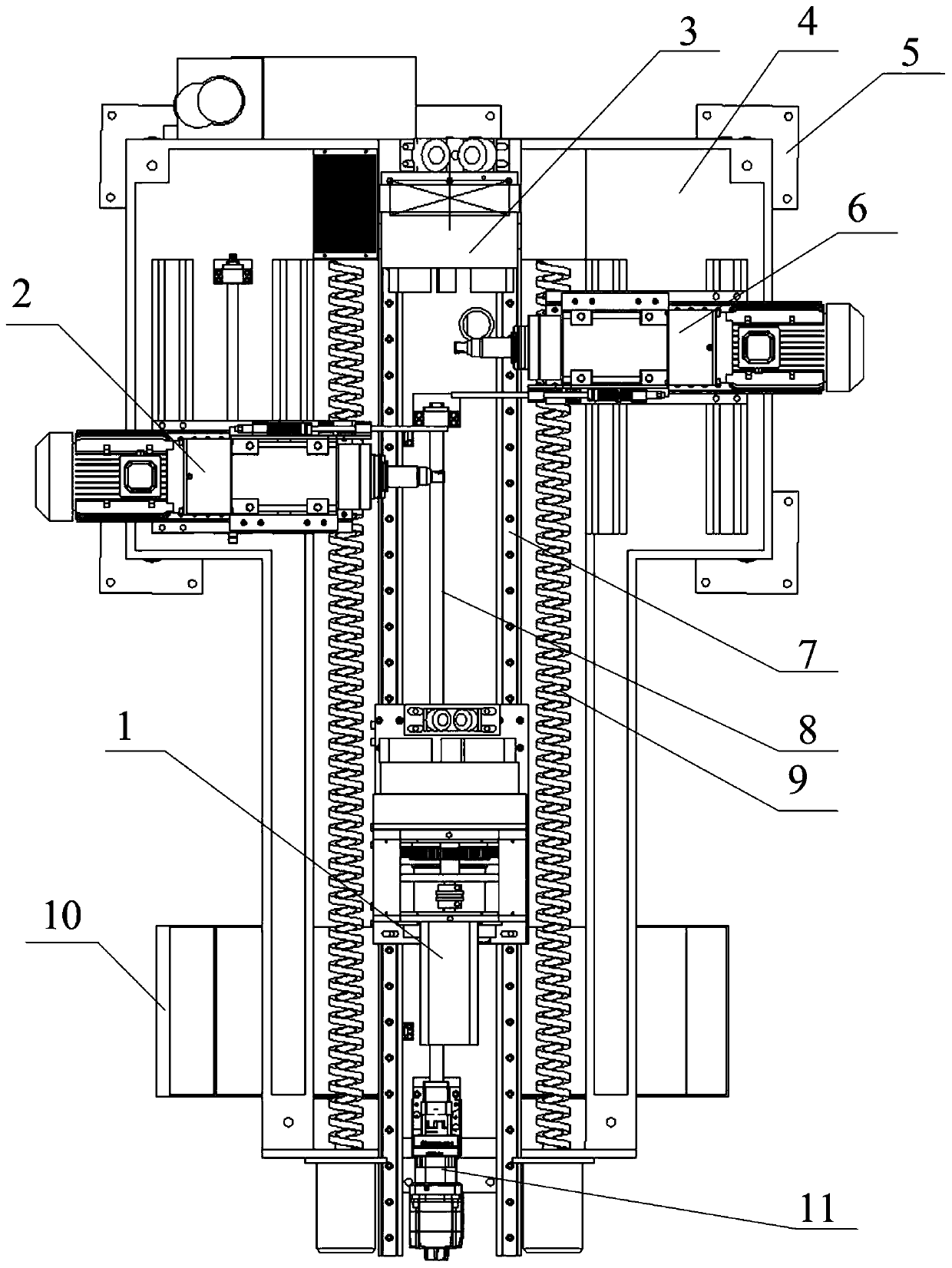

[0078] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0079] Such as Figure 1 to Figure 4 As shown, the multi-station machining drilling and milling machine tool based on pipe blind holes of the present invention mainly includes: spindle box 1, No. 1 drilling and milling head 2, fixed chuck 3, machine tool base 4, horizontal adjustment seat 5, and No. 2 drill Milling head 6, linear slideway guide rail 7, linear ball screw 8, spiral chip removal machine 9, chip removal trolley 10, drag servo motor 11, screw nut 12 and left and right adjustment mechanism.

[0080] The structure of the machine base 4 is as Figure 8 As shown, the machine base 4 mainly includes: fixed support seat 401, No. 2 drilling and milling head mounting seat 402, fixed chuck mounting seat 403, linear ball screw mounting seat 404, No. 1 drilling and milling head mounting seat 405, and mounting seat 406 , Linear slide rail mounting seat 407, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com