Processing tool and processing method for novel net rack bolt ball

A bolt ball, a new type of technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of high maintenance and maintenance costs, not suitable for bolt ball processing, different angles, etc., to achieve maintenance and maintenance The effect of low cost, maximization of profit and improvement of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

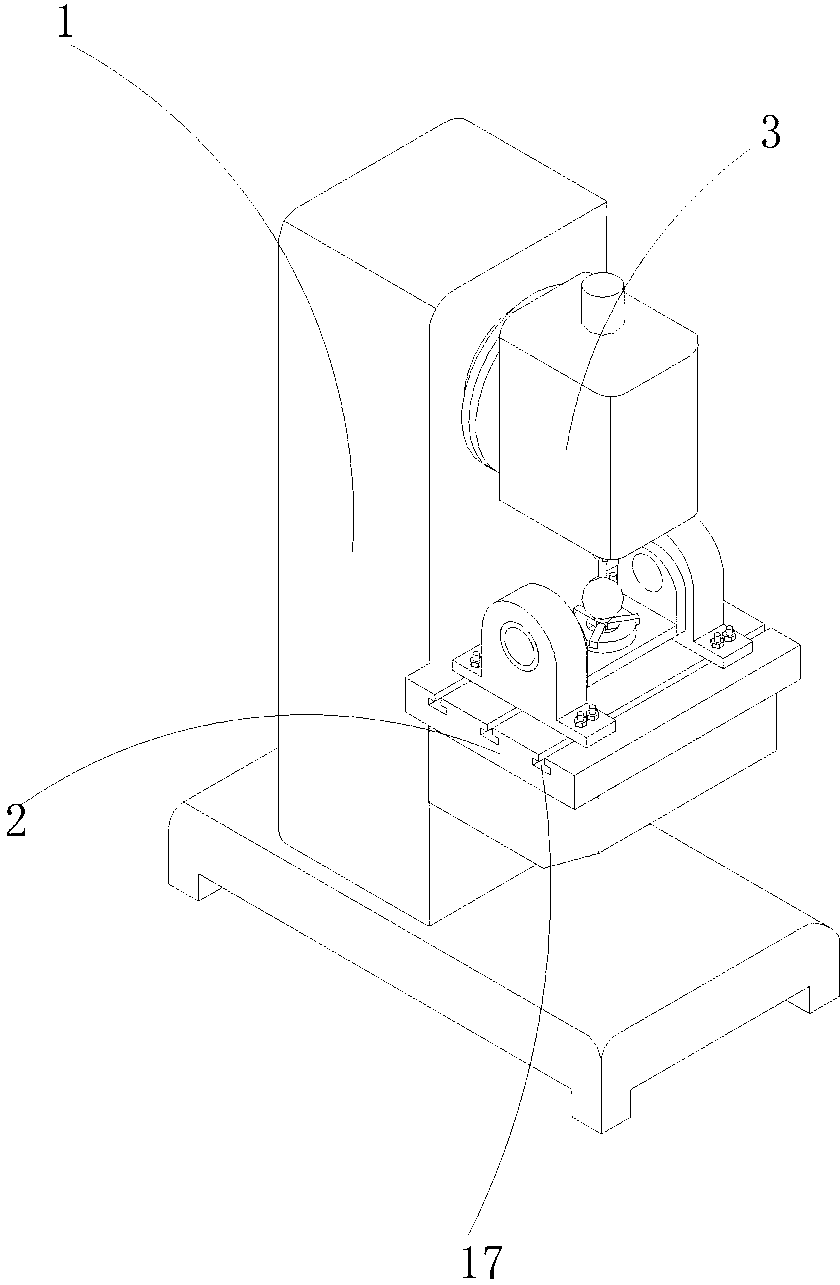

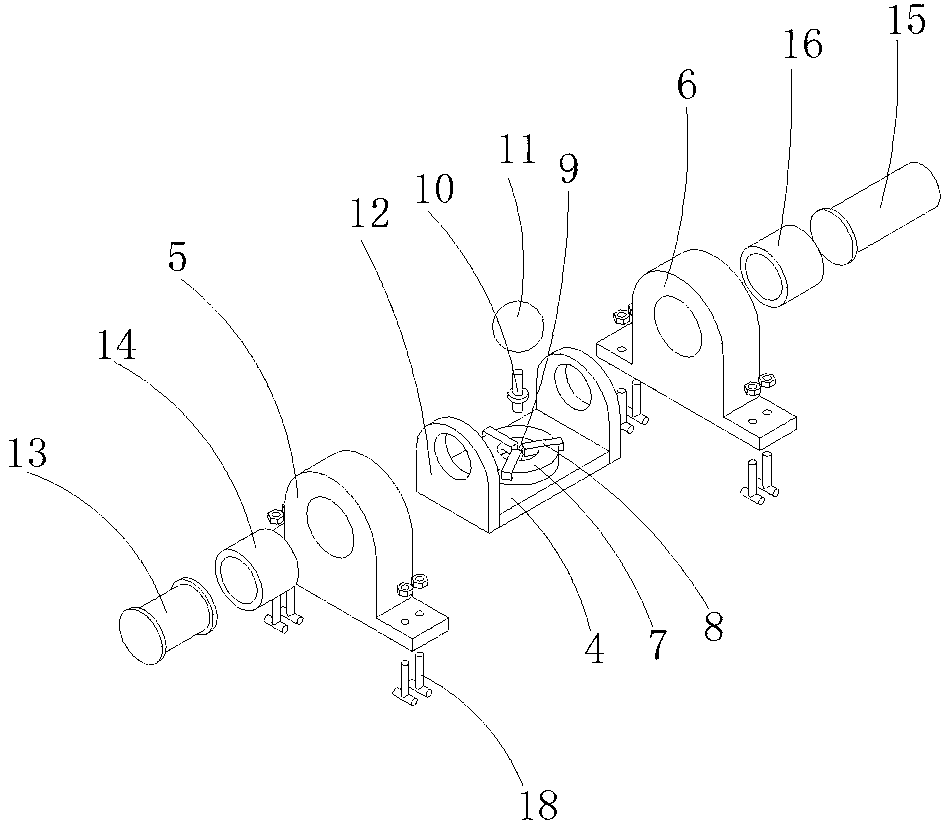

[0028] Embodiment 1: as figure 1 and figure 2 Shown, a kind of processing machine tool of novel network frame bolt ball, comprises vertical milling machine 1, is provided with operating platform 2 in described vertical milling machine 1, is provided with operating drill 3 above described operating platform 2, described The operation table 2 is provided with a numerically controlled indexing device fixed thereto. The numerically controlled indexing device includes a Y-axis indexing seat 4, and the left end of the Y-axis indexing seat 4 is provided with a corresponding Positioned left indexing base 5, the right end of the Y-axis indexing seat 4 is provided with a right indexing plate base 6 positioned therewith, and the Y-axis indexing seat 4 is provided with an X-axis Indexing chuck 7, described X-axis indexing chuck 7 is provided with evenly distributed card strips 8 that are slidably connected thereto, and card interface 9 is formed between the described card bars 8, and ...

Embodiment 2

[0038] Embodiment 2: A kind of processing machine tool of new-type network frame bolt ball, comprises vertical milling machine 1, is provided with operating platform 2 in described vertical milling machine 1, and the top of described operating platform 2 is provided with operating drill 3, so Said console 2 is provided with a numerically controlled indexing device fixed thereto, said numerically controlled indexing device comprises a Y-axis indexing seat 4, and said Y-axis indexing seat 4 is provided with a The left indexing plate base 5 positioned in phase, the right end of the Y-axis indexing seat 4 is provided with the right indexing plate base 6 positioned therewith, the Y-axis indexing seat 4 is provided with X Axis indexing chuck 7, described X-axis indexing chuck 7 is provided with evenly distributed card strips 8 that are slidably connected with it, and the card interface 9 is formed between the described card bars 8, and the described card interface 9 is provided wi...

Embodiment 3

[0048] Embodiment 3: A kind of processing machine tool of new grid bolt ball, comprises vertical milling machine 1, is provided with console 2 in described vertical milling machine 1, and the top of described console 2 is provided with operation drill 3, so Said console 2 is provided with a numerically controlled indexing device fixed thereto, said numerically controlled indexing device comprises a Y-axis indexing seat 4, and said Y-axis indexing seat 4 is provided with a The left indexing plate base 5 positioned in phase, the right end of the Y-axis indexing seat 4 is provided with the right indexing plate base 6 positioned therewith, the Y-axis indexing seat 4 is provided with X Axis indexing chuck 7, described X-axis indexing chuck 7 is provided with evenly distributed card strips 8 that are slidably connected with it, and the card interface 9 is formed between the described card bars 8, and the described card interface 9 is provided with a bolt ball center positioning pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clamping force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com