Length adjusting device for link of press machine

A technology of adjusting device and press, applied in the field of stamping and forming processing, can solve the problems of easy damage of worm gear, high scrap rate, tooth surface damage, etc., and achieve the effect of meeting processing accuracy requirements, real-time online control, and improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

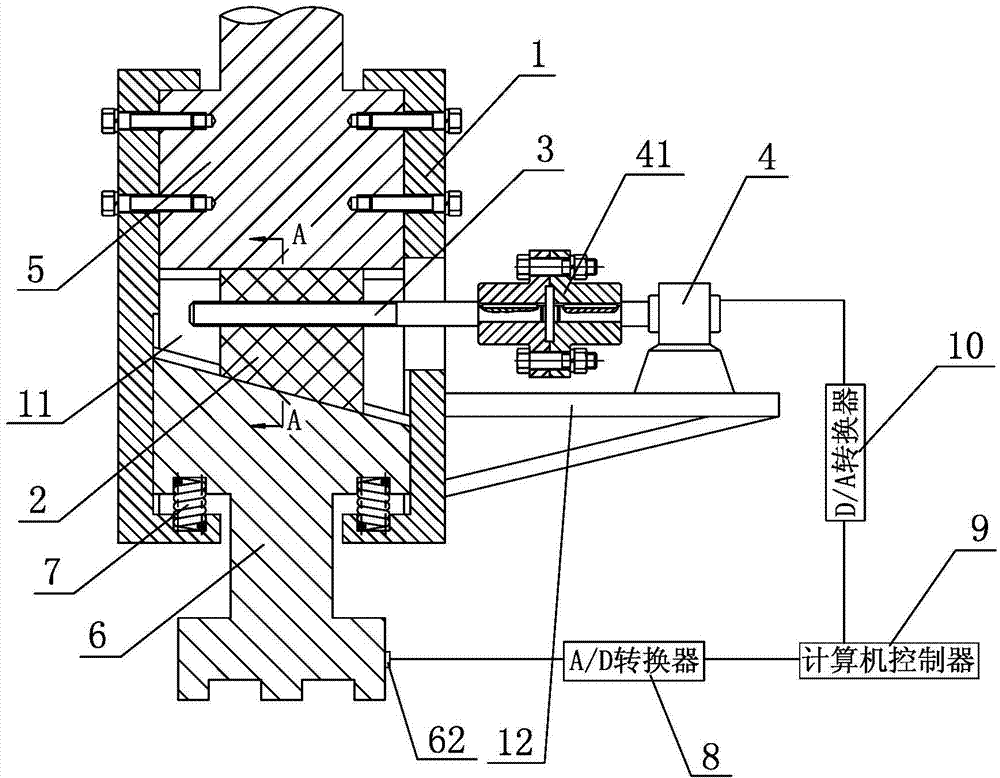

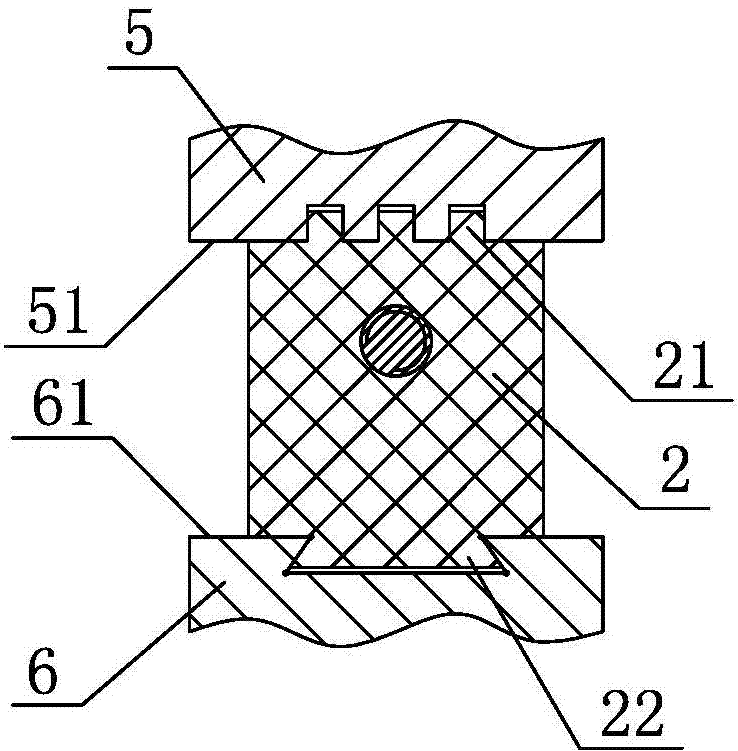

[0014] As shown in the figure, a device for adjusting the length of the connecting rod of a press includes a connecting frame 1, a wedge block 2, an adjusting screw 3, a motor 4 and a computer control system. The lower end of the connecting rod 5 in the press is fixedly connected by bolts In the connecting frame 1, the mold holder 6 for fixing the upper mold is arranged in the connecting frame 1 and slides up and down with the connecting frame 1. The lower end surface of the connecting rod 5 is a horizontal plane 51, and the upper end surface of the mold holder 6 For the oblique end surface 61 inclined downward to the right, a wedge-shaped space 11 is formed between the horizontal surface 51 of the lower end of the connecting rod 5 and the oblique end surface 61 of the upper end of the mold holder 6, and the shape of the wedge block 2 matches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com