Rotary-table center positioning method for spindle-driving-five-shafts machining center

A five-axis machining center and rotary table technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

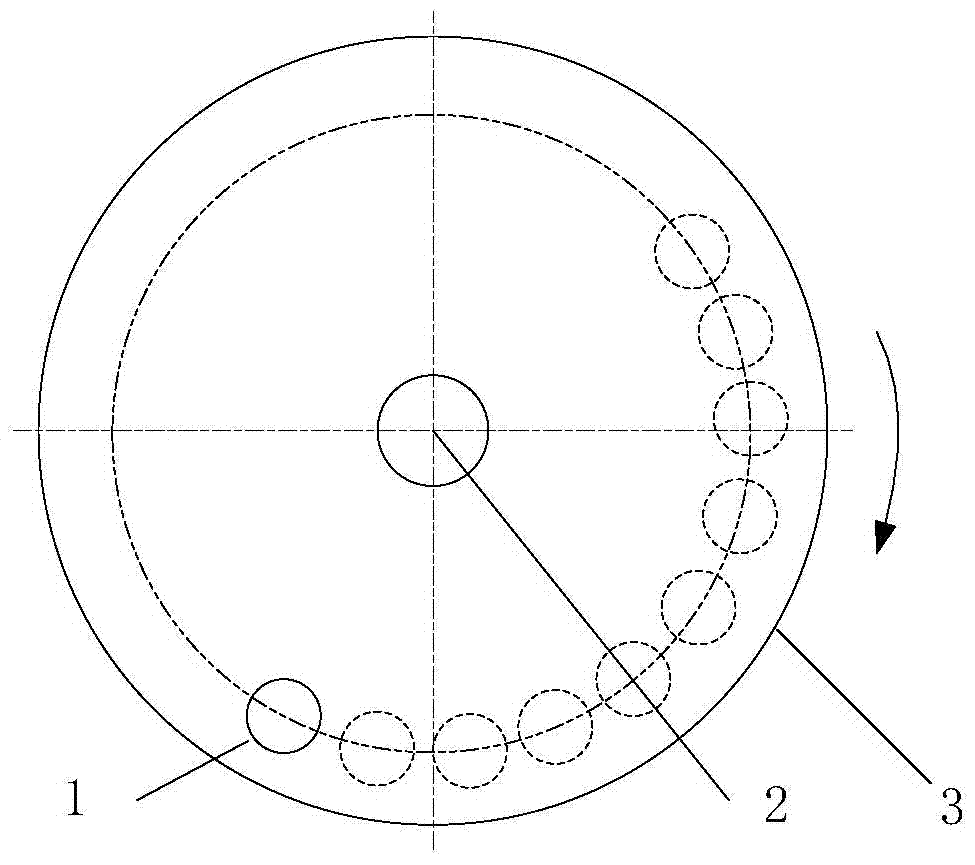

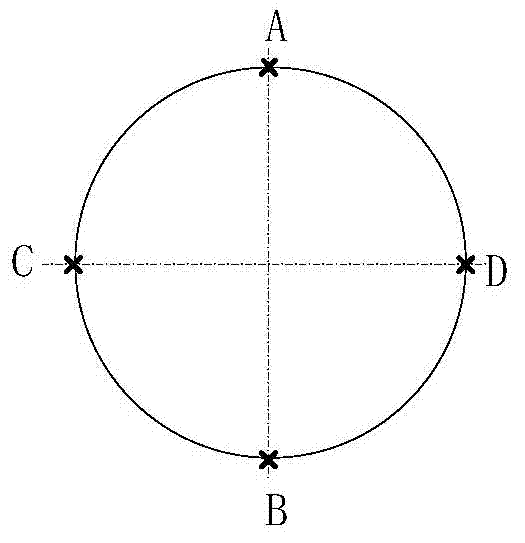

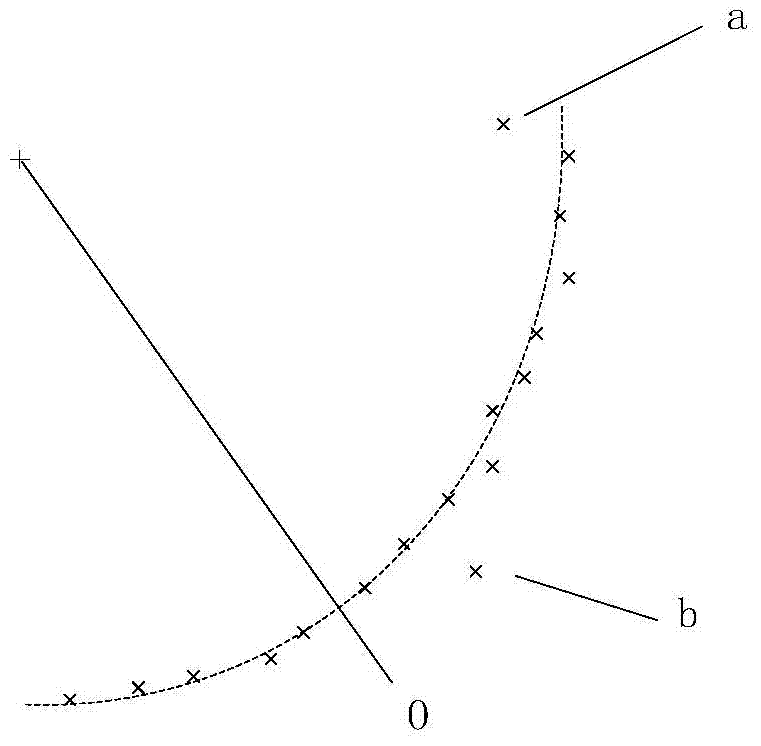

[0040] The following examples refer to Figure 1-3 .

[0041] Step 1: place and fix a ring gauge 1 on the rotary table 3 of the spindle swing five-axis machining center;

[0042]Requirement a: The inner hole diameter d of the ring gauge 1 (20mm≤d≤50mm) is convenient for the machine tool spindle to find the center of the ring gauge 1, the parallelism of the upper and lower end faces of the ring gauge 1≤0.005, and the perpendicularity between the end face of the ring gauge 1 and the central axis≤ 0.005, ring gauge 1 central hole roundness ≤ 0.005. Fix the ring 1 gauge at a position as far away from the center 2 of the rotary table as possible, and in the end milling state, the center of the ring gauge 1 that the spindle can reach;

[0043] Requirement b: The ring gauge 1 is installed horizontally on the workbench 3, and the parallelism between the end face and the workbench 3 is ≤0.005.

[0044] Step 2: The spindle swings. The five-axis machining center is in the end milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com