Speed connection method for numerical control system

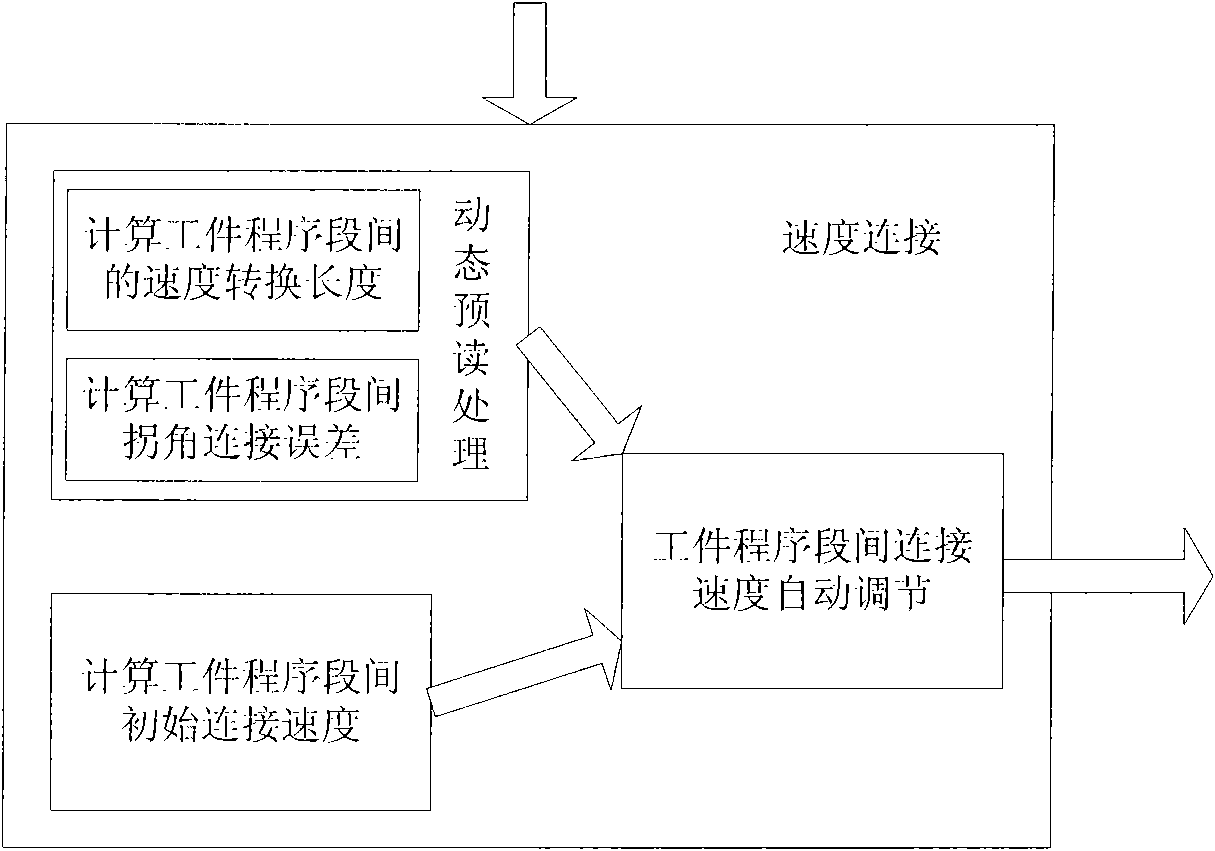

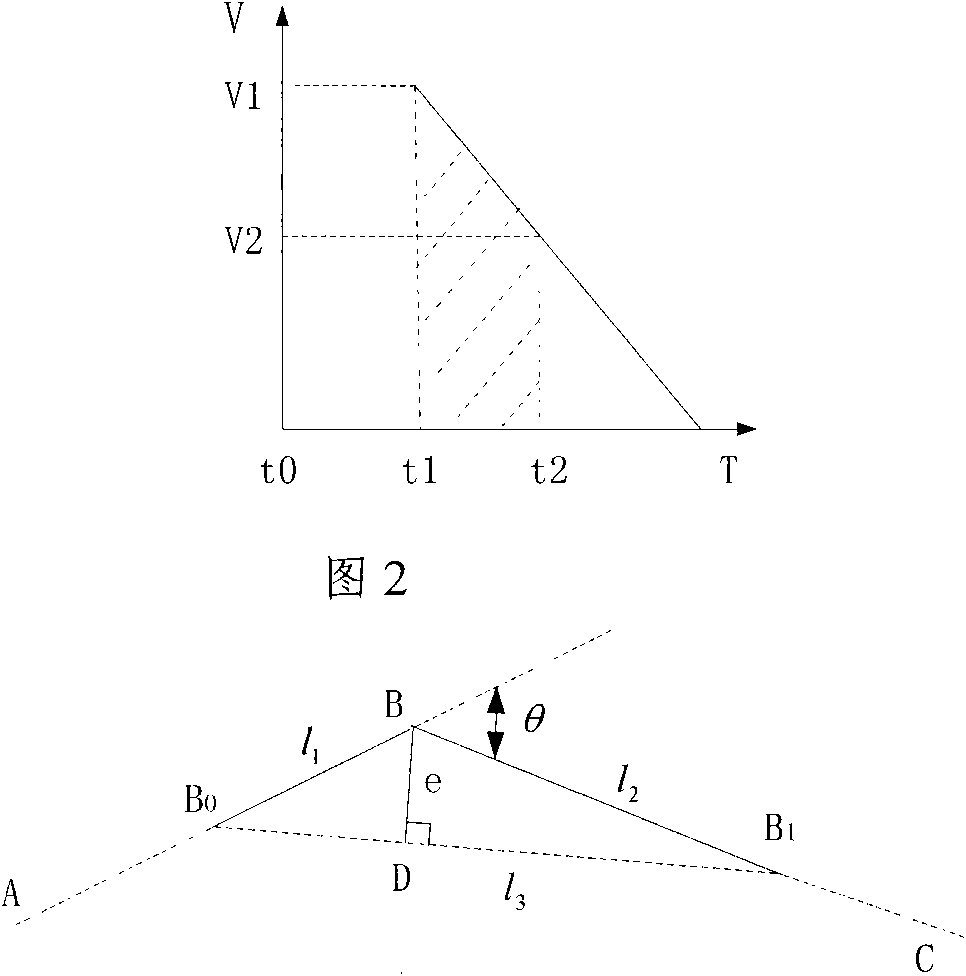

A technology of numerical control system and connection method, applied in the direction of digital control, electrical program control, etc., can solve problems such as difficult to analyze the connection error of adjacent workpiece program segments, difficult to achieve programmed feed speed, difficult precision and speed optimization combination of numerical control machine tools, etc. , to achieve the effect of high smoothness, smooth transition of speed and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

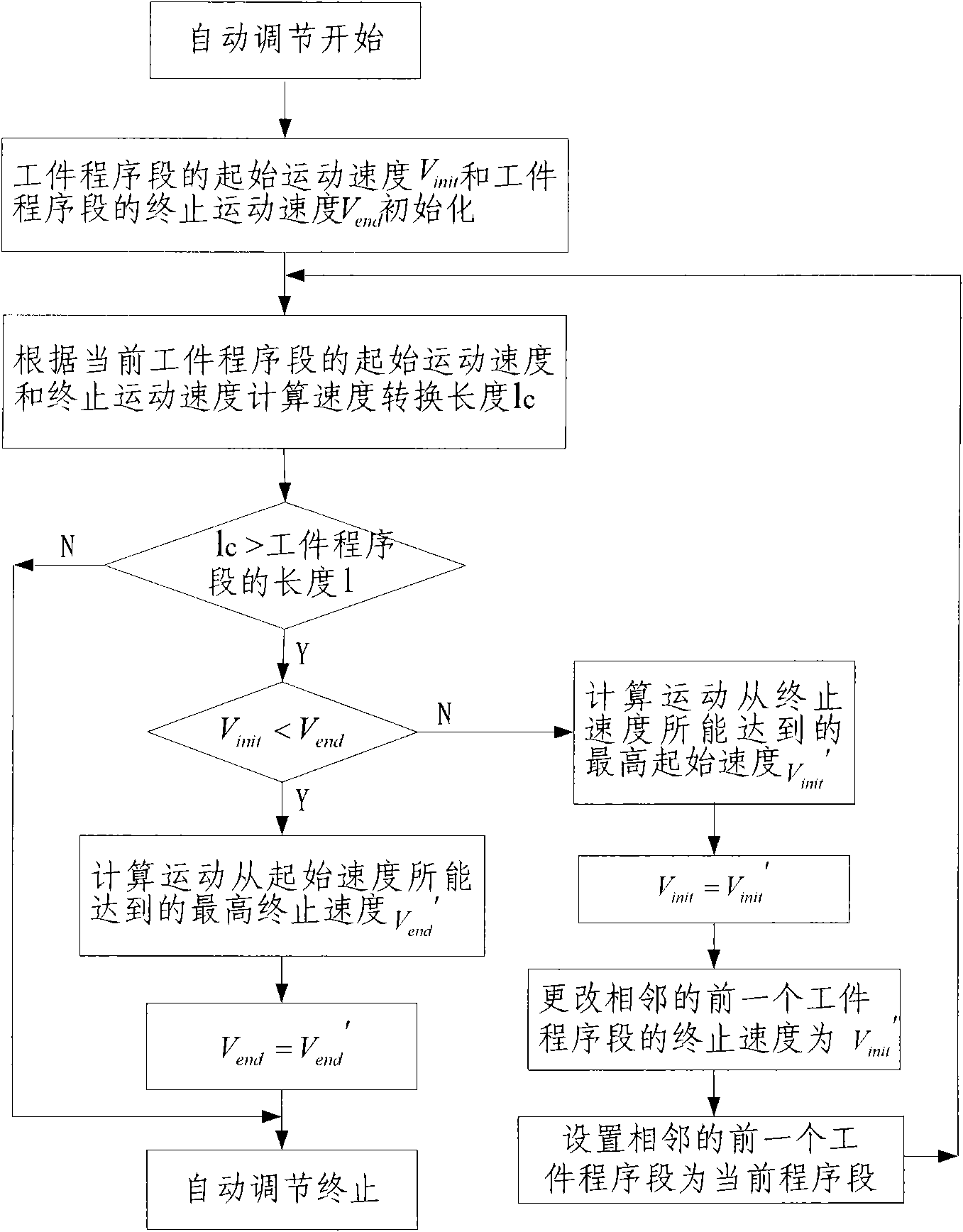

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041]In this embodiment, the method of the present invention is applied to the speed connection processing of the open CNC system motion control part of the blue sky hardware platform. The acceleration and deceleration mode is linear acceleration and deceleration, and the operation results are verified on the three-axis CNC milling machine.

[0042] The hardware platform adopts standard industrial-grade IPC boards, 5X86-133MHz CPU is used as the system controller, and a 4+1-axis controller is composed of a 10,000-gate programmable FPGA device. At the same time, the FPGA device provides other auxiliary circuits such as CNC system I / O.

[0043] The main technical parameters of the test environment are as follows:

[0044] Drive: Yaskawa Electric ΣII series AC servo motor;

[0045] CNC system: CPU 5X86-133MHz, RAM-32M, FLASH-32M, I / O-32 / 24, encoder input-4, D / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com