Machining device for drilling and tapping inside small space

A processing device, small space technology, applied in the field of machinery, to achieve the effect of compact structure, suitable for mass production and processing, and exquisite conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

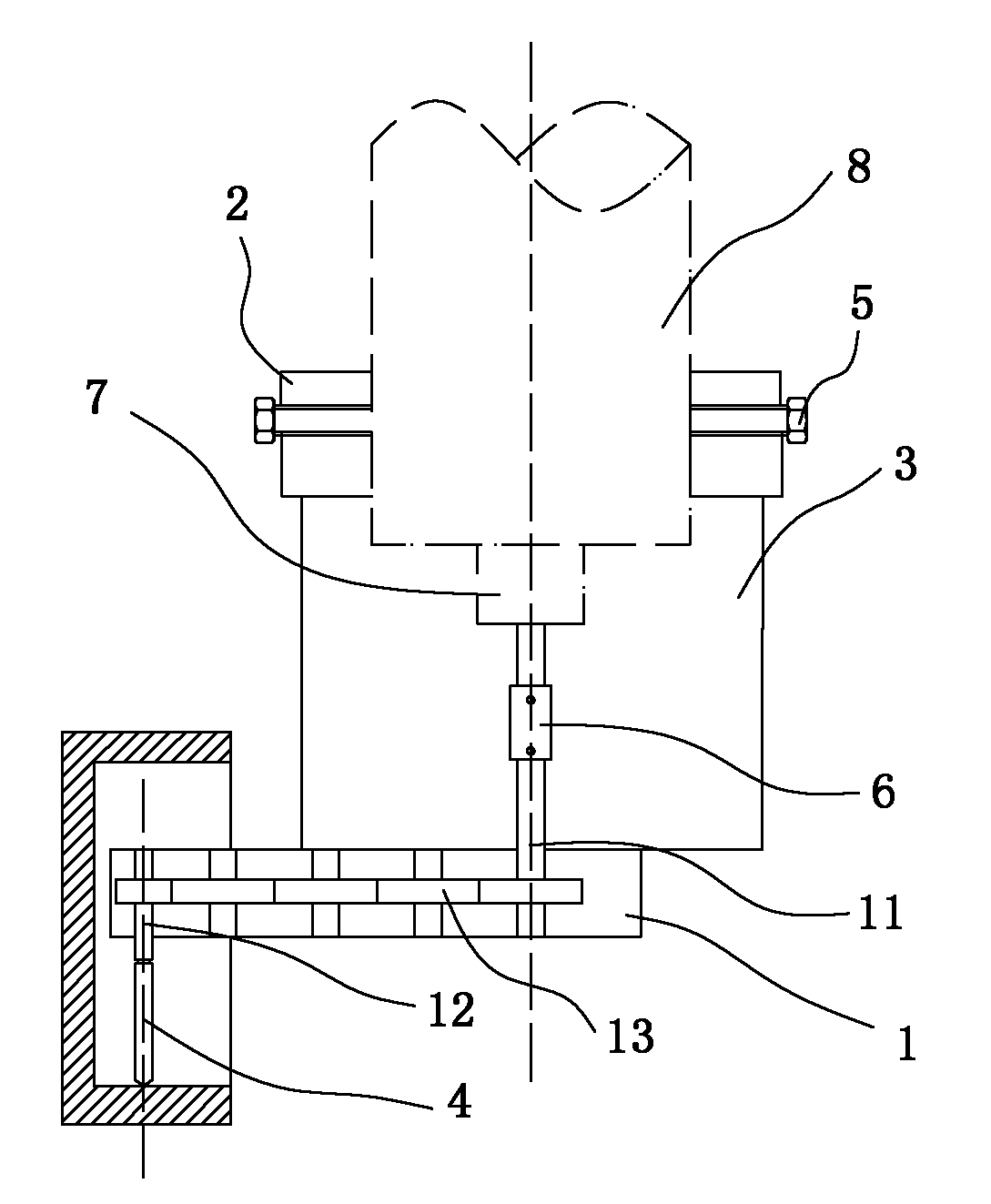

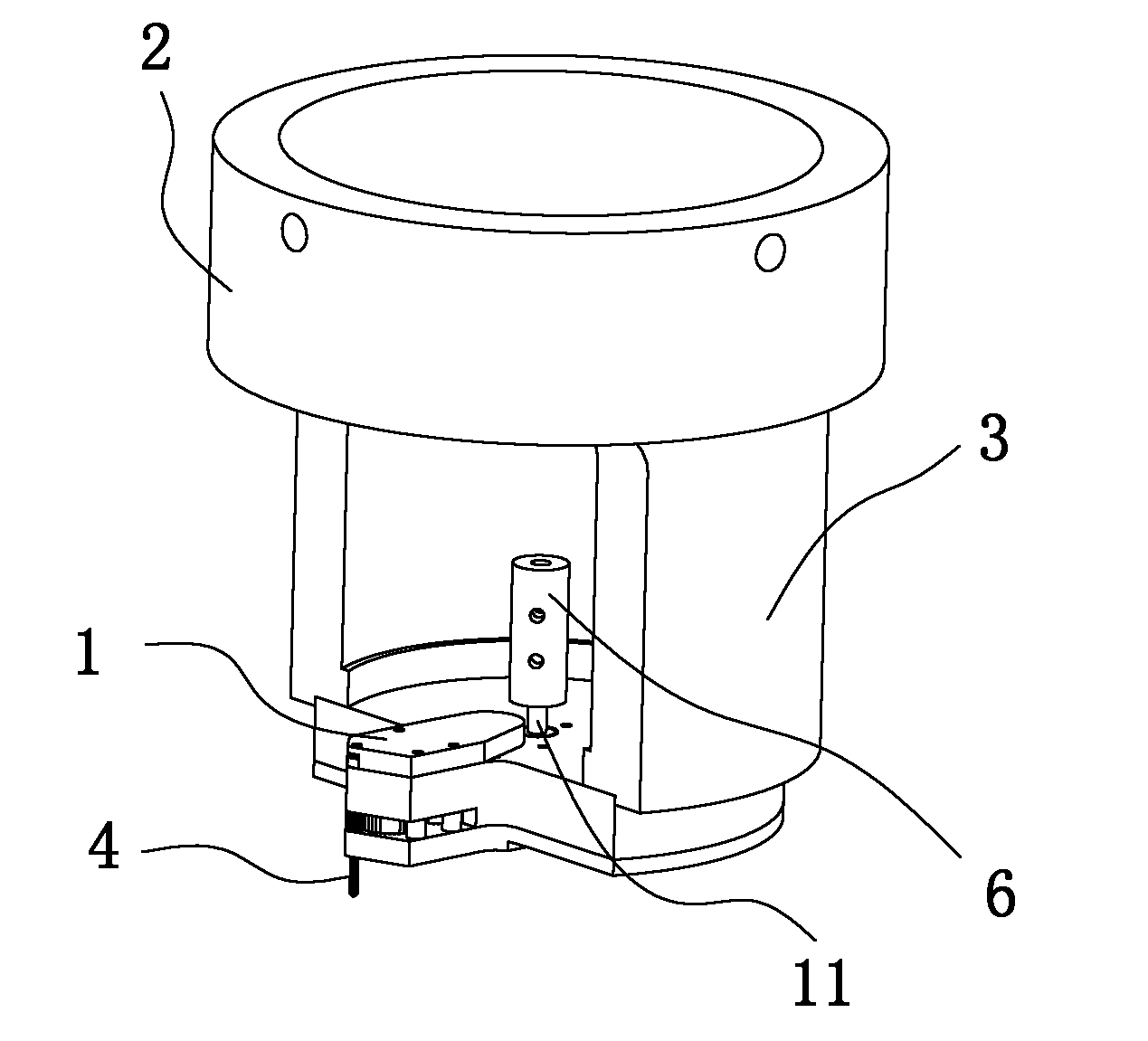

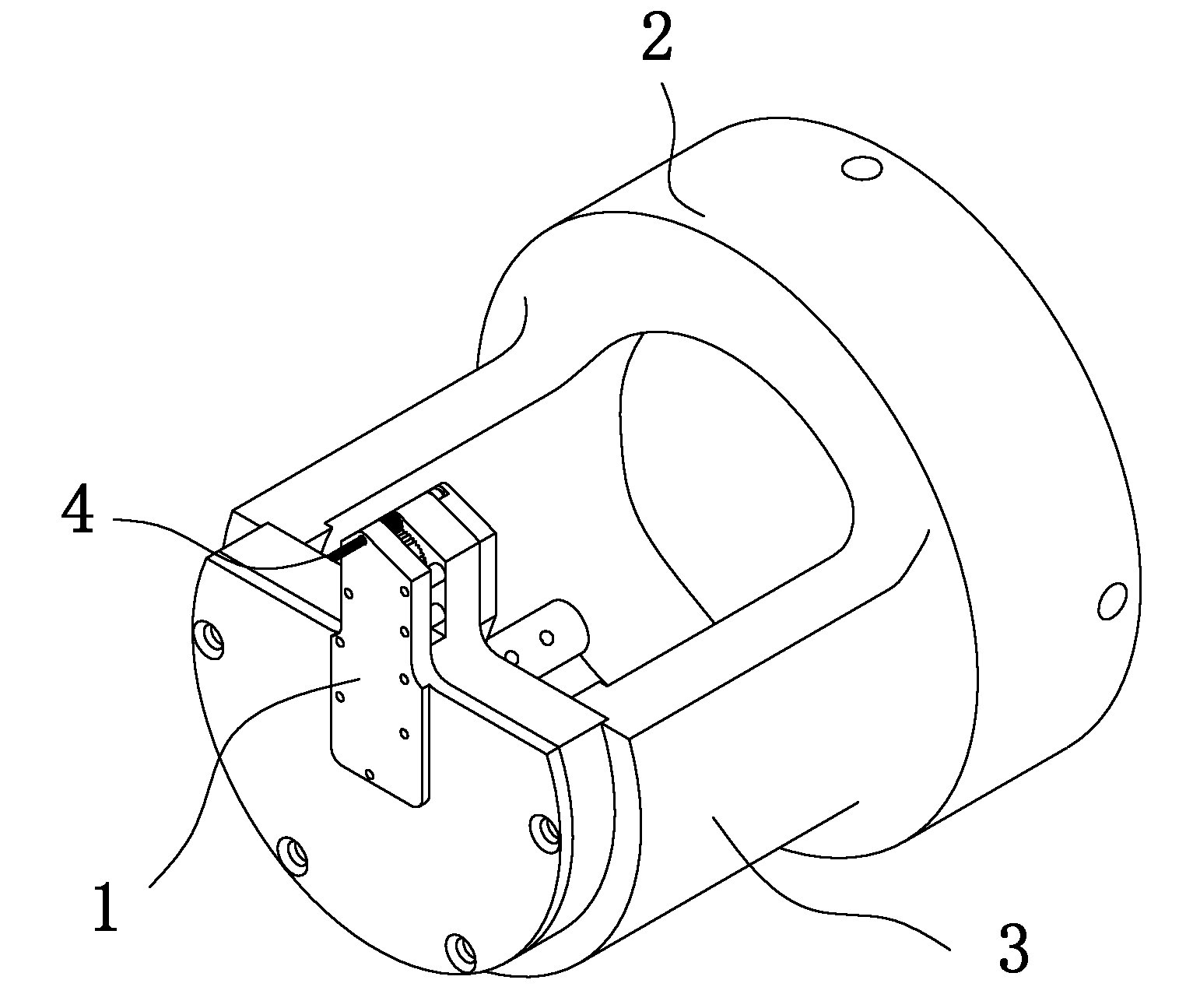

[0014] Such as Figure 1-3 As shown, the small space processing device of the present invention includes a gear box 1 and an axle sleeve 2 for connecting the chuck 7 of the drilling and tapping equipment; the gear box 1 has an input shaft 11 and an output shaft 12, and the input The shaft 11 and the output shaft 12 rotate in the same direction and are parallel to each other. The input shaft 11 protrudes from the top surface of the gearbox 1 and coincides with the axis of the sleeve 2; The bottom surface of the case 1 protrudes. The tool 4 is coupled with an output shaft 12 .

[0015] In the gearbox 1, the input shaft 11 and the output shaft 12 are connected through an odd number of transmission gears 13 meshing with each other. To ensure that the selection directions of the input shaft 11 and the output shaft 12 are consistent, when selecting gears, the corresponding size and transmission ratio can be selected as required to meet the requirements of the deviation distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com