Preparation method and application of antibacterial bio-ceramic film with titanium or titanium alloy surface containing copper

A bioceramic membrane and titanium alloy technology, applied in surface reaction electrolytic coating, drug delivery, tissue regeneration, etc., can solve the problems of surface passivation film damage, large friction coefficient of titanium alloy, poor wear resistance, etc. Effects of abrasion and corrosion resistance, high biological activity and bacteriostatic properties, high protein adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Material preparation: After the pure titanium is cut and polished, it is cleaned and degreased by ultrasonic waves in acetone solution.

[0052] 2. Sandblasting: The silica sand particle size for sandblasting is 0.2mm, the compressed air strength is 0.2MPa, the surface roughness of the obtained substrate is Ra3.0μm, and the sandblasting equipment is RH-1010P high-pressure dry sandblasting machine.

[0053] 3. Chemical passivation: In the passivation solution, 40% (volume concentration) HF is 2ml / L, 70% (volume concentration) HNO 3 10ml / L, citric acid 1ml / L, and the rest is water. Temperature: room temperature, process for 2 minutes, immediately wash with tap water for 1 to 2 minutes after taking it out, and then wash with deionized water for 1 to 2 minutes, the thickness of the passivation film is 1 μm.

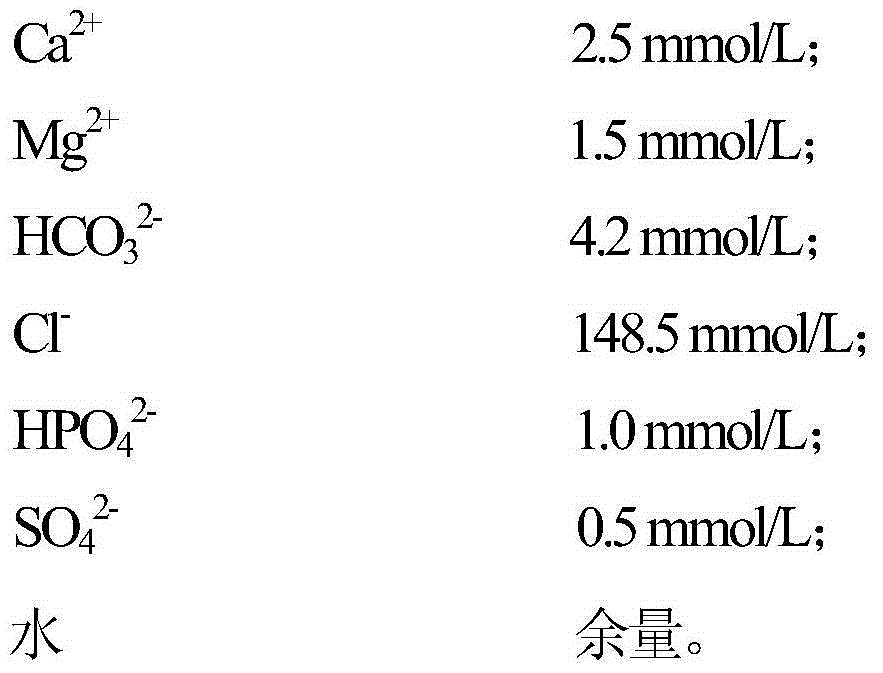

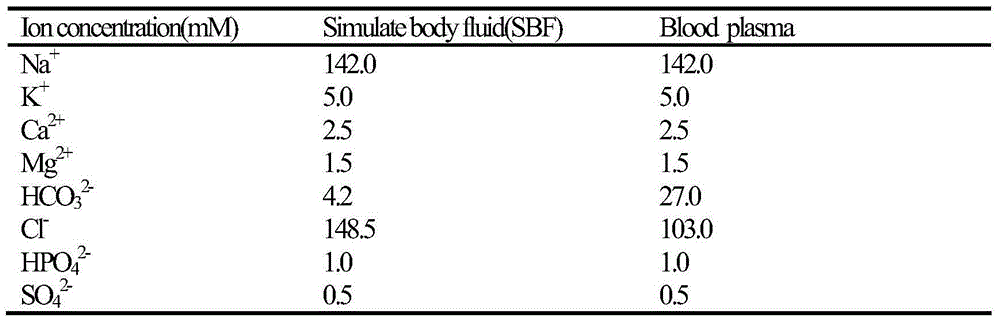

[0054] 4. Preparation of single forward square wave pulse micro-arc oxidation ceramic film: Electrolyte: calcium acetate with a concentration of 0.3mol / L, sodium g...

Embodiment 2

[0061] 1. Material preparation: After the pure titanium is cut and polished, it is cleaned and degreased by ultrasonic waves in acetone solution.

[0062] 2. Sandblasting: the silica sand particle size for sandblasting is 0.6mm, the compressed air strength is 0.6MPa, the surface roughness of the obtained substrate is Ra4.0μm, and the sandblasting equipment is RH-1010P high-pressure dry sandblasting machine.

[0063] 3. Chemical passivation: passivation solution: 40% (volume concentration) HF is 2ml / L, 70% (volume concentration) HNO 3 8ml / L, tartaric acid 2ml / L, and the rest is water. Temperature: room temperature, treat for 3 minutes, wash with tap water for 1 to 2 minutes immediately after taking it out, and then wash with deionized water for 1 to 2 minutes, the passivation film thickness is 1 μm.

[0064] 4. Micro-arc oxidation ceramic membrane preparation: Electrolyte: 0.2mol / L calcium acetate and 0.01mol / L calcium citrate, 0.01mol / L sodium dihydrogen phosphate, 0.005mol / L...

Embodiment 3

[0071] 1. Material preparation: Titanium alloy (Ti6Al4V) is cleaned and degreased by ultrasonic cleaning in acetone solution after cutting and grinding.

[0072] 2. Sandblasting: the silica sand particle size for sandblasting is 1.2mm, the compressed air strength is 0.5MPa, the surface roughness of the obtained substrate is Ra5.0μm, and the sandblasting equipment is RH-1010P high-pressure dry sandblasting machine.

[0073] 3. Chemical passivation: in the passivation solution, 70% (volume concentration) HNO 3 4ml / L, 70% (volume concentration) HNO 3 10ml / L, oxalic acid 1ml / L, and the rest is water. Temperature: room temperature, treat for 5 minutes, wash with tap water for 1 to 2 minutes immediately after taking it out, and then wash with deionized water for 1 to 2 minutes, the thickness of the passivation film is 1 μm.

[0074] 4. Micro-arc oxidation ceramic membrane preparation: Electrolyte: concentration of 0.1mol / L calcium glycerophosphate and 0.2mol / L calcium acetate, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com