Ultrasonic square wave direct current pulse arc-welding power supply device

A DC pulse and arc welding power supply technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficulties, current waveform distortion, and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

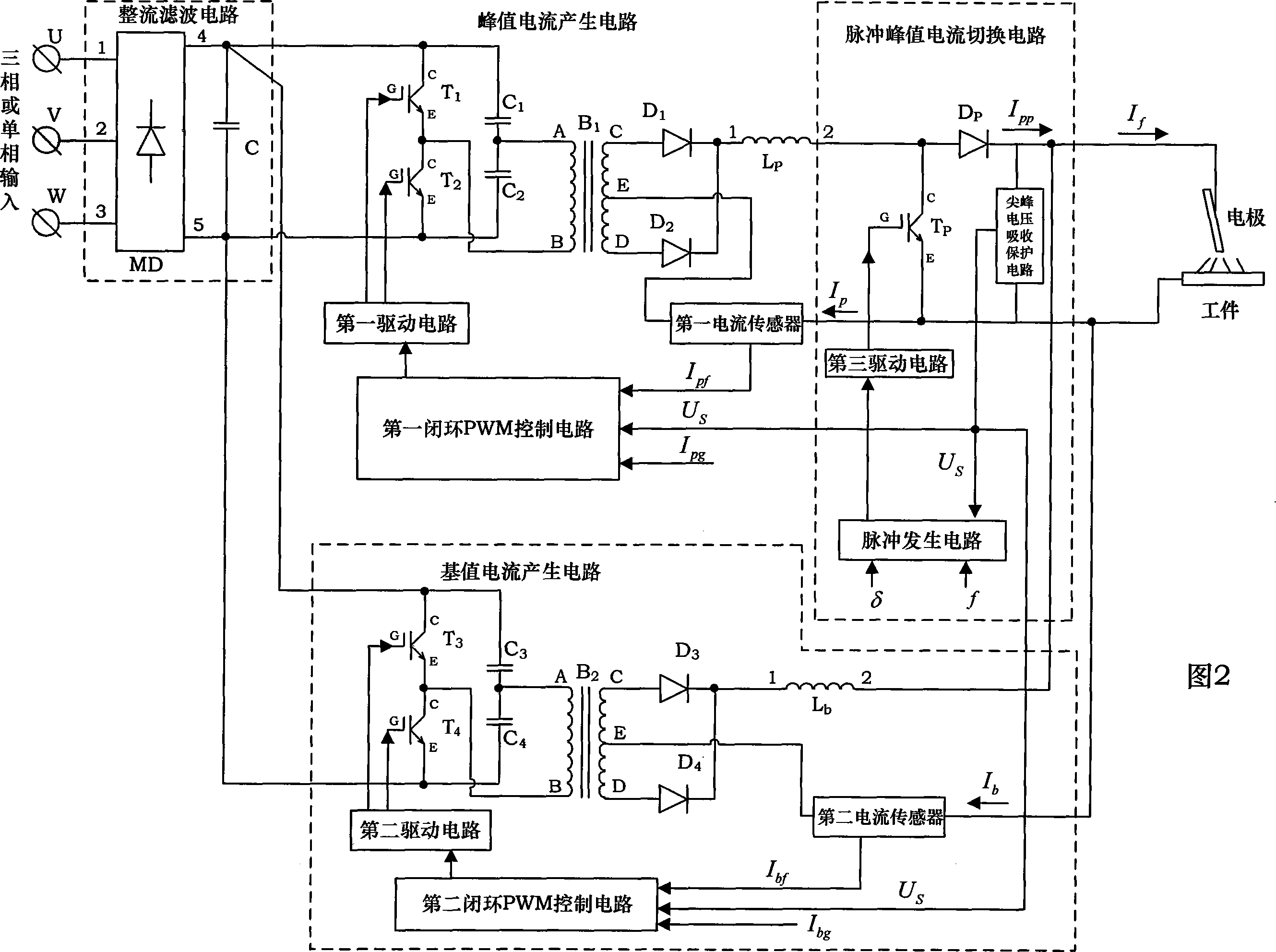

[0014] Referring to Fig. 2, the super-audio frequency square wave DC pulsed arc welding power supply device of the present invention is composed of a pulse peak current switching circuit, a base value current generating circuit, a peak current generating circuit, and a rectifying and filtering circuit;

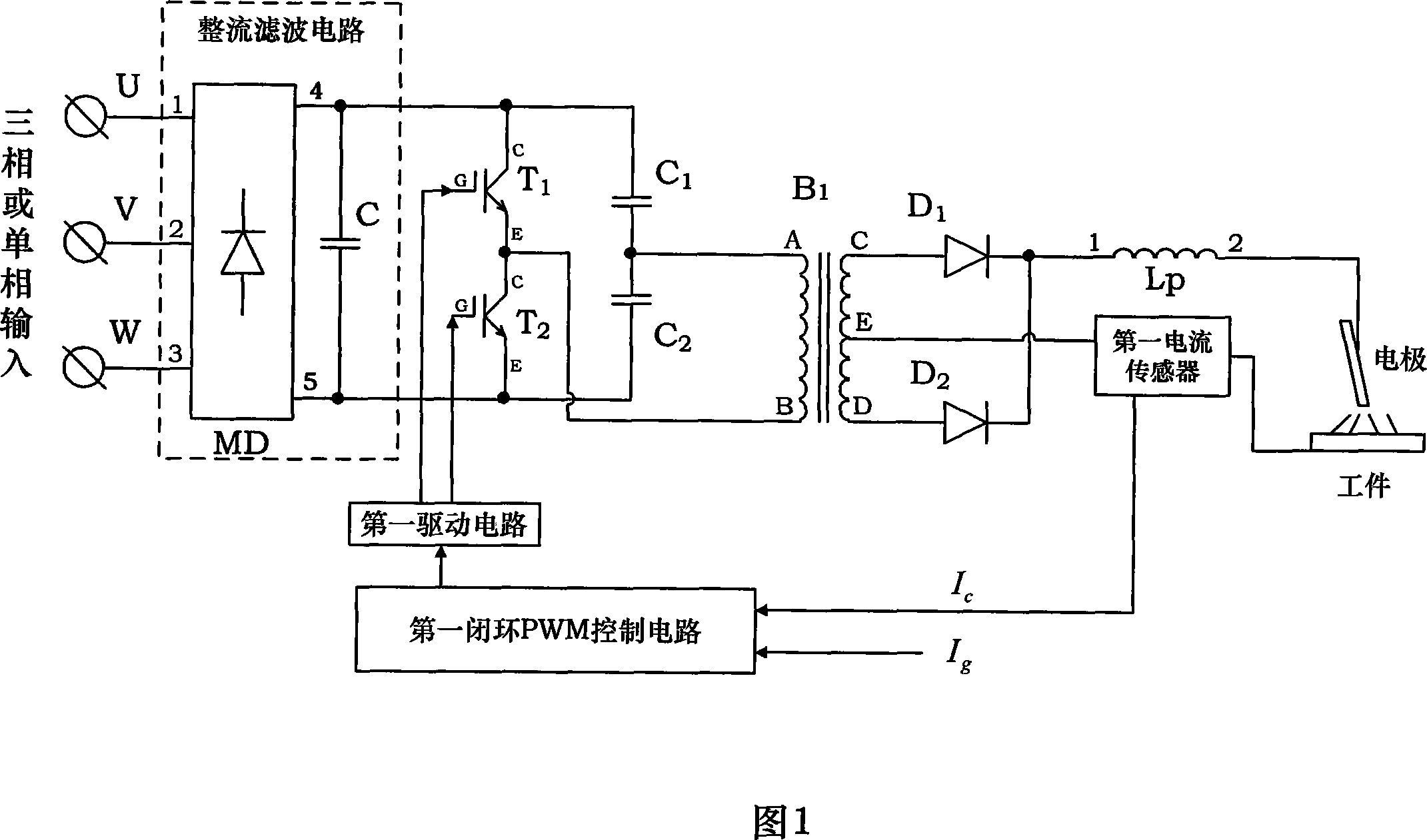

[0015] In the present invention, the rectifying and filtering circuit and the peak current generating circuit adopt a conventional structure as shown in FIG. 1 . That is, the rectification filter circuit may be composed of a rectifier bridge MD and a filter capacitor C. The peak current generating circuit consists of a half-bridge inverter circuit, a first transformer B 1 , the first diode D 1 , the second diode D 2 , Freewheeling inductance L P , a first current sensor, a first drive circuit, and a first closed-loop PWM control circuit. The connections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com