Preparation method of indium tin oxide (ITO) ceramic target material

A technology of indium tin oxide and ceramic targets, which is applied in the field of optoelectronic materials, can solve the problems of difficult control of target density, reduced sputtering uniformity, and increased oxygen loss, so as to reduce density and sintering temperature and reduce production costs , enhance the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

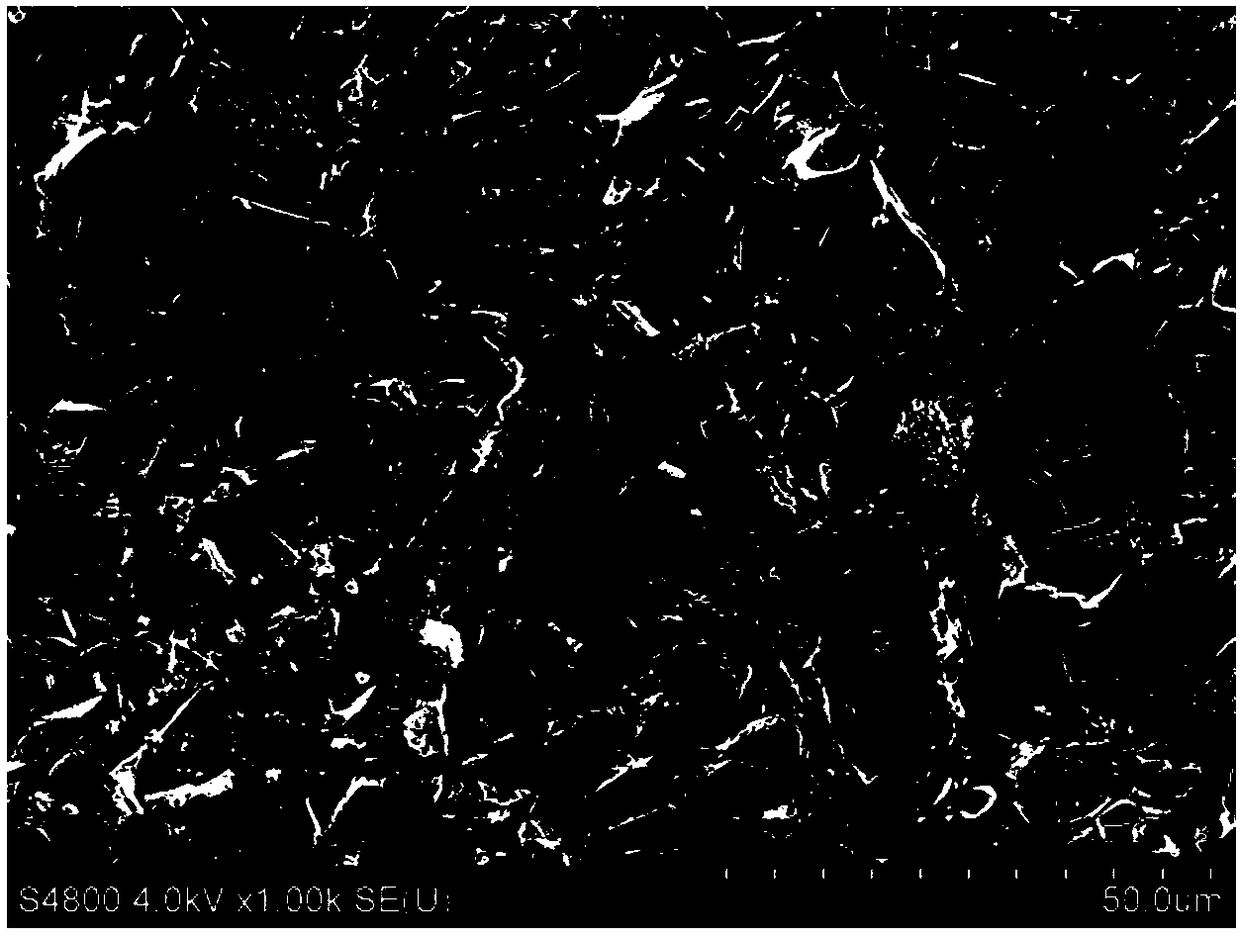

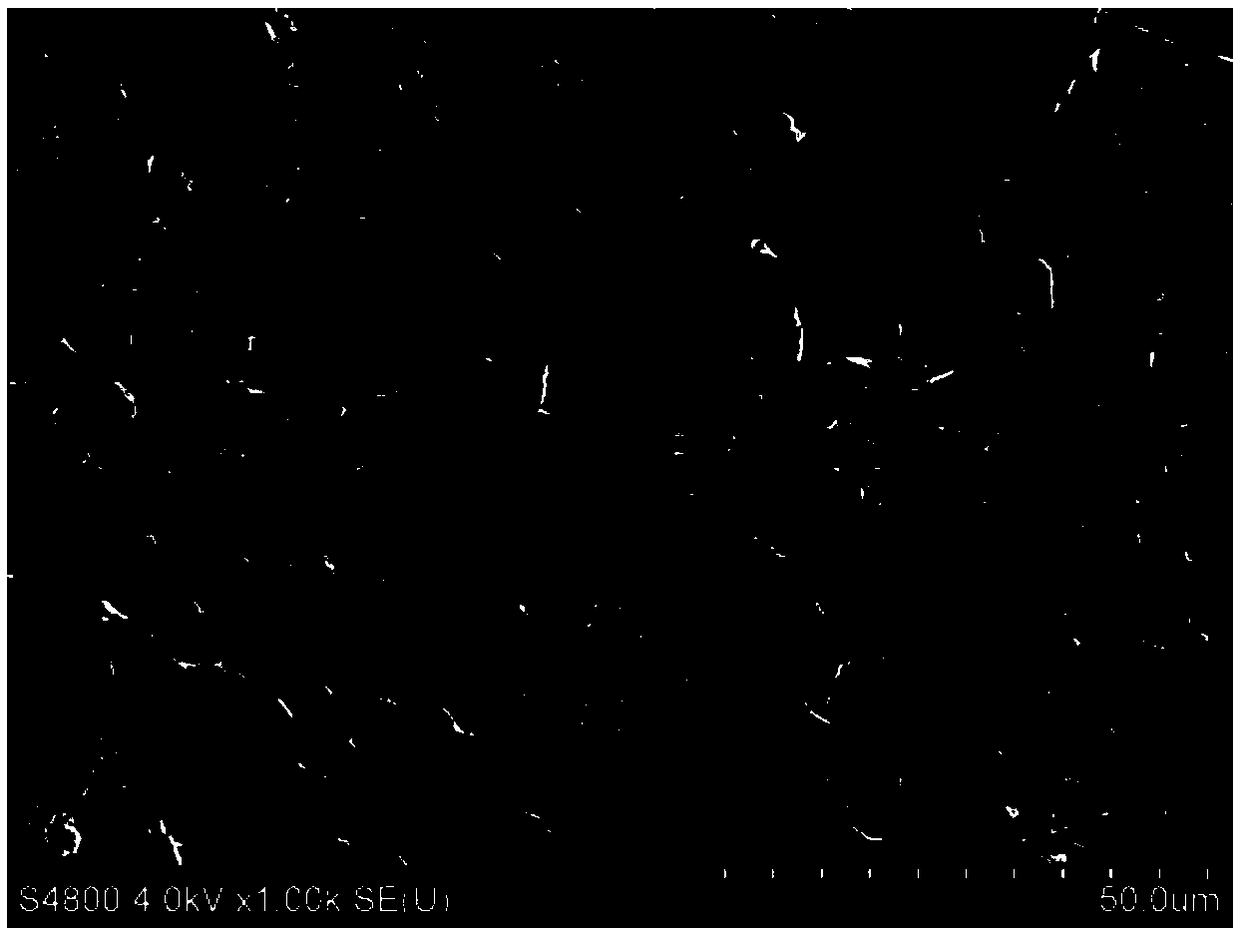

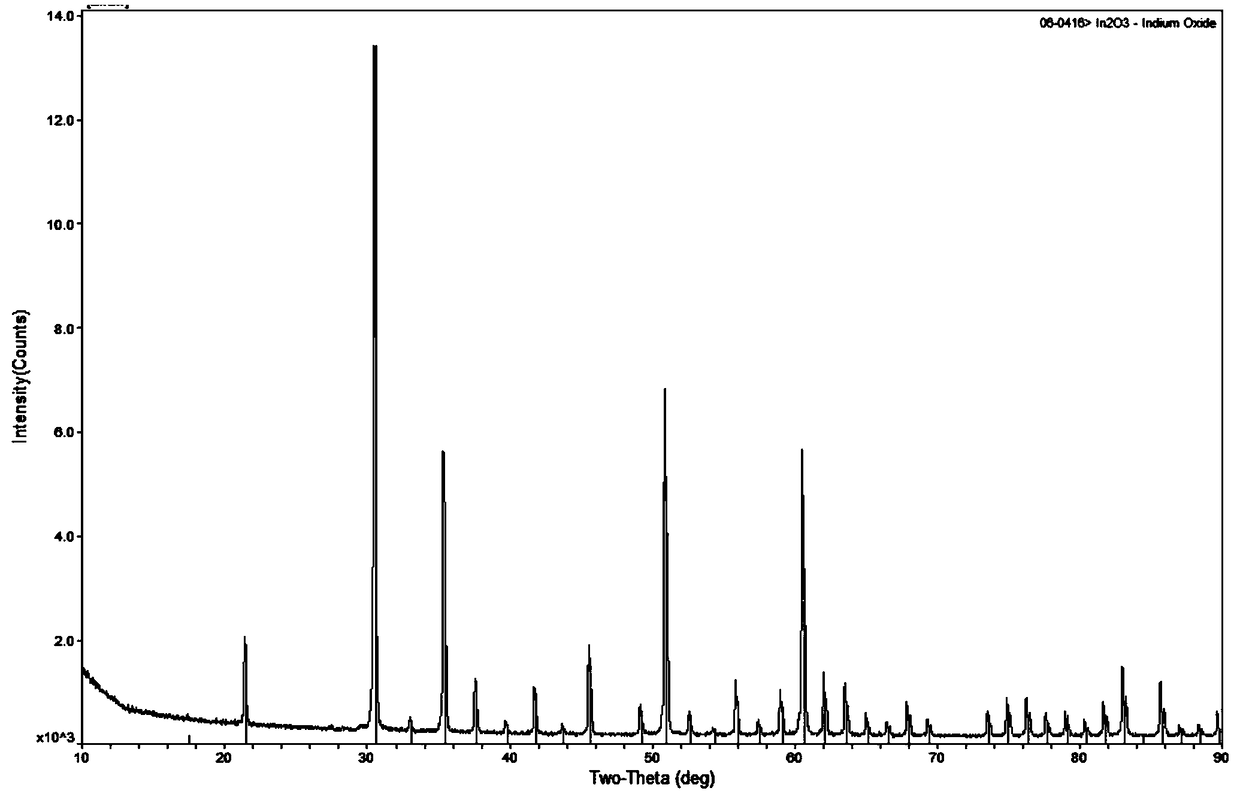

Image

Examples

Embodiment 1

[0029] The preparation method of the indium tin oxide ceramic target of embodiment 1 comprises the following steps:

[0030] Step 1. Forming of the indium tin oxide ceramic body:

[0031] (1) Mix a certain amount of high-purity indium oxide powder with high-purity tin oxide powder to obtain a mixed powder. The mass ratio of tin oxide powder to indium oxide powder in the mixed powder is 1:9 , wherein the crystal form of the high-purity indium oxide powder is a cubic phase structure, the particle size is 250 nm, and the purity is >99.99 %; the particle size of the high-purity tin oxide powder is 50 nm, and the purity is >99.99 %;

[0032] (2) Pour the mixed powder into deionized water containing 1.5 wt% polyvinylpyrrolidone, and form a slurry after 12 h of ball milling;

[0033] (3) Take out the slurry, dry it in an oven at 80°C, and then grind it and pass it through a 100-mesh sieve to form dry powder A;

[0034] (4) Mix 1 part of powder A with 0.1 part of deionized water con...

Embodiment 2

[0040] The preparation method of the indium tin oxide ceramic target of embodiment 2 comprises the following steps:

[0041] Step 1. Forming of the indium tin oxide ceramic body:

[0042](1) Mix a certain amount of high-purity indium oxide powder with high-purity tin oxide powder to obtain a mixed powder. The mass ratio of tin oxide powder to indium oxide powder in the mixed powder is 1:9 , wherein the crystal form of the high-purity indium oxide powder is a cubic phase structure, the particle size is 350 nm, and the purity is >99.99 %; the particle size of the high-purity tin oxide powder is 150 nm, and the purity is >99.99 %;

[0043] (2) Pour the mixed powder into deionized water containing 0.5 wt% polyvinyl alcohol, and form a slurry after 8 h of ball milling;

[0044] (3) Take out the slurry, dry it in an oven at 60°C, and then grind it and pass it through a 100-mesh sieve to form dry powder A;

[0045] (4) Mix 1 part of powder A with 0.05 part of deionized water contai...

Embodiment 3

[0051] The preparation method of the indium tin oxide ceramic target of embodiment 3 comprises the following steps:

[0052] Step 1. Forming of the indium tin oxide ceramic body:

[0053] (1) Mix a certain amount of high-purity indium oxide powder with high-purity tin oxide powder to obtain a mixed powder. The mass ratio of tin oxide powder to indium oxide powder in the mixed powder is 1:9 , wherein the crystal form of the high-purity indium oxide powder is a cubic phase structure, the particle size is 450 nm, and the purity is >99.99 %; the particle size of the high-purity tin oxide powder is 200 nm, and the purity is >99.99 %;

[0054] (2) Pour the mixed powder into deionized water containing 2.7 wt% carboxymethyl cellulose, and form a slurry after 18 h of ball milling;

[0055] (3) Take out the slurry, dry it in an oven at 95°C, and then grind it and pass it through a 100-mesh sieve to form dry powder A;

[0056] (4) Mix 1 part of powder A with 0.18 part of deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com