Preparation method of nano-silver antibacterial real silk

A nano-silver antibacterial and silk technology, used in textiles and papermaking, fiber processing, animal fibers, etc., can solve the problems of poor antibacterial washability, not long-lasting antibacterial performance, and staying binding force of antibacterial agents to achieve long-term antibacterial properties. Functional washability, long-lasting antibacterial function, strong adhesion and deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

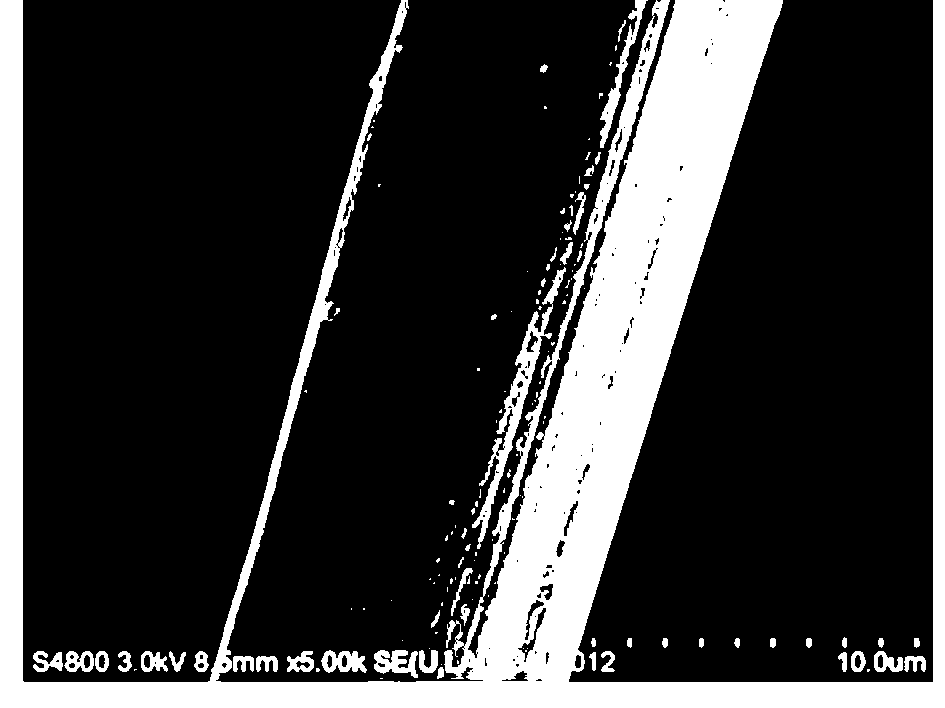

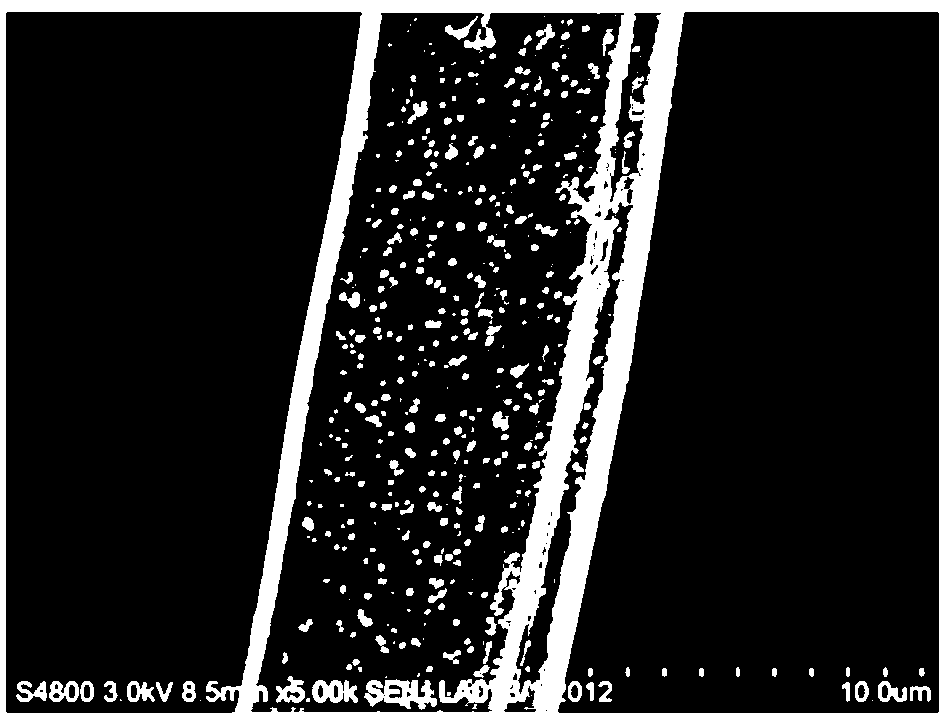

Image

Examples

Embodiment 1

[0025] The aloe leaves are washed with deionized water and peeled to obtain inner denim, and then cut into pieces, crushed, filtered, separated and purified to obtain the aloe leaf extract. Disperse the aloe leaf extract in deionized water, prepare 150ml volume percent concentration of 20% aloe leaf extract aqueous solution, add 7.5ml concentration of 0.05wt% amino terminal hyperbranched compound aqueous solution, mix well to obtain a composite solution, place in After freezing at -20°C for 3 hours, thawing at room temperature for 6 hours, and 2 cycles of freezing and thawing, the pH value of the composite solution was adjusted to 10.5 with NaOH solution to obtain a uniform and stable dispersion of aloe vera leaf extract.

[0026] Prepare 250ml of calcium nitrate solution with a concentration of 20wt%, mix it with 5ml of a sericin solution with a molecular weight of 1-20KDa and a concentration of 2wt%, the molecular weight of sericin is 1-20KDa, to obtain a neutral sericin salt...

Embodiment 2

[0029] Wash the cactus leaves with deionized water and peel them to obtain inner denim, then cut into pieces, pulverize, filter, separate and purify to obtain cactus leaf extracts, disperse the extracts in deionized water, and prepare 350ml volume percentage of 30% Add 7ml aqueous solution of amino-terminated hyperbranched compound with a concentration of 0.5wt% to the aqueous solution of cactus leaf extract, mix well to obtain a composite solution, freeze at -20°C for 4 hours, thaw at room temperature, freeze-thaw cycle 3 times, use NaOH solution adjusted its pH value to 10.8 to obtain a uniform and stable cactus leaf extract dispersion.

[0030]Prepare 500ml of calcium chloride solution with a concentration of 25wt%, and mix it with 10ml of a silk fibroin solution with a concentration of 1.0wt%. The molecular weight of silk fibroin is 1-20KDa to obtain a neutral silk fibroin salt mixture. The degummed silk fiber is placed in the neutral silk fibroin protein salt mixture, aft...

Embodiment 3

[0034] Prepare aloe and cactus leaf extract respectively by the method for embodiment 1 and 2, be dispersed in deionized water, preparation 300ml volume percentage is the aloe leaf extract aqueous solution of 20% and 200ml volume percentage is the cactus leaf extract aqueous solution of 40%, After blending them, add 7ml of an amino-terminated hyperbranched compound aqueous solution with a concentration of 0.5wt%, and mix well to obtain a composite solution. After freezing for 5 hours at -20°C, thaw at room temperature for 6 hours, and cycle freeze-thaw for 3 times. , using NaOH solution to adjust its pH value to 11 to obtain a uniform and stable plant leaf extract dispersion.

[0035] Prepare 750ml of calcium chloride solution with a concentration of 30wt%, and mix it with 15ml of a sericin solution with a concentration of 1.5wt% to obtain a neutral sericin salt mixture, then take 10g of undegummed silk products and place them in neutral sericin salt In the mixed solution, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com