Surface passivation treatment method of martensite antibacterial stainless steel for surgical operating instrument

An antibacterial stainless steel, passivation treatment technology, applied in the direction of metal material coating process, etc., can solve the problems of affecting performance, hindering copper diffusion, antibacterial performance decline, etc., to achieve wide use, long-term antibacterial function, and improve corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

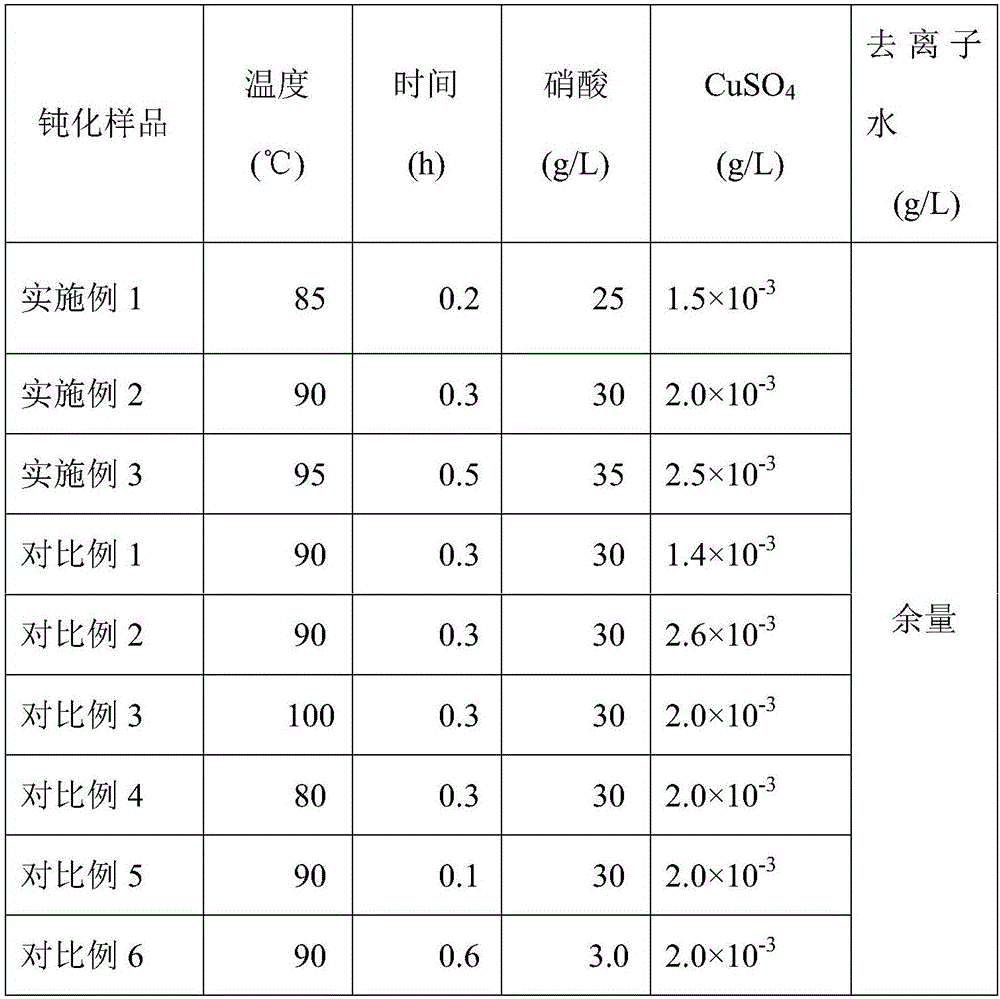

Embodiment 1

[0018] This specific embodiment adopts the following technical scheme: the surface passivation treatment method of martensitic antibacterial stainless steel for surgical instruments is as follows: put the antibacterial stainless steel surgical instruments into the passivation solution, and set the passivation treatment temperature to 85°C. The passivation time is 0.2h, and then washed with water, that is, the whole passivation process ends.

[0019] The proportioning ratio of the passivation solution is calculated by weight percentage: anhydrous copper sulfate: 1.5 × 10 -3 g / L; nitric acid: 25g / L; deionized water: supplementary amount g / L.

Embodiment 2

[0021] This specific embodiment adopts the following technical scheme: the surface passivation treatment method of martensitic antibacterial stainless steel for surgical instruments is as follows: put the antibacterial stainless steel surgical instruments into the passivation solution, and set the passivation treatment temperature to 90°C. The passivation time is 0.3h, and then washed with water, that is, the whole passivation process ends.

[0022] The proportioning ratio of the passivation solution is calculated as: anhydrous copper sulfate: 2.0×10 -3 g / L; nitric acid: 30g / L; deionized water: supplementary amount g / L.

Embodiment 3

[0024] This specific embodiment adopts the following technical scheme: the surface passivation treatment method of martensitic antibacterial stainless steel for surgical instruments is as follows: put the antibacterial stainless steel surgical instruments into the passivation solution, and set the passivation treatment temperature to 95°C. The passivation time is 0.5h, and then washed with water, that is, the whole passivation process ends.

[0025] The proportioning ratio of the passivation solution is calculated as: anhydrous copper sulfate: 2.5 × 10 -3 g / L; nitric acid: 35g / L; deionized water: supplementary amount g / L.

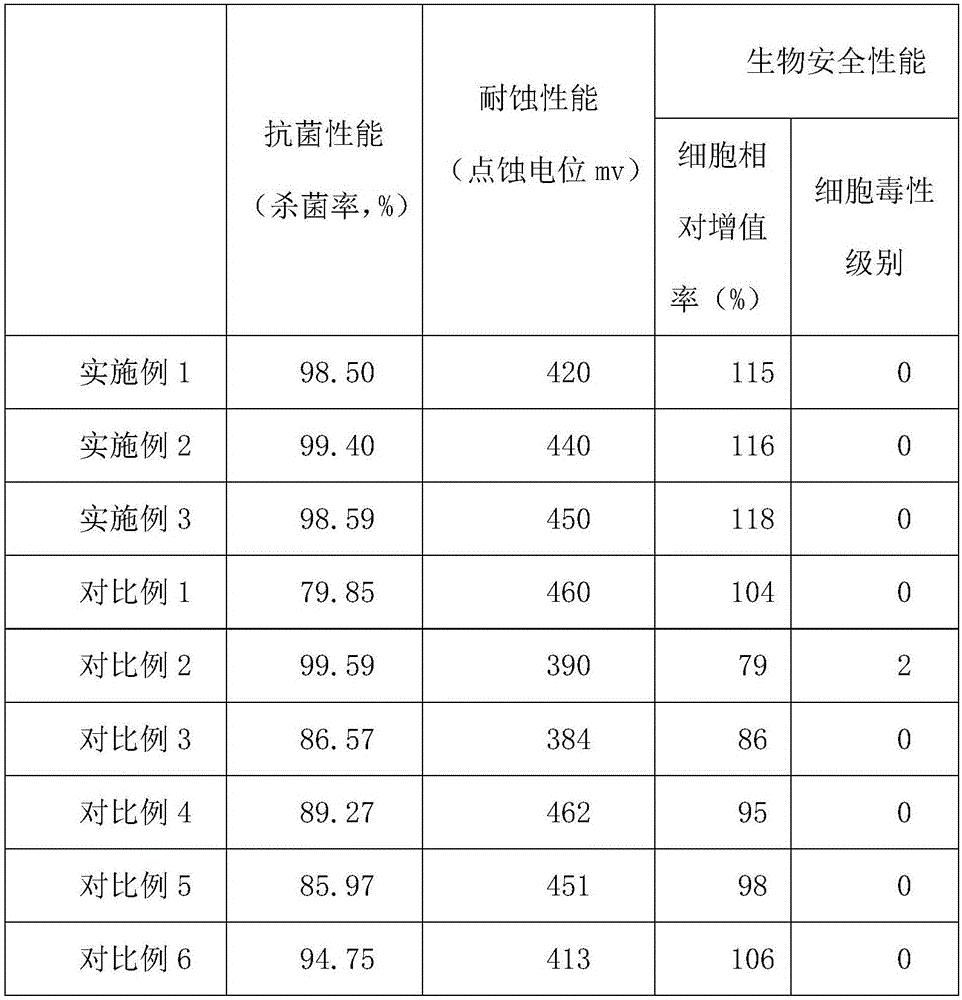

[0026] The passivation film component formed by the passivation treatment method of the present invention contains oxides of Cu and Cr, wherein the existence of the oxides of Cr can ensure effective corrosion resistance, when the material after passivation treatment is in contact with the solution medium, Copper-rich oxides can partially dissolve and relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com