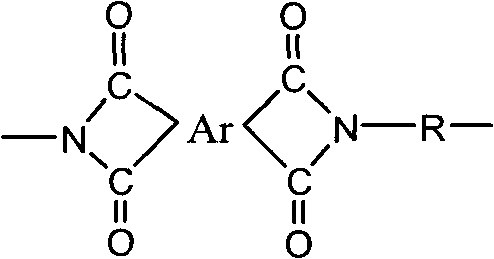

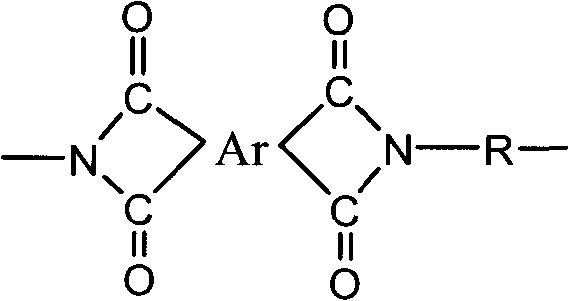

Colorless and transparent polyimide nano-composite material membrane and preparation method thereof

A technology of nanocomposite materials and composite material films, which is applied in the field of polymer-based nanocomposite materials, and can solve the problems of reduced transparency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

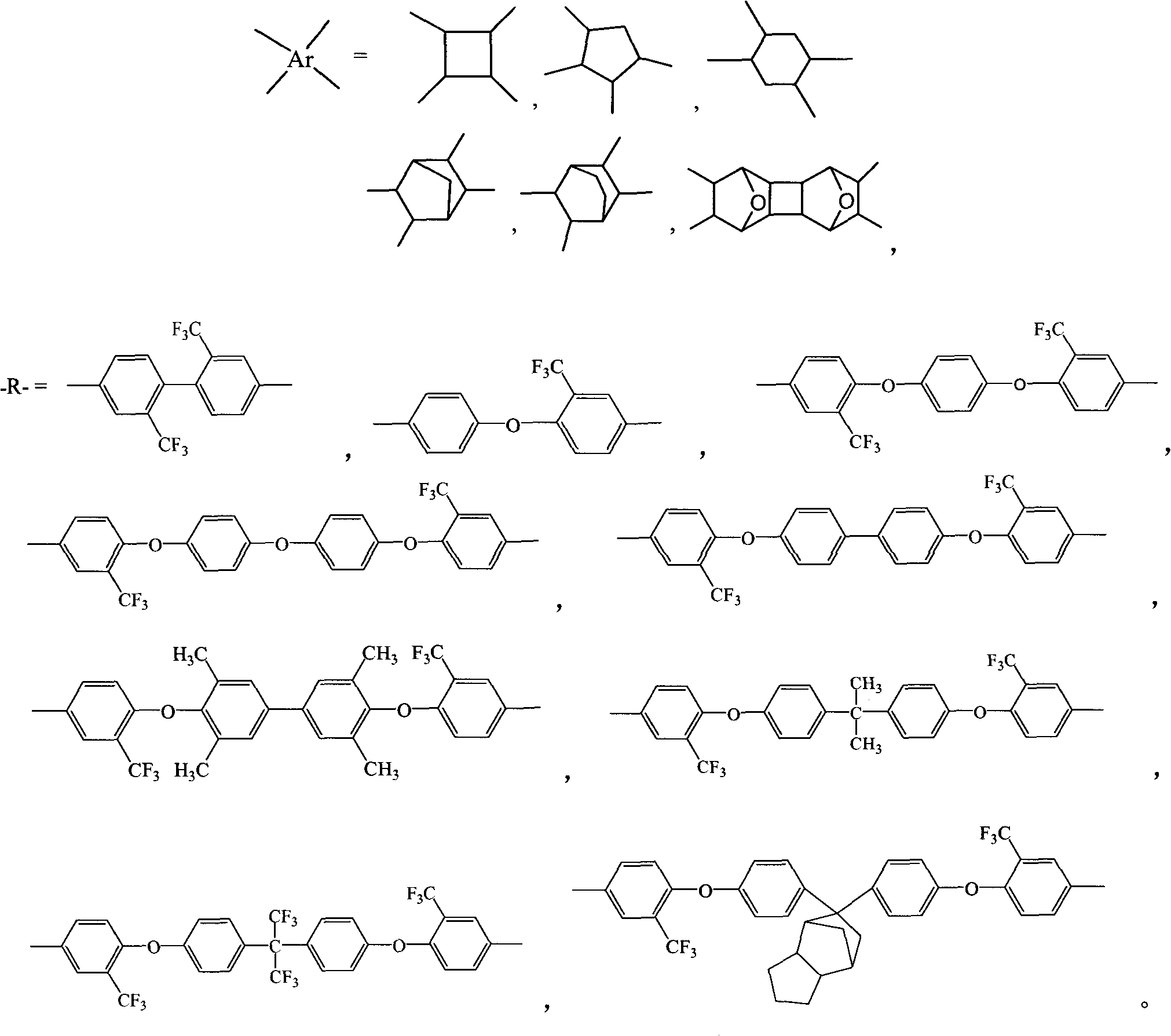

Method used

Image

Examples

Embodiment 1

[0043] Quaternary ammonium salt (CTAB) was used as an intercalant to perform ion exchange modification treatment on montmorillonite to prepare organic montmorillonite. 0.0427 g of organic montmorillonite was added to 6.38 ml of N,N-dimethylacetamide (DMAc) solvent, and dispersed at 80° C. under strong mechanical stirring for 5 hours to obtain a DMAc solution of organic montmorillonite. In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 6.5445 g of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane (0.01mol) dissolved in 45ml DMAc solvent, stirred to make the solution clear and transparent. Then add 1.9611g (0.01mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA) to the solution at one time, stir to dissolve it completely, and continue to react for 15-25 under a nitrogen atmosphere. Within hours, a transparent viscous liquid-polyamic acid (PAA) solution was obtained. The DMAc solution of the above-mentioned...

Embodiment 2

[0046] Will 0.0645g warp? -Aminopropyltriethoxysilane treated nano zinc oxide (particle size 30nm) was dispersed in 27.23ml of DMAc solvent under ultrasonic action, a uniform mixed solution was obtained after 2 hours, and moved to equipped with a stirrer and thermometer And nitrogen gas into the three-necked reaction flask. Dissolve 4.2833 g (0.01 mol) of 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene in the above solution, and stir to make the solution clear and transparent. Then add 2.1014g (0.01mol) of 1,2,4,5-cyclopentanetetracarboxylic dianhydride (CPDA) to the solution at once, stir to dissolve it completely, and continue to react for 15-25 under a nitrogen atmosphere. After hours, a transparent viscous liquid-polyamic acid solution with a solid content of 20 wt% by weight is obtained, and the intrinsic viscosity is 1.15 dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a dry box with nitrogen protection, and increase the temperature according ...

Embodiment 3

[0049] In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 6.5445 g of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane (0.01mol) was dissolved in 53.08ml of DMAc solvent and stirred to make the solution clear and transparent. Then add 2.2417g (0.01mol) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride (CHDA) to the solution at once, stir to dissolve it completely, and continue to react for 15-25 under a nitrogen atmosphere. After hours, a transparent viscous liquid-polyamic acid solution with a solid content of 15 wt% by weight is obtained, and the intrinsic viscosity is 1.00 dL / g. Add 0.1529 g of tetraethyl orthosilicate (TEOS) and a little water to the polyamic acid solution. After stirring for 20 hours, the mixed solution is coated on a clean glass plate and placed in a dry box protected by nitrogen. The temperature is increased according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com