Preparation method of polyinosinic-polycytidylic acid dry powder

A technology of double-chain polymyocytes and dry powder, which is applied in the field of preparation of double-chain polymyocyte dry powder, can solve the problems of increasing the difficulty of monitoring, increasing the steps of polymerization reaction, and increasing the complexity of operation, so as to achieve increased stability and enhanced curative effect , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

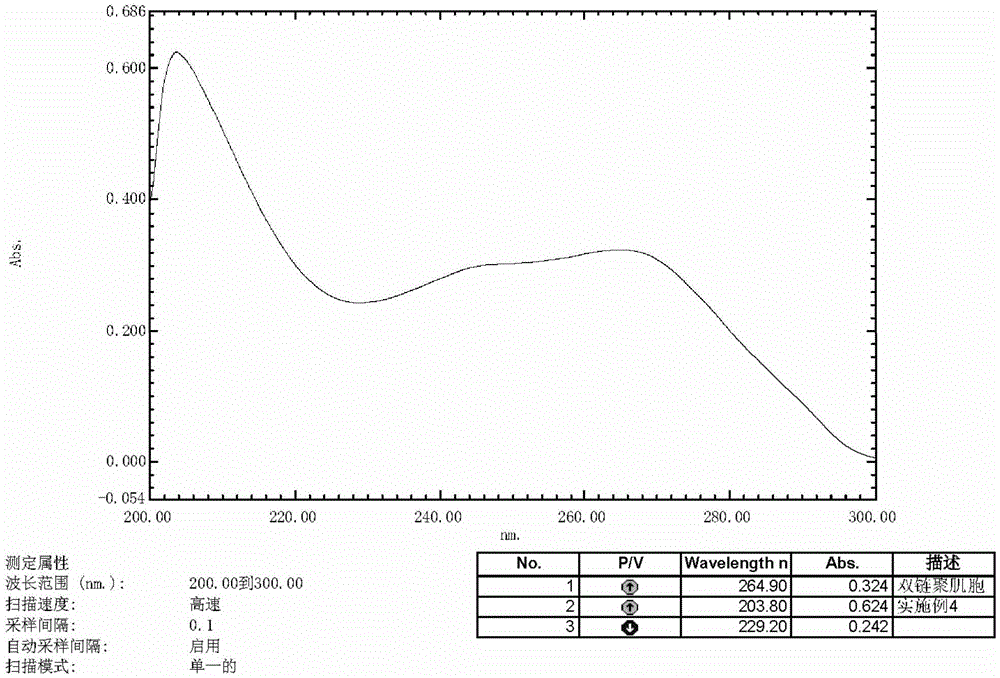

Image

Examples

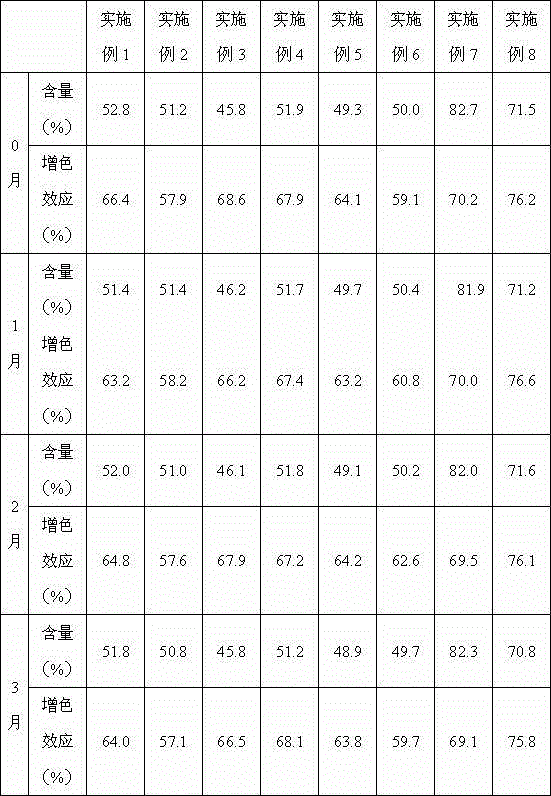

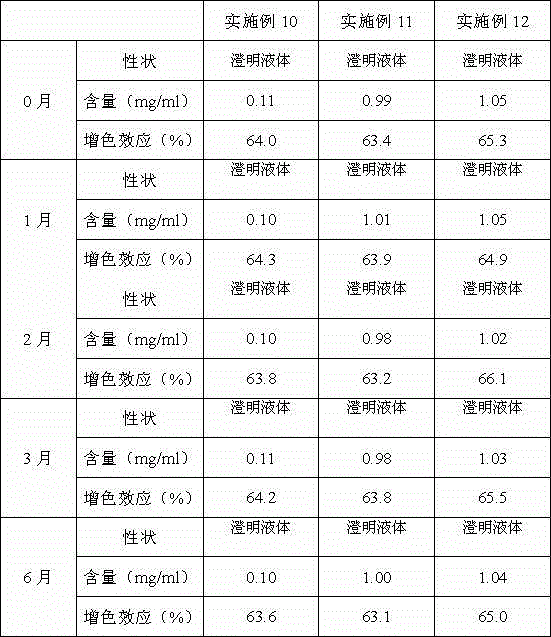

Embodiment 1

[0034]Weigh 5.2g of polyinosinic acid and 5.5g of polycytidylic acid and dissolve them in 100mL of phosphate buffer (pH6.4) and mix them, add 10.7g of chitosan oligosaccharide and mix evenly, keep warm at 60°C for 60min, cool naturally, and then Precipitate with 400mL of ethanol for 2 hours to obtain the polyinocytic precipitate, and dry at 20°C to obtain the double-chain polyinogenic dry powder (the content of the double-chain polyinocytic is 52.8%).

[0035] The color enhancement effect of the mixed solution and dry powder at 248nm was detected respectively, and the results are as follows: the color enhancement effect of the solution is 56.4%, and the color enhancement effect of the dry powder is 66.4%.

Embodiment 2

[0037] Weigh 3.5g of polyinosinic acid and 5.2g of polycytidylic acid (1:1.5) each dissolved in 100mL phosphate buffer (pH7.2) and mix them, add 8.7g of kanamycin and mix well, keep warm at 80°C for 60min , after natural cooling, then precipitated with 400mL of ethanol for 12 hours to obtain a polysarcoma precipitate, and dried at 35°C to obtain a double-stranded polysarcoma dry powder (the content of which is 51.2%).

[0038] The color enhancement effect of the mixed solution and dry powder at 248nm was detected respectively, and the results are as follows: the color enhancement effect of the solution is 55.3%, and the color enhancement effect of the dry powder is 57.9%.

Embodiment 3

[0040] Weigh 5.4g of polyinosinic acid and 5.1g of polycytidylic acid and dissolve them in 100mL of phosphate buffer (pH7.5), mix them, add 10.5g of kanamycin and 1.5g of calcium chloride, mix well, and keep warm at 60°C After cooling for 60 minutes, 400 mL of methanol was used to precipitate for 24 hours to obtain a polysarcoma precipitate, which was dried at 60°C to obtain a double-stranded polysarcoma dry powder (the content of which was 45.8%).

[0041] The color enhancement effect of the mixed solution and dry powder at 248nm was detected respectively, and the results are as follows: the color enhancement effect of the solution is 65.5%, and the color enhancement effect of the dry powder is 68.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com