Method for continuously cleaning and passivating copper and copper alloy

A copper alloy and passivation solution technology, applied in the direction of metal material coating process, can solve the problems of passivation solution pollution, affect the effect of passivation, discoloration, etc., and achieve the effects of less environmental pollution, slowing down the reaction, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

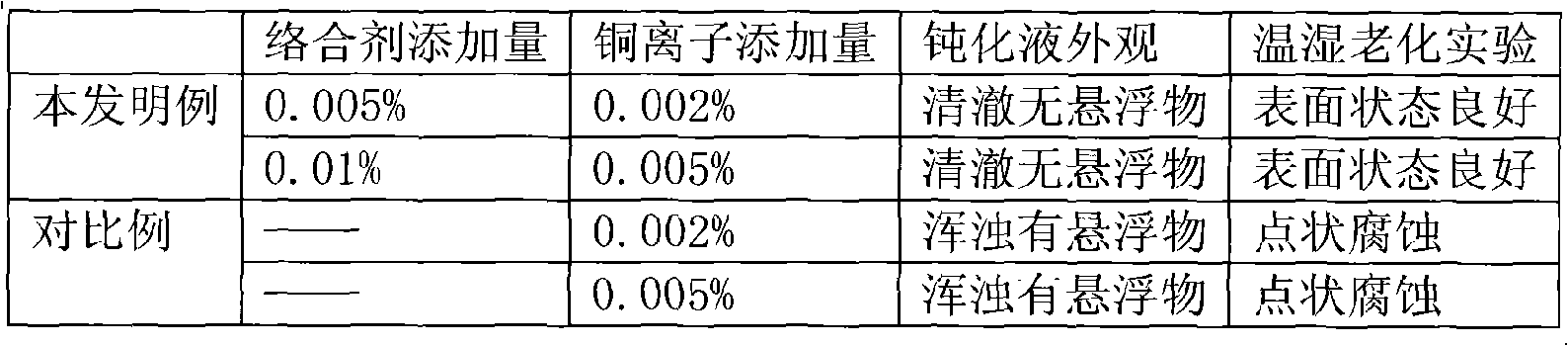

Embodiment 1

[0026] The red copper strip with a thickness of 0.15mm and a width of 450mm is placed on the continuous processing line and then undergoes brushing and degreasing; cold water washing; pickling; cold water brushing; hot water washing; passivation treatment; % Henkel degreasing powder aqueous solution, the degreasing temperature is 80°C, the pickling solution is 10% sulfuric acid aqueous solution, the pickling condition is normal temperature, the passivation solution is 0.2% benzotriazole aqueous solution, and then 0.005% by weight of the passivation solution or 0.01% by weight of the passivation solution is added with tartaric acid, and the passivation temperature is 70°C. (The passivation solution may contain benzotriazole, benzotriazole derivatives or both).

[0027] In this embodiment, the main substance brought into the passivation solution in the previous process is copper ions, which are brought in in the form of copper sulfate, to simulate the actual production process, ...

Embodiment 2

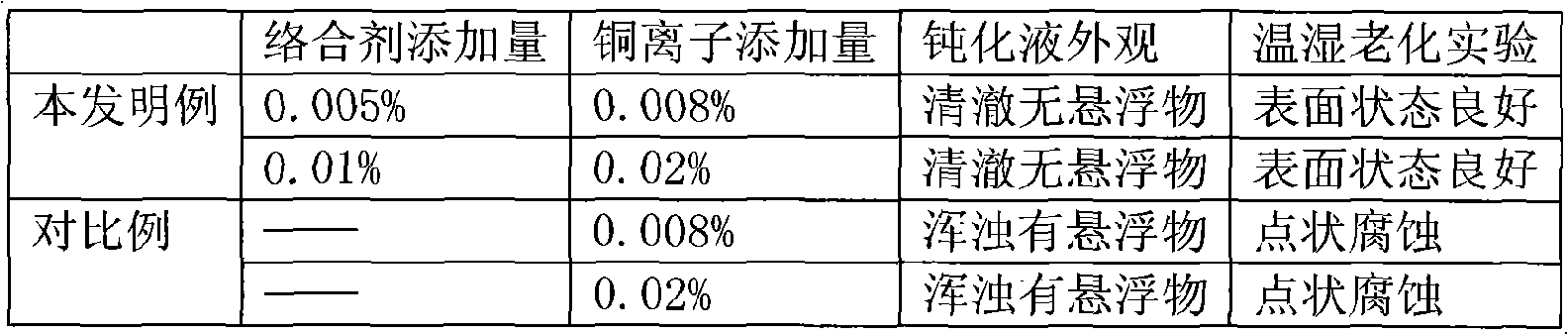

[0039] The type of complexing agent selected: lactic acid; the passivation solution adopts hydroxybenzotriazole with a concentration of 0.3%, and other steps and conditions are the same as in Example 1, and the final results are shown in Table 2.

[0040] Copper strip surface quality observation method: visual method.

[0041] Greenhouse aging test method: 60℃×95%RH×7days

[0042] Cu 2+ Addition amount: 0.002%, 0.005% (added in the form of copper sulfate)

[0043] After continuous operation of the continuous processing line for 2 days, sampling observation experiment

[0044] Table 2

[0045]

[0046] Table 2 shows: after adding copper ion complexing agent lactic acid in the passivation solution, the pollution degree of the passivation solution is small, and the surface state of the copper strip is good.

Embodiment 3

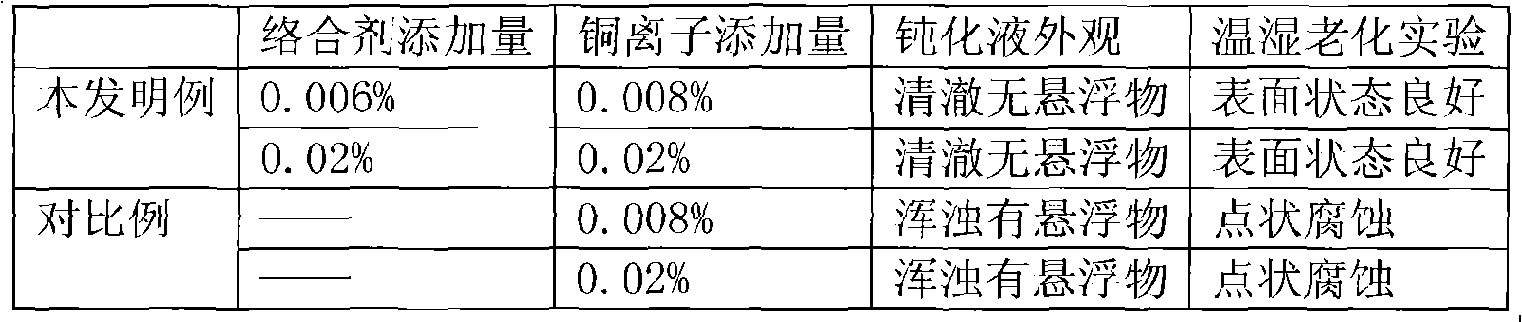

[0048] Complexing agent selection type: sodium citrate, other steps and conditions are the same as in Example 1, and the final results are shown in Table 3.

[0049] table 3

[0050]

[0051] Table 3 shows: after adding the copper ion complexing agent lactic acid in the passivation solution, the pollution degree of the passivation solution is small, and the surface state of the copper strip is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com