Water/oxygen barrier polymer-based composite material as well as preparation method and application thereof

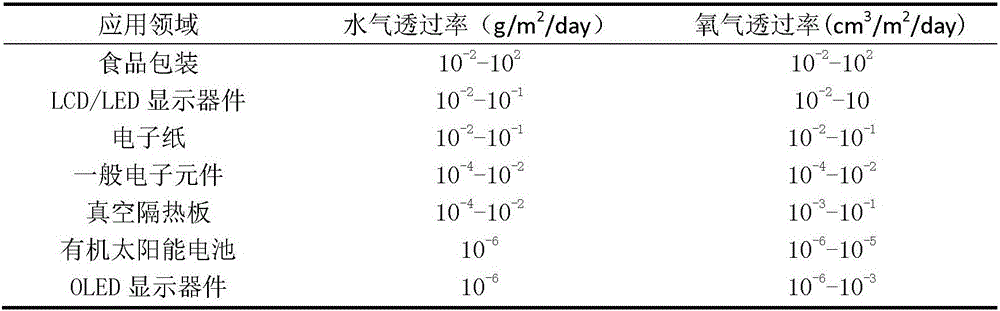

A technology of oxygen barrier polymers and composite materials, which is applied in the field of flexible electronics and display devices, can solve the problems of complex process, difficulty in large-scale application, and high cost, and achieve the effects of low preparation cost, wide application range, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

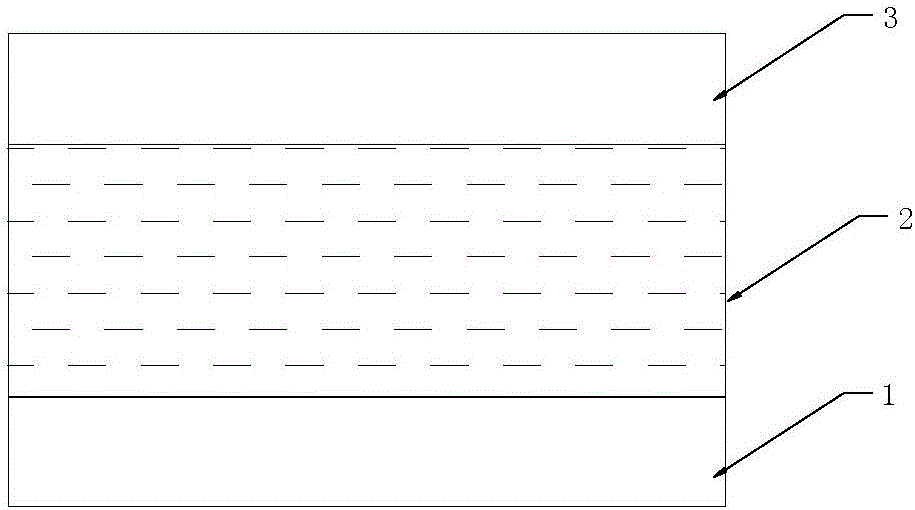

[0042] This example is a preparation example of a water / oxygen barrier polymer-based composite film material.

[0043] The water / oxygen barrier polymer matrix composite film material is prepared according to the following steps:

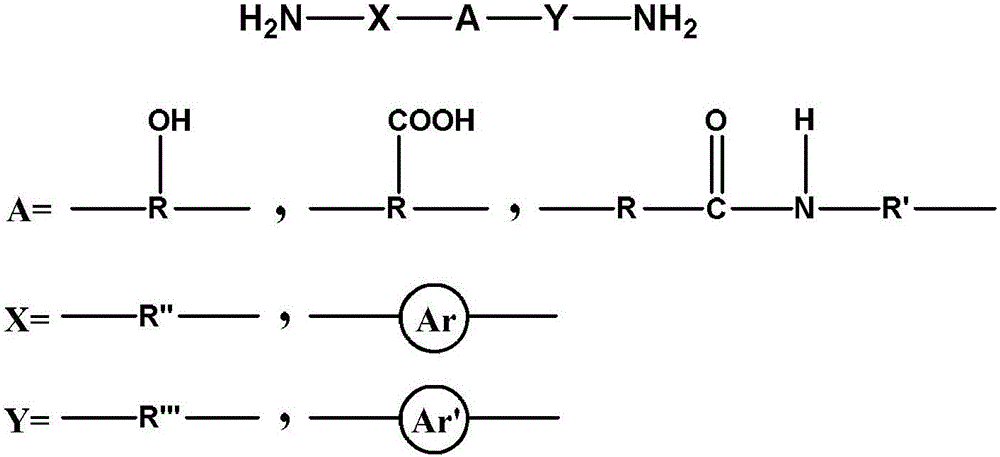

[0044] 1. Prepare the prepolymer of the upper layer and the lower polymer surface layer: get 0.8049g (4.02mmol) of diamine monomer diaminodiphenyl ether ODA and add it in 10mL DMF solution, and continue to stir for a period of time to make the system fully mixed; In the above system, add 0.8943 g (4.10 mmol) of dianhydride monomer 1,2,4,5-pyromellitic dianhydride PMDA was added and stirred at a moderate speed for 6 hours until the system formed a sol.

[0045] 2. Modification and intercalation of inorganic layered fillers: take 10 g of sodium-based montmorillonite and 100 mL of ultrapure water to make a 5%-10% suspension under the condition of ultrasonic stirring. The upper suspension was centrifuged to obtain montmorillonite with smaller particle s...

Embodiment 2

[0055] This example is a preparation example of a water / oxygen barrier polymer-based composite film material.

[0056] The water / oxygen barrier polymer matrix composite film material is prepared according to the following steps:

[0057] 1. Prepare the prepolymer of the upper and lower polymer surface layers: take 1.0248g (4.74mmol) of diamine monomer 4,4'-diaminodiphenyl sulfide SDA and add it to 10mL of DMF solution, and continue stirring for a period of time to make the system fully Mix; add 1.0540 g (4.83 mmol) of dianhydride monomer 1,2,4,5-pyromellitic dianhydride PMDA to the above system, and stir at moderate speed for 6 hours after adding until the system forms a sol.

[0058] 2. Modification and intercalation of inorganic layered fillers: take 10 g of sodium-based montmorillonite and 100 mL of ultrapure water to make a 5%-10% suspension under the condition of ultrasonic stirring. The upper suspension was centrifuged to obtain montmorillonite with smaller particle siz...

Embodiment 3

[0068] This example is a preparation example of a water / oxygen barrier polymer-based composite film material.

[0069] The water / oxygen barrier polymer matrix composite film material is prepared according to the following steps:

[0070] 1. Prepare the prepolymer of the upper and lower polymer surface layers: take 1.3841 g (3.28 mmol) of the diamine monomer 2,2'-bis(4-aminophenoxyphenyl) propane BAPP and add it to 10 mL of DMF solution, continue Stir for a period of time to make the system fully mixed; add 0.7307g (3.35mmol) of dianhydride monomer 1,2,4,5-pyromellitic dianhydride PMDA to the above system, and stir at a medium speed for 6 hours after adding until the system forms sol.

[0071] 2. Modification and intercalation of inorganic layered fillers: take 10 g of sodium-based montmorillonite and 100 mL of ultrapure water to make a 5%-10% suspension under the condition of ultrasonic stirring. The upper suspension was centrifuged to obtain montmorillonite with smaller par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com