Preparation method of solar cell assembly and prepared solar cell assembly by utilizing preparation method

A kind of technology of solar cell module and battery pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

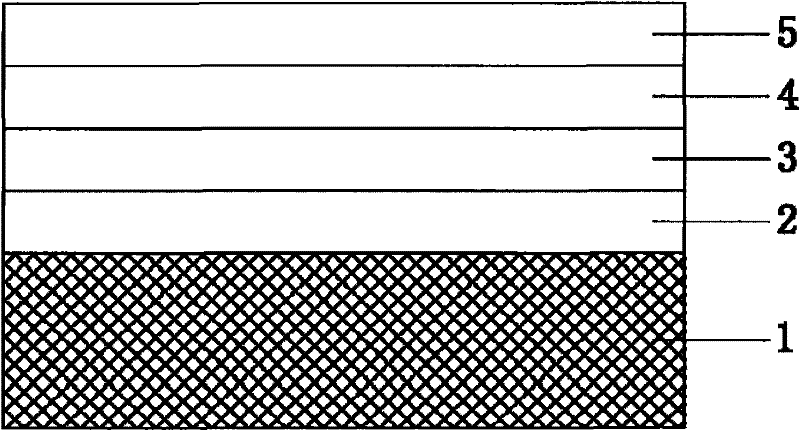

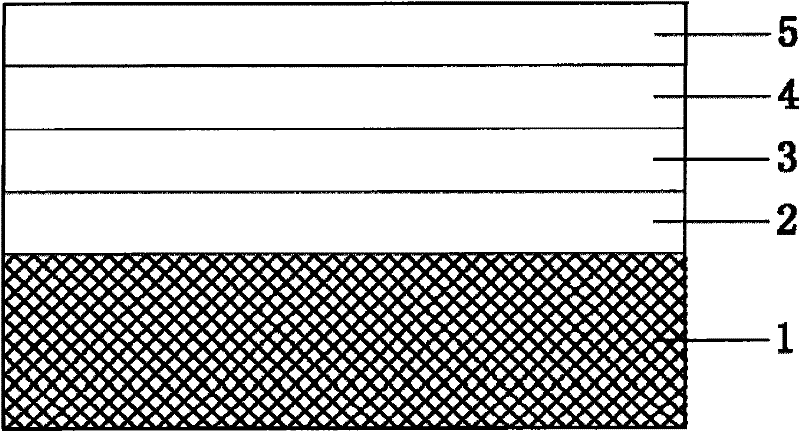

[0022] The preparation method of the solar cell assembly of the present embodiment comprises the following steps:

[0023] 1) Lay the backplane, the first layer of packaging film, the solar battery strings, the second layer of packaging film and the panel film in sequence. The backplane is FRP film with a thickness of 3.2mm; the first layer of packaging Both the adhesive film and the second packaging adhesive film are made of EVA film with a thickness of 0.5mm; the panel adhesive film can be ETFE film or FEP film with a thickness of 0.1mm;

[0024] 2) Set a layer of tetrafluoro cloth on the above-mentioned panel adhesive film, and the tetrafluoro cloth is the tetrafluoro cloth manufactured by Saint-Gobain in the market, whose model is CF1688;

[0025] 3) Laminate the above laminated layers in a laminator, wherein the temperature during lamination is 140-145°C; the vacuuming time is 10-15min; the lamination pressure is 800kPa; the lamination holding time is 20- 25 minutes; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com