Release film for semiconductor resin molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

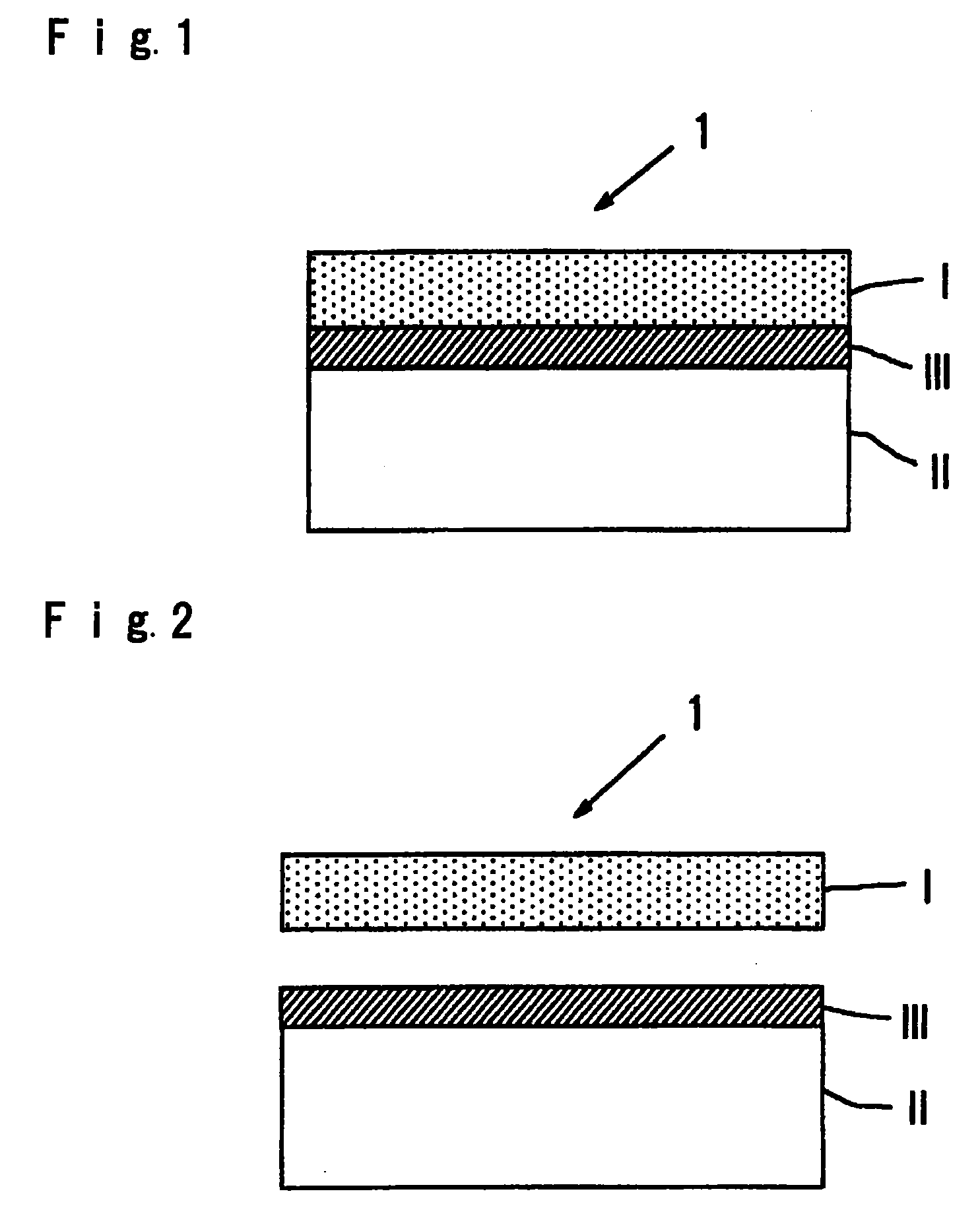

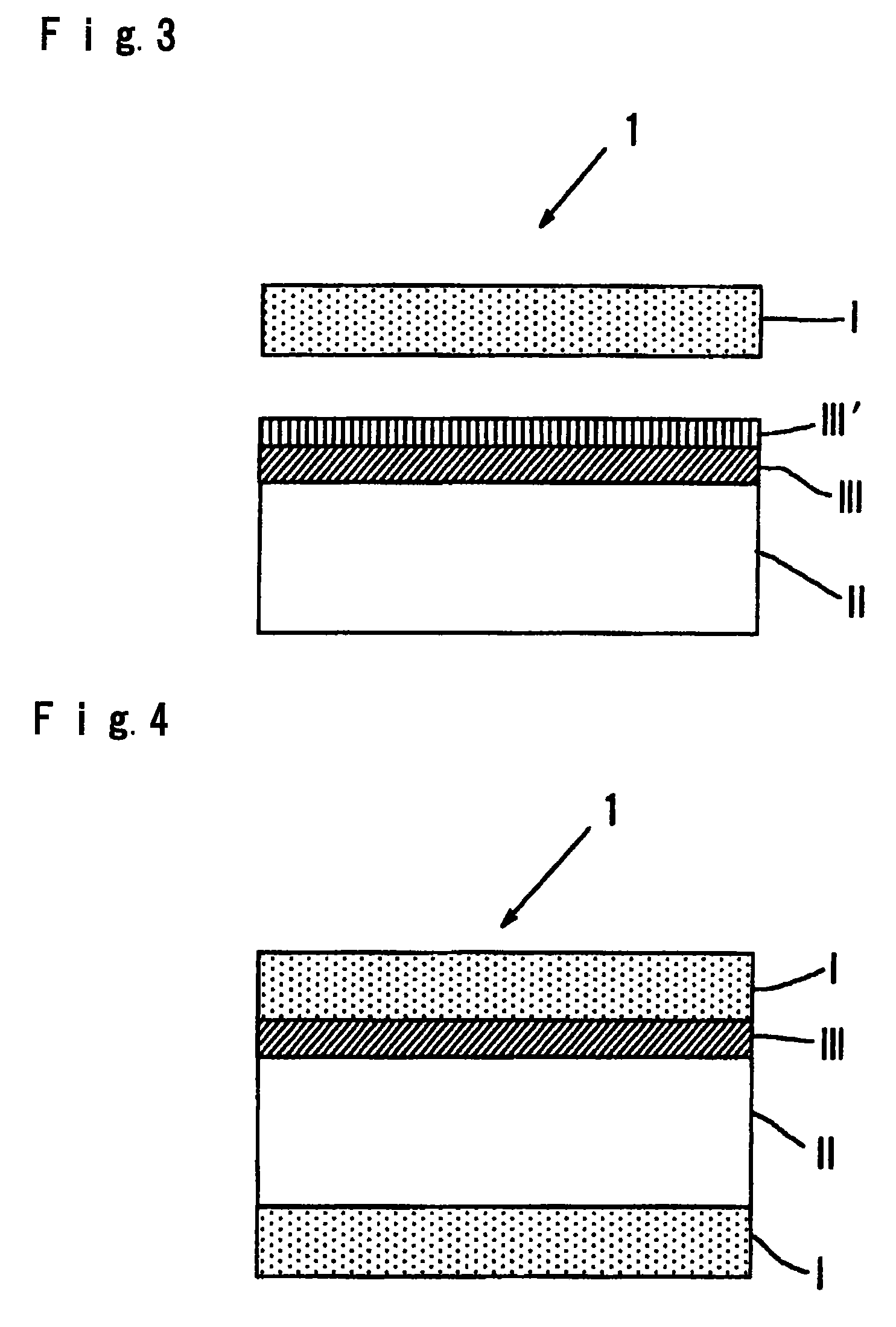

[0075](1) As the release layer (I), an ETFE film (manufactured by Asahi Glass Company, Limited, tradename: FLUON ETFE) having a thickness of 12 μm was used. One side (surface (surface to be bonded) facing a support layer) of the ETFE film was treated by corona discharge-treatment with a discharge amount of 40 W·min / m2 to improve the adhesion.

[0076]Further, a 12 μm polyethylene terephthalate film was used as the plastic support layer (II), and on one side of it, alumina was vapor-deposited as a metal oxide to form a gas restraint layer (III). Further, on it, a resin protection layer (III′) was coated to form a film (manufactured by Toppan Printing Co., Ltd., tradename, GX Film).

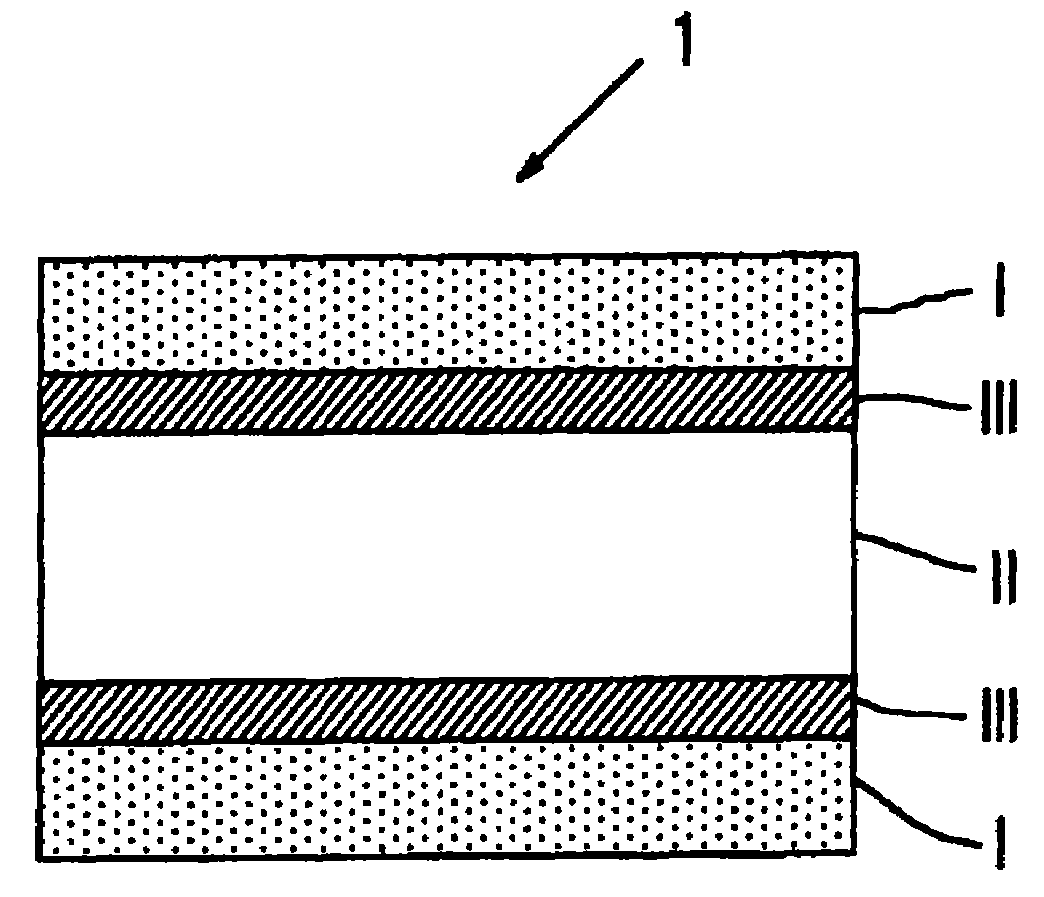

[0077](2) On the surface of the resin protection layer (III′) of the above film (GX Film), a polyester adhesive was applied to have a film thickness of 0.4 μm as dried, followed by drying, and as shown in FIG. 3, dry-laminating with a release layer (I) was carried out to obtain a release film (hereinafter refe...

example 2

[0084](1) A release film (hereinafter referred to as “release film 3”) was obtained in the same manner as in Example 1 except that a 12 μmethylene / vinyl alcohol copolymer (manufactured by Kuraray Co., Ltd., tradename: EVAL EF-F) was used as the plastic support layer (II), and on its one side, aluminum was sputtered in a thickness of 10 nm to form a gas restraint layer (III), and no resin protection layer (III′) was formed.

[0085](2) With respect to the release film 3, the xylene gas permeability coefficient in an environment at 170° C. was calculated in the same manner as in Examples. Further, the peel strength was measured by a 180° C. peel test in the same manner as in Example 1.

[0086]The xylene gas permeability coefficient of the release film 3 was 1×10−16 (kmol·m / (s·m2·kPa)), the peel strength by a 180° peel test was 0 (N / m). The result is shown in Table 1.

[0087](3) Further, in the same manner as in Example 1, a mold shot was repeatedly carried out by using the release film 3, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com