Manufacturing method for flexible solar cell unit

A technology for solar cells and components, applied in the field of solar cells, can solve the problems of inability to carry, cannot move, and the battery is bulky, and achieves the effects of being light and easy to carry, simple and easy to operate, and simplified in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

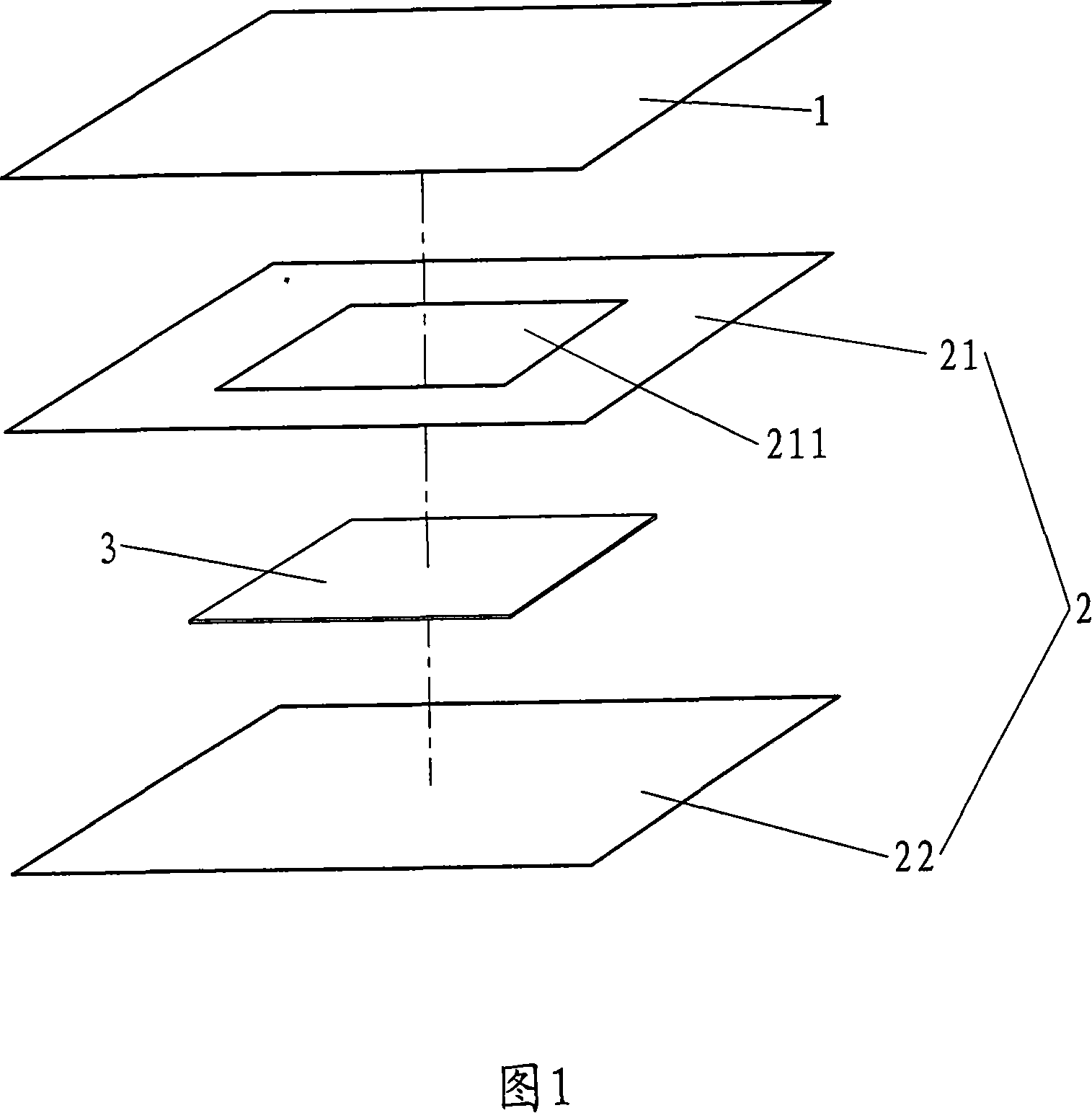

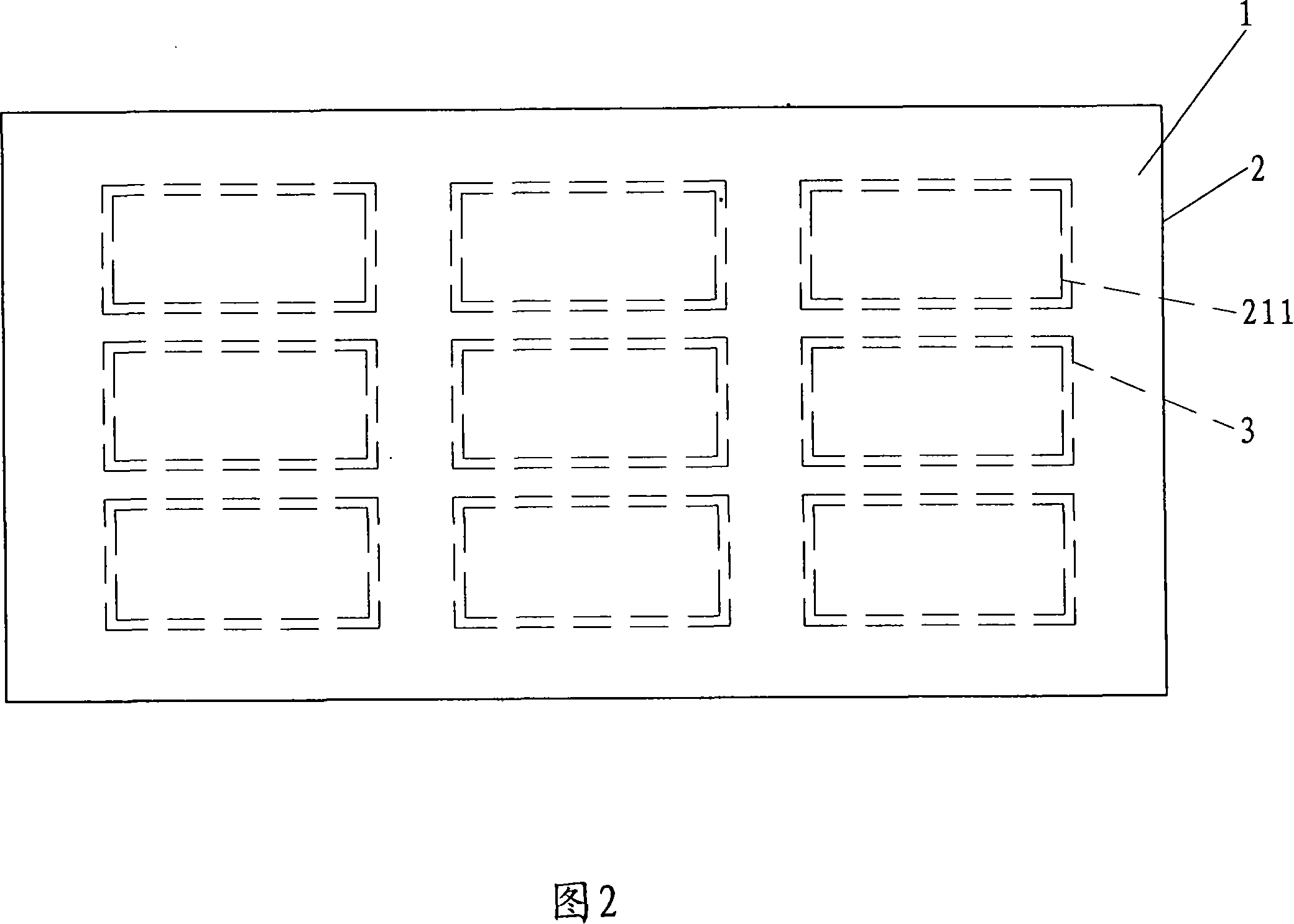

[0025] As shown in Figures 1 and 2, a method for preparing a flexible solar cell module of the present invention, the specific steps are:

[0026] 1), first spread the polymer film 1; the polymer film is an ethylene-polytetrafluoroethylene (ETFE) protective film with good light transmission.

[0027] 2) Next, cut the cloth base 2 into required specifications and place it flat on the polymer film 1; the cloth is polyester, nylon, acrylic, vinylon, cotton, viscose, hemp, flax, ramie, silk or more fibers One of blended fabrics and non-woven fabrics.

[0028] 3), put the unit solar cell chip 3 into the cloth base 2, the cloth base 2 is the upper cloth base 21, and the part of the upper cloth base 21 corresponding to the light-receiving part of the unit solar cell chip 3 is cut out to leave the hole 211 for the purpose of After packaging, the light-receiving part of the unit solar cell chip 3 is not covered; use a laminator for low-temperature hot-pressing and fixing; the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com