Separation apparatus and method of high precision rectification purify trichlorosilane

A technology for purifying trichlorosilane and separating devices, applied in fractionation, halide silicon compounds, etc., can solve the problems of increased equipment investment, low separation efficiency, backward technology, etc., and achieve good economic and social benefits, separation and purification efficiency Efficient and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way.

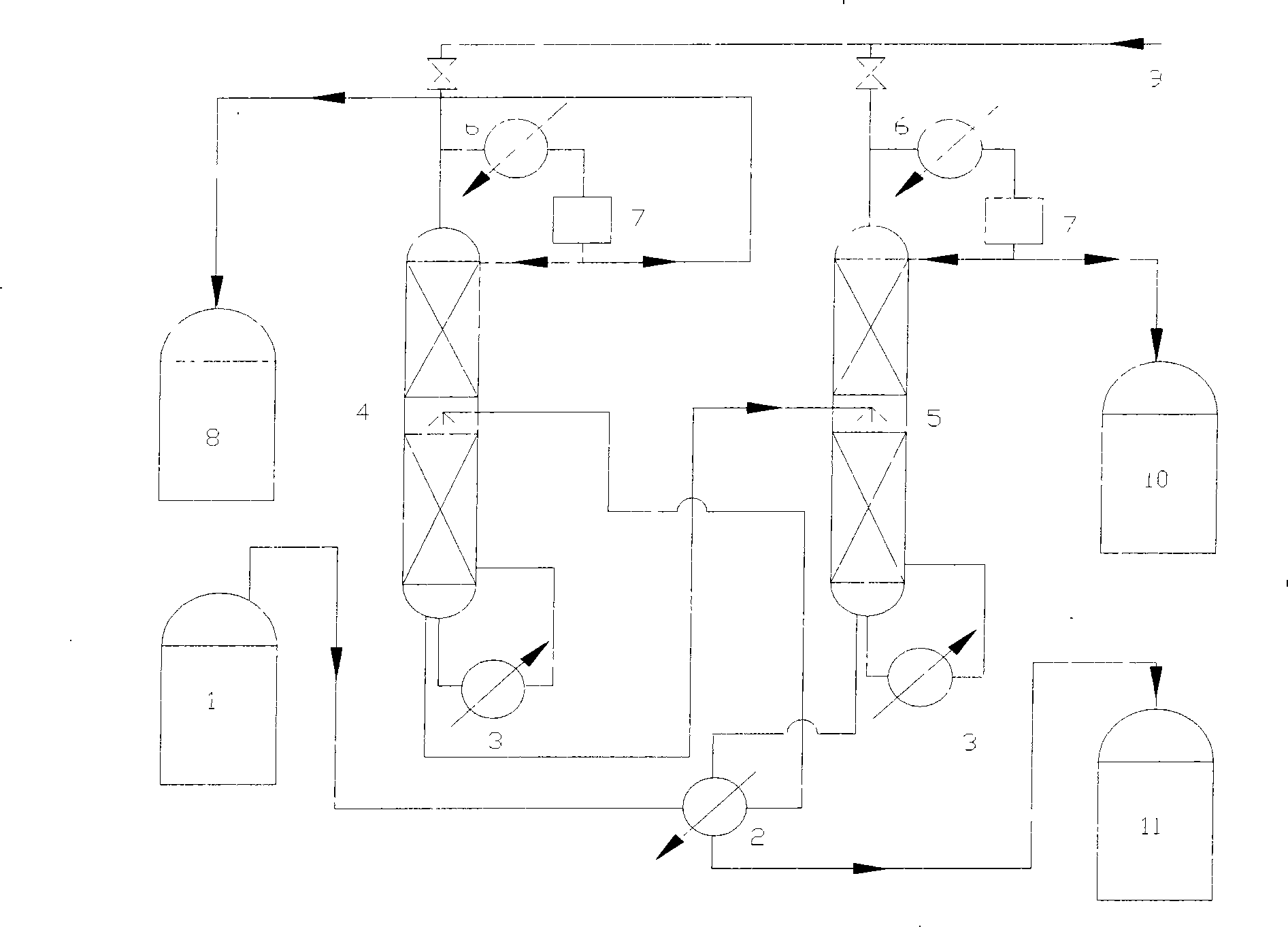

[0023] For the initial raw materials after synthesis of trichlorosilane provided by a domestic unit, use figure 1 The technical process and its equipment are studied on the high-precision rectification and purification of the pilot scale. The connection mode of the equipment is as follows: the trichlorosilane raw material liquid passes through the raw material storage tank 1 and first enters the low boiler separation tower 4 through the raw material preheater 2 In the middle, the top of the tower is condensed with a condenser 6, and the bottom of the tower uses a reboiler 3 to provide heating steam in the tower, while the top of the tower is fed with high-pressure hydrogen 9 to maintain the pressure of the system; The steam of the steam passes through the condenser 6 to the reflux tank 7, and a part of the condensate is refluxed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com