Silicon based micro passage heat exchanger

A technology of heat exchangers and microchannels, which is applied in the field of silicon-based microchannel heat exchangers, can solve problems such as the limitation of cooling and heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

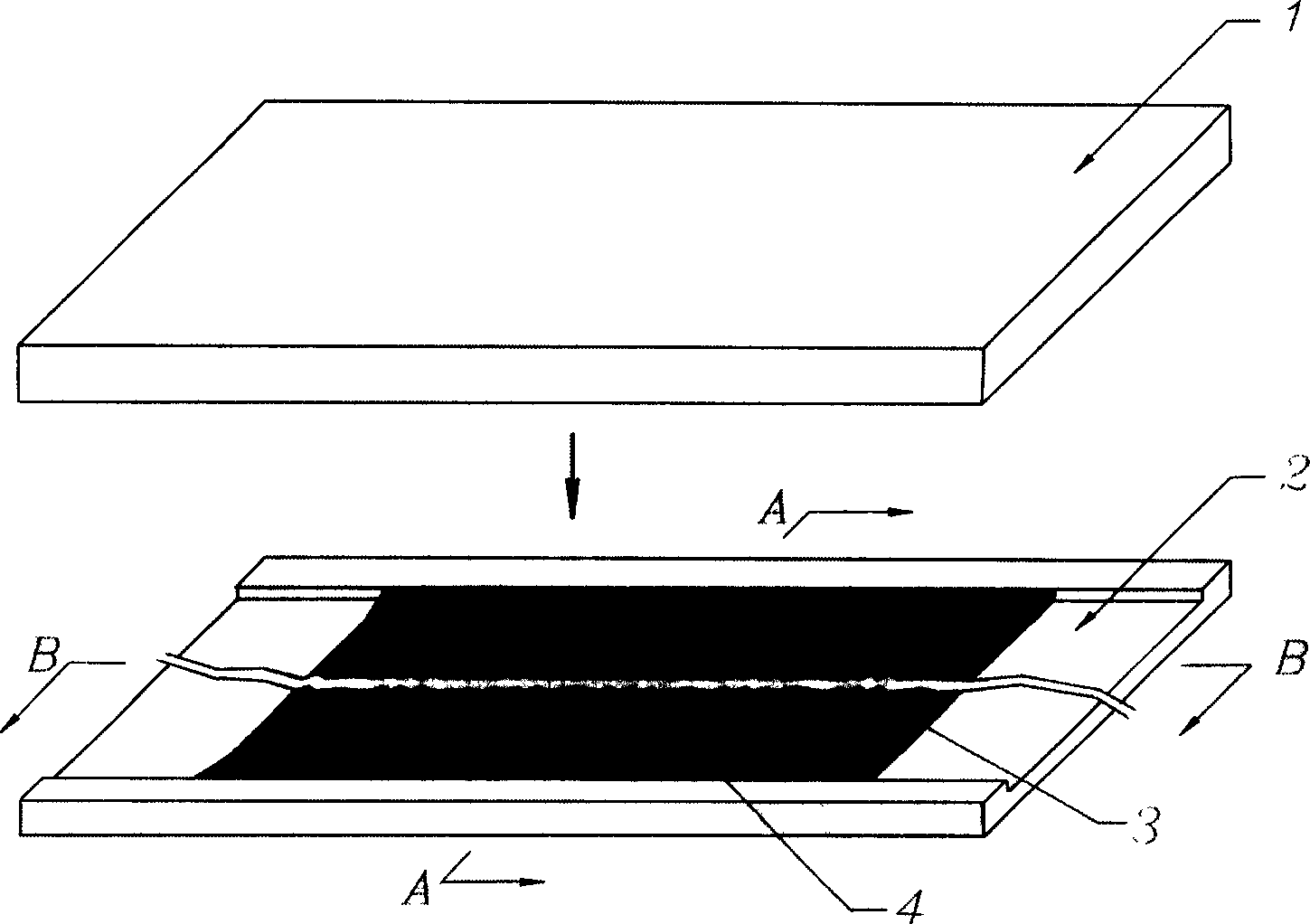

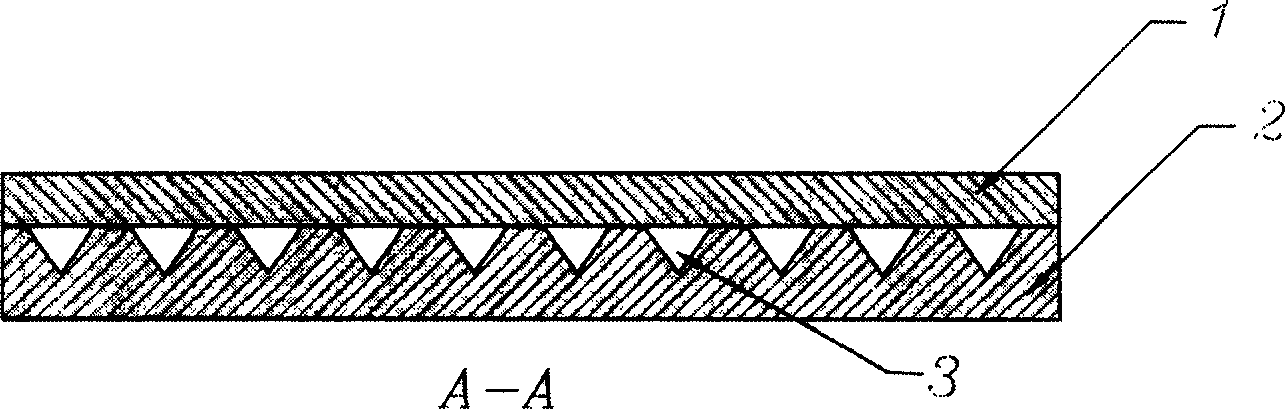

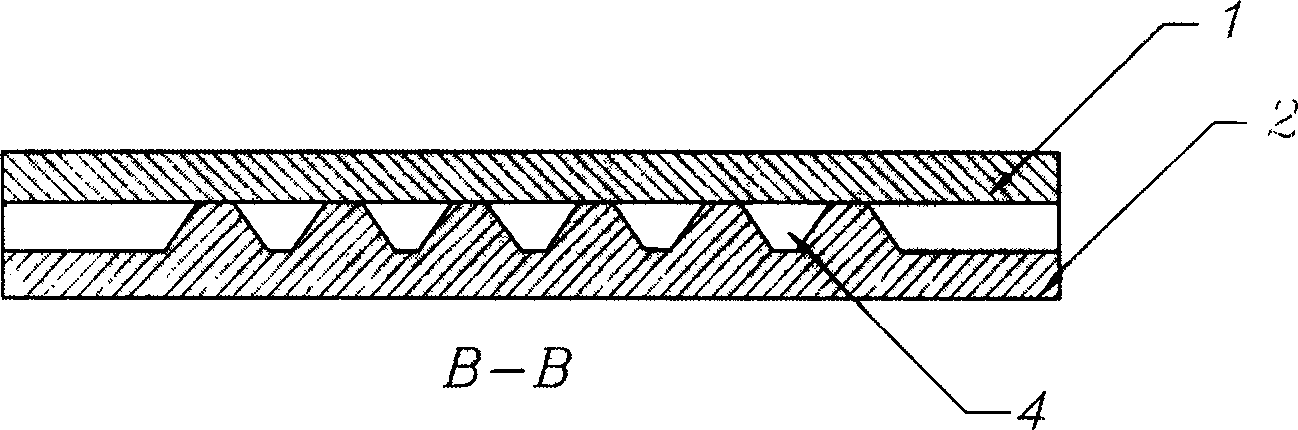

[0017] The structure of the silicon-based microchannel heat exchanger is as follows: Figure 1~3 As shown, a plurality of parallel longitudinal microchannels 3 are processed on the semiconductor silicon substrate 2 along the cooling liquid flow direction by etching process, and its hydraulic diameter D is 0.1mm. A transverse microchannel 4 is processed every 3 mm perpendicular to the flow direction, and its hydraulic diameter is 0.3 mm, forming a criss-cross microchannel array. After the micro-channel array is formed, the upper surface of the silicon wafer is bonded to the heat-resistant glass 1 by high-voltage electrostatic field bonding technology to package the micro-channel array, and the silicon-based micro-channel heat exchanger is manufactured.

[0018] The method of using the silicon-based microchannel heat exchanger as a cooling device for electronic components is as follows: Figure 5 As shown, the micropump 8, the connecting pipe 7 and the silicon-based microchanne...

Embodiment 2

[0021] This embodiment is an application example of integrating the silicon-based microchannel heat exchanger 5 of the present invention with other IC chips 6 , wherein the structure of the microchannel array in the silicon-based microchannel heat exchanger 5 is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com