Technology for continuously producing secbutyl acetate

A sec-butyl acetate and process technology, applied in the field of high-efficiency continuous production of sec-butyl acetate, can solve the problems of low raw material utilization rate, long reaction time, high production cost, etc., and achieve enhanced effective contact, uniform distribution, low production energy consumption and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

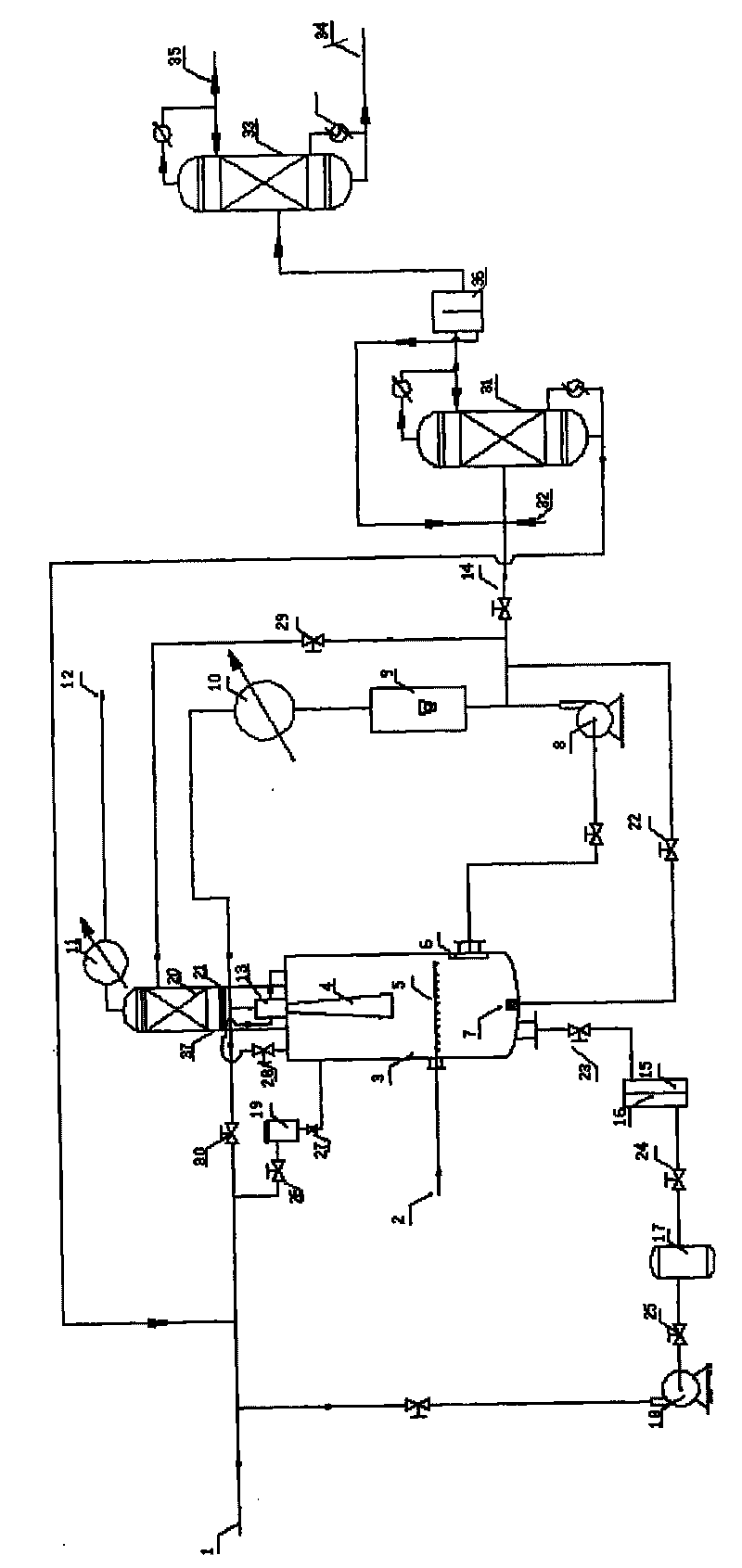

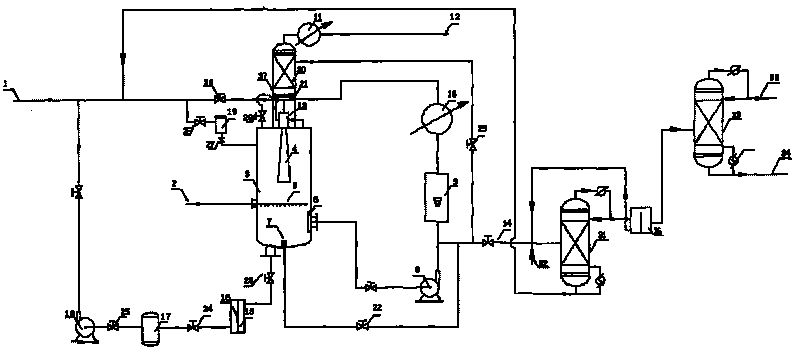

[0034] The process flow is shown in Figure 1, wherein the volume of the reaction section of the jet collision flow tower reactor 3 is 6m 3 , with a diameter of 1.6m and a height of 3.2m; the tray / packed column reaction section 20 has a diameter of 1.0m and a height of 6m, and the ejector is provided by Shuanghong Engineering Technology Development Co., Ltd.

[0035] Acetic acid and butene are 1: 1.1 by the ratio of substance amount, join after pipeline 1 and mix with solid-liquid mixed acid catalyst (catalyst amount accounts for 10% of acetic acid mass) in catalyst feeding device 19 and join jet collision flow tower In reactor 3, butene enters jet collision flow tower reactor 3 from pipeline 2 through gas distributor 5, the reaction temperature is 110°C, the pressure is 0.8MPa (gauge pressure), and the solid catalyst is Amberlyst 15 (U.S.A. Rohm and Haas company production), liquid catalyst is sulfuric acid, wherein liquid acid accounts for 20% (the amount of H+ that liquid ac...

Embodiment 2

[0037] Adopt the reaction equipment identical with embodiment 1, be similar to embodiment 1 operation method, the mol ratio of acetic acid and butene is 1: 1.2, 120 ℃ of reaction temperatures, the pressure of jet collision flow tower reactor 5 is 1.2MPa (table pressure), the catalyst used is a solid-liquid mixed acid catalyst (catalyst amount accounts for 7% of the acetic acid quality), wherein the solid phase is a strongly acidic ion exchange resin Amberlyst 36 (produced by Rohm and Haas, USA), and the liquid catalyst is a pair of Toluenesulfonic acid, accounting for 50%. The conversion rate of acetic acid in this process is 94.5%, the content of butene in the gas after the reaction is 1.2%, and the production capacity is 1020kg / h.

Embodiment 3

[0039] Adopt the reaction equipment identical with embodiment 1, be similar to embodiment 1 operating method, the mol ratio of acetic acid and butene is 1: 0.8, 130 ℃ of reaction temperatures, the pressure of jet collision flow tower reactor 5 is 1.4MPa (table pressure), the catalyst used is a solid-liquid mixed acid catalyst (catalyst amount accounts for 5% of the acetic acid quality), wherein the solid phase is strongly acidic ion exchange resin Amberlyst 35 (produced by Rohm and Haas, USA), and the liquid catalyst is phosphoric acid , Phosphoric acid accounted for 40%. The conversion rate of acetic acid in this process is 91%, the content of butene in the gas after the reaction is 0.04%, and the production capacity is 970kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com