Polymer surface fluorination technique

A polymer and chemical process technology, applied in the field of polymer surface treatment technology, can solve the problems of large loss of treatment efficiency and long reaction time, and achieve the effects of saving fluorination time, improving production efficiency and improving barrier effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

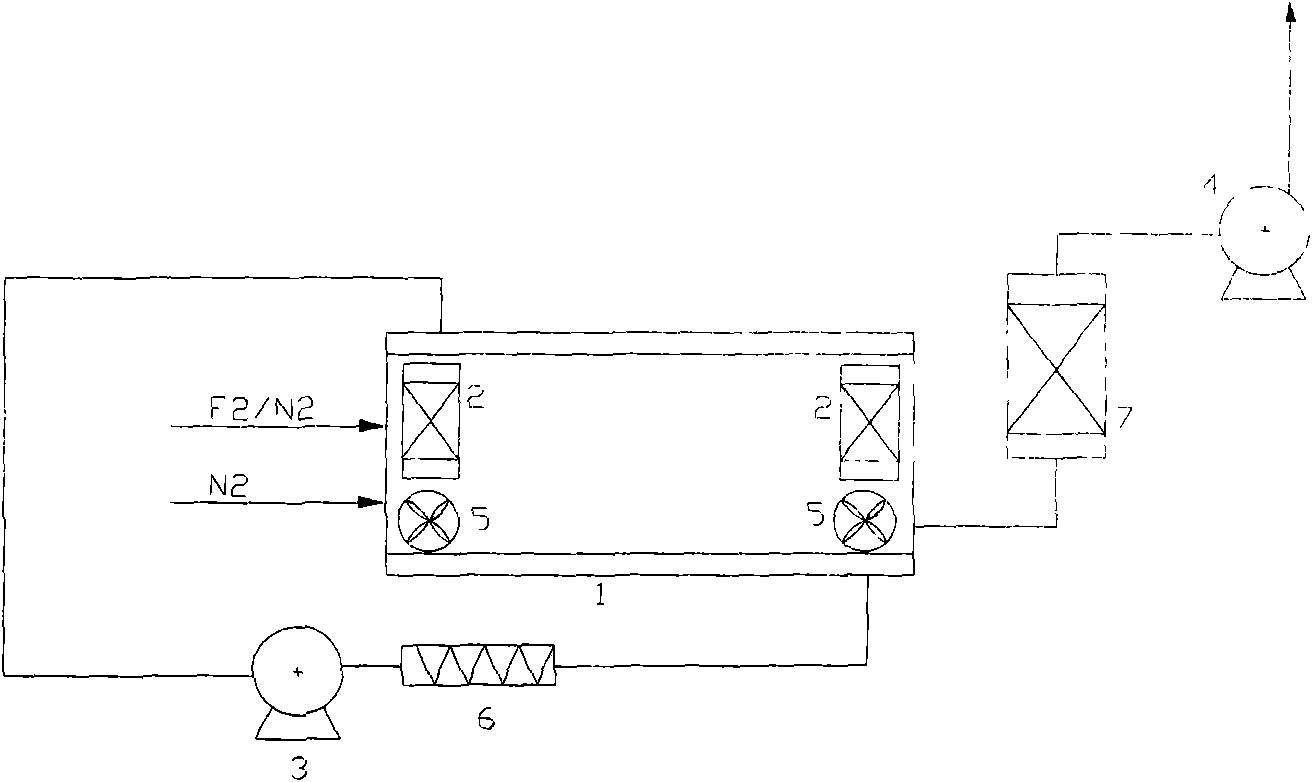

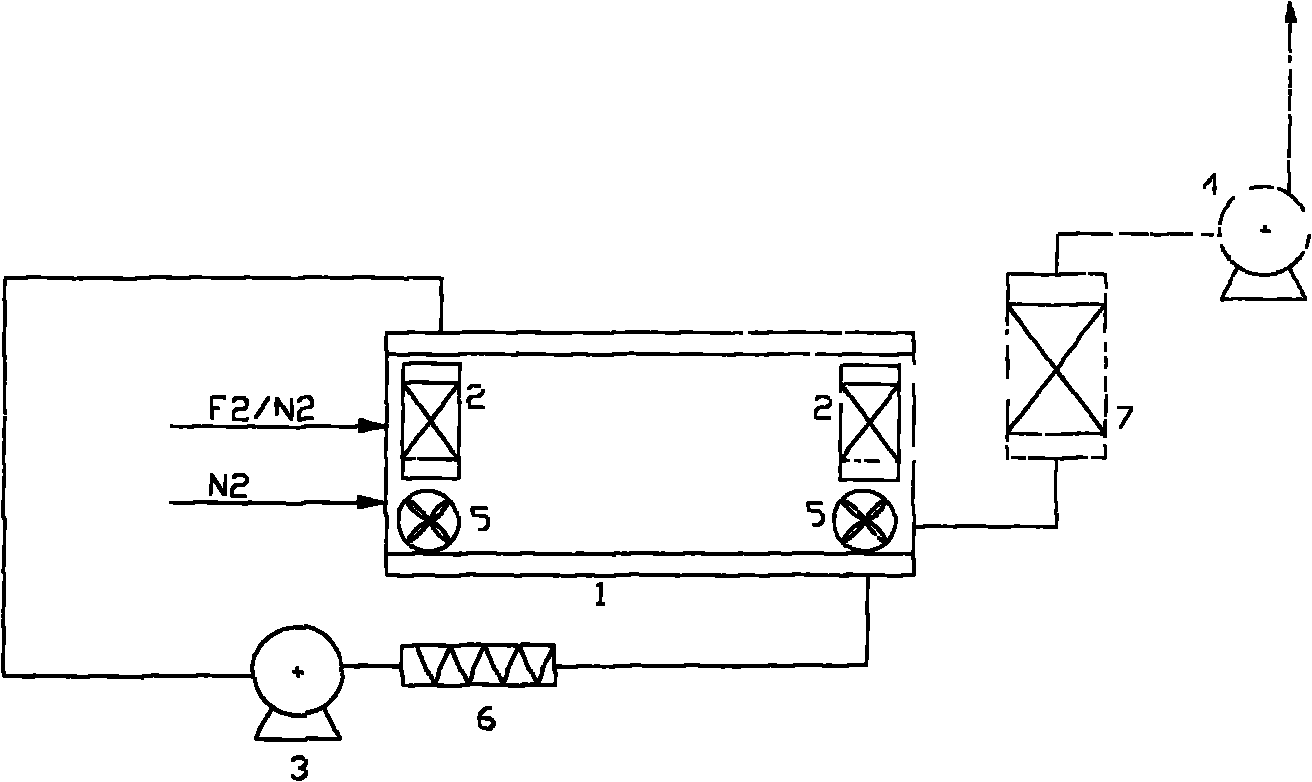

Image

Examples

Embodiment 1

[0025] Put 500 220ml HDPE oil tanks into the fluorination furnace, and put 3000kg of adsorbent at the same time; close the furnace door, use circulating hot water to heat the furnace to 70°C, evacuate and replace it with high-purity nitrogen twice, and feed 20 % Fluorine nitrogen to the pressure of -0.02MPa in the fluorination furnace, start the forced circulation of gas in the fluorination furnace, react for 20 minutes, and keep the temperature in the fluorination furnace at 70-75°C. Evacuate the gas in the furnace and replace it twice with high-purity nitrogen, take out the fuel tank, observe the obvious passivation effect on the surface of the fuel tank, measure the fluorine content on the surface of the fuel tank to 315 μg / cm2, fill the fuel tank with 93# ethanol gasoline, and perform solvent penetration according to EPA standards According to the test, the permeability is 0.28g / m2.d under the constant temperature condition of 40°C, which is far lower than the EPA standard ...

Embodiment 2

[0027] Put 250 500ml HDPE oil tanks into the fluorination furnace, and put 2500g of adsorbent at the same time; close the furnace door, heat the furnace to 70°C with circulating hot water, evacuate and replace it with high-purity nitrogen twice; % Fluorine nitrogen to the pressure of -0.02MPa in the fluorination furnace, start the forced circulation of the gas in the fluorination furnace, react for 40 minutes, and keep the temperature in the fluorination furnace at 70-75°C; evacuate the gas in the furnace and replace it with high-purity nitrogen twice, Take out the fuel tank; observe the obvious passivation effect on the surface of the fuel tank, and measure the fluorine content on the surface of the fuel tank to 280μg / cm2; fill the fuel tank with 93# ethanol gasoline, and conduct a solvent penetration test according to EPA standards, and the permeability is 0.35g / m2 at a constant temperature of 40°C .d, far below the EPA standard requirements.

Embodiment 3

[0029] Put 800 150ml HDPE oil tanks into the fluorination furnace, and put 2500g of adsorbent at the same time; close the furnace door, heat the furnace to 50°C with circulating hot water, evacuate and replace it with high-purity nitrogen twice; Fluorine gas to the pressure in the fluorination furnace is -0.08MPa, and then high-purity nitrogen gas is introduced until the pressure in the fluorination furnace is -0.04MPa, the internal forced circulation of the gas in the fluorination furnace is started, and the reaction is 60min, and the temperature in the fluorination furnace is maintained at 50 ~55°C; evacuate the gas in the furnace and replace it twice with high-purity nitrogen, take out the fuel tank; observe the surface of the fuel tank to show obvious passivation effect, and measure the fluorine content on the surface of the fuel tank to 305 μg / cm2; fill the fuel tank with 93# ethanol gasoline, according to EPA The solvent penetration test is carried out according to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com