High-efficiency energy-saving sewage treatment method and device

A sewage treatment method and sewage technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of failing to meet the use standards of industrial water, failing to realize the requirements of reuse and zero discharge, and the inability of the MVR evaporation system to further achieve the goal of enrichment, etc. , to achieve the effect of reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

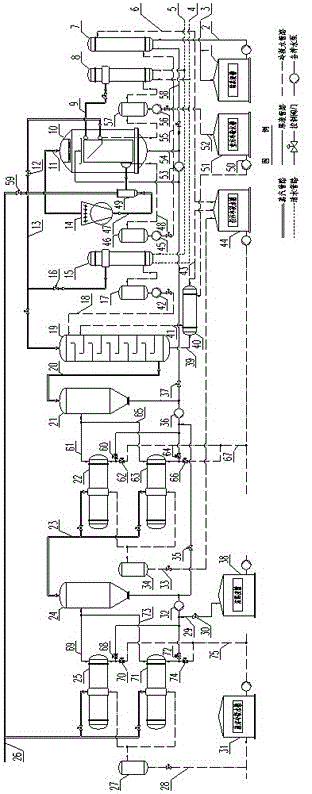

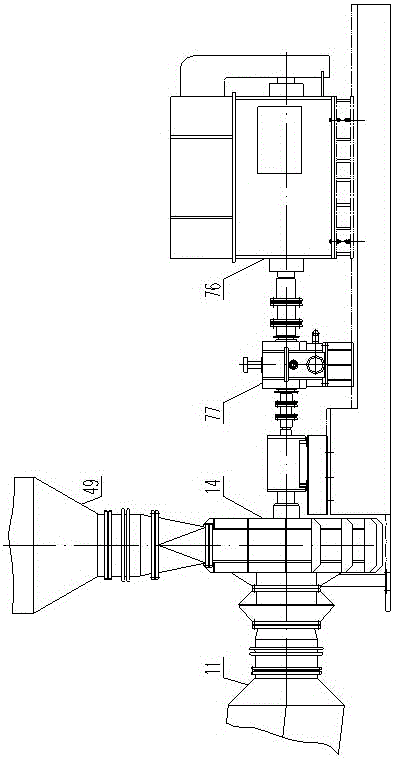

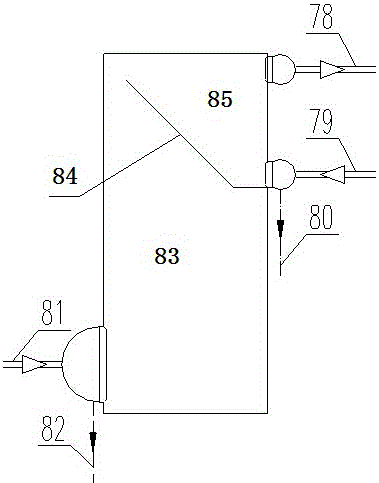

[0038] The present invention is explained in conjunction with the accompanying drawings by using an embodiment of an MVR system supporting a two-stage forced circulation evaporator for treating black liquor wastewater in the papermaking industry.

[0039] In the sewage treatment method and device system of the present invention, at first the black liquor waste water is collected in the dilute black liquor tank 1 through the dilute black liquor collecting pipe 3 from the pulp washing section, and then is transported by a water pump from the dilute black liquor feeding pipe 2 into the The black liquor preheater 7 exchanges heat with the light-polluted condensed water from the MVR evaporator 10, thereby heating the dilute black liquor to a certain temperature and creating preliminary conditions for concentrated evaporation, while the light-polluted condensed water is reduced through heat exchange. To a certain temperature, make full use of its heat energy. The heated dilute black...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com