Microwave catalytic reactor system

A microwave reactor and microwave catalysis technology, applied in the chemical/physical/physical-chemical process of applying energy, etc., can solve the problems of low processing efficiency, inability to continuously adjust, and the inability of continuous operation of reaction materials to achieve structural science. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

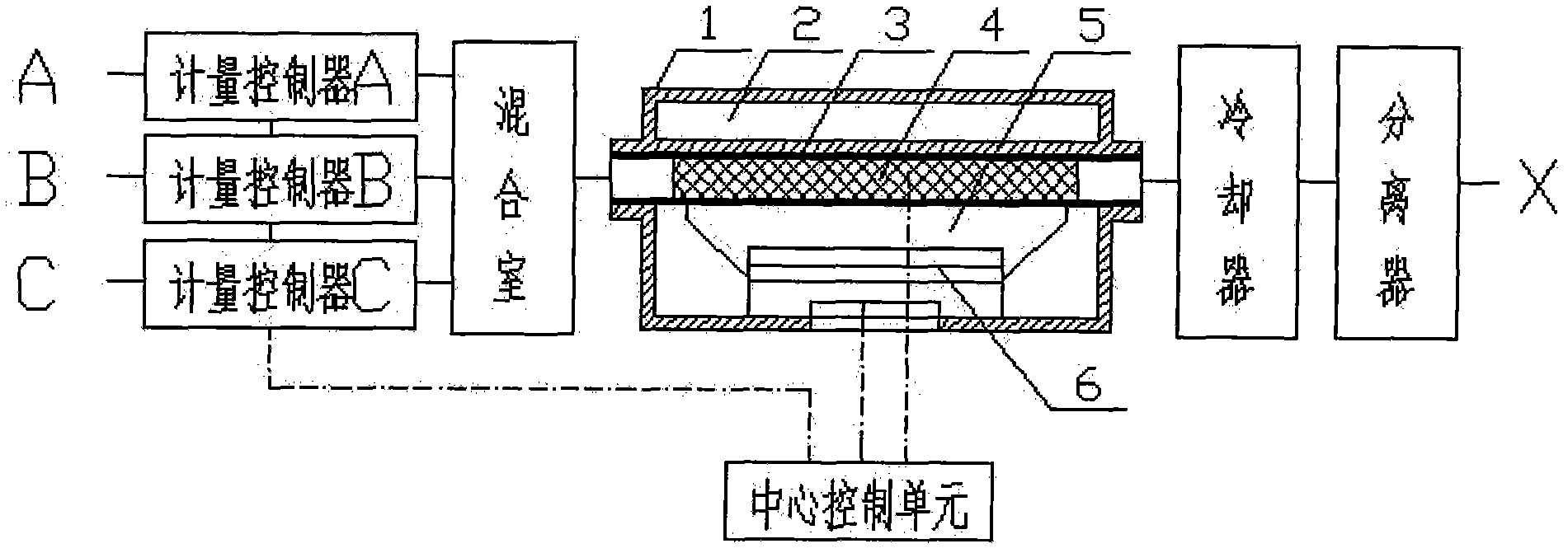

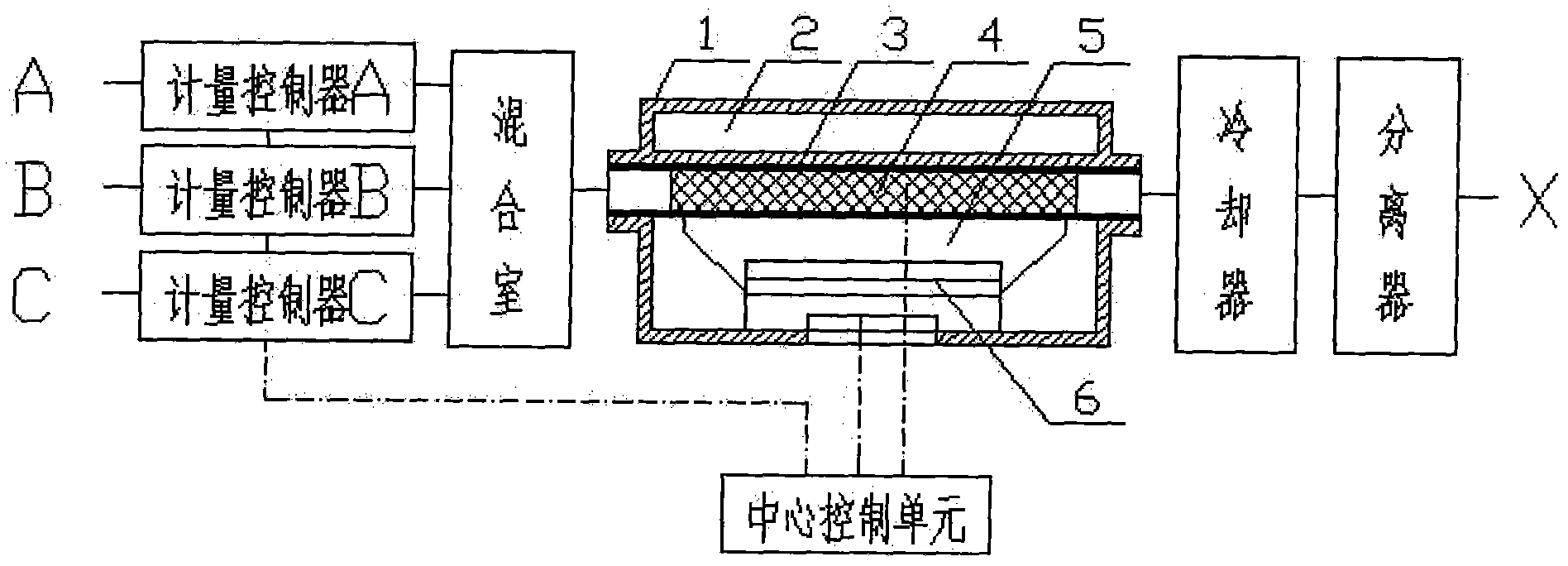

[0024] A feed port A is directly connected to the microwave reactor, and then discharged through the discharge port X. A reaction tube 3 and a microwave resonance cavity 5 are installed in the reactor body 1 of the microwave reactor; a microwave tube 6 is installed in the microwave resonance cavity 5; a catalyst 4 is filled in the reaction tube 3; and a catalyst 4 is installed Temperature sensor; the control circuit and temperature sensor of the microwave tube 6 are electrically connected to the central control unit. A forced-circulating cooling water chamber 2 is arranged between the outer wall of the reaction tube 3 and the reactor body 1, a water tank for forcedly circulating cooling water is installed outdoors, and the cooling water chamber 2 is connected to the water tank through a pipe and a water pump.

Embodiment 2

[0026] On the basis of Example 1, a metering controller is added between the feed port A and the microwave reactor, and the others are the same as in Example 1. The control circuit of the added metering controller is also electrically connected with the central control unit.

Embodiment 3

[0028] On the basis of Example 2, the feed port is A, B or the feed port is A, B, C or more. In this embodiment, the three feed ports are A, B, C, and the matching metering controller There are also three metering controllers A, metering controller B, and metering controller C. The mixing chamber is added before the microwave reactor. The others are the same as in Example 2. The control circuit of the added metering controller is also electrically connected with the central control unit.

[0029] The above embodiments 1-3 are used to treat waste gas or wastewater. Such as:

[0030] Catalyst 4 is 5ml of activated carbon.

[0031] Standard NO gas enters from the feed port A, oxygen enters from the feed port B, and mixes through the mixing chamber. The NO gas flow rate is 160ml / min, and the space velocity is 1920h -1 ; The intake NO content is 1000ppm, the oxygen content is 5.88%, the microwave power selects automatic gear control, and the temperature of the microwave catalytic react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com