Method and device for processing high-saline organic wastewater

A technology of organic wastewater and treatment methods, which is applied in water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of heat energy waste, cooling water consumption, etc., and reduce energy consumption , less land occupation and smaller volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

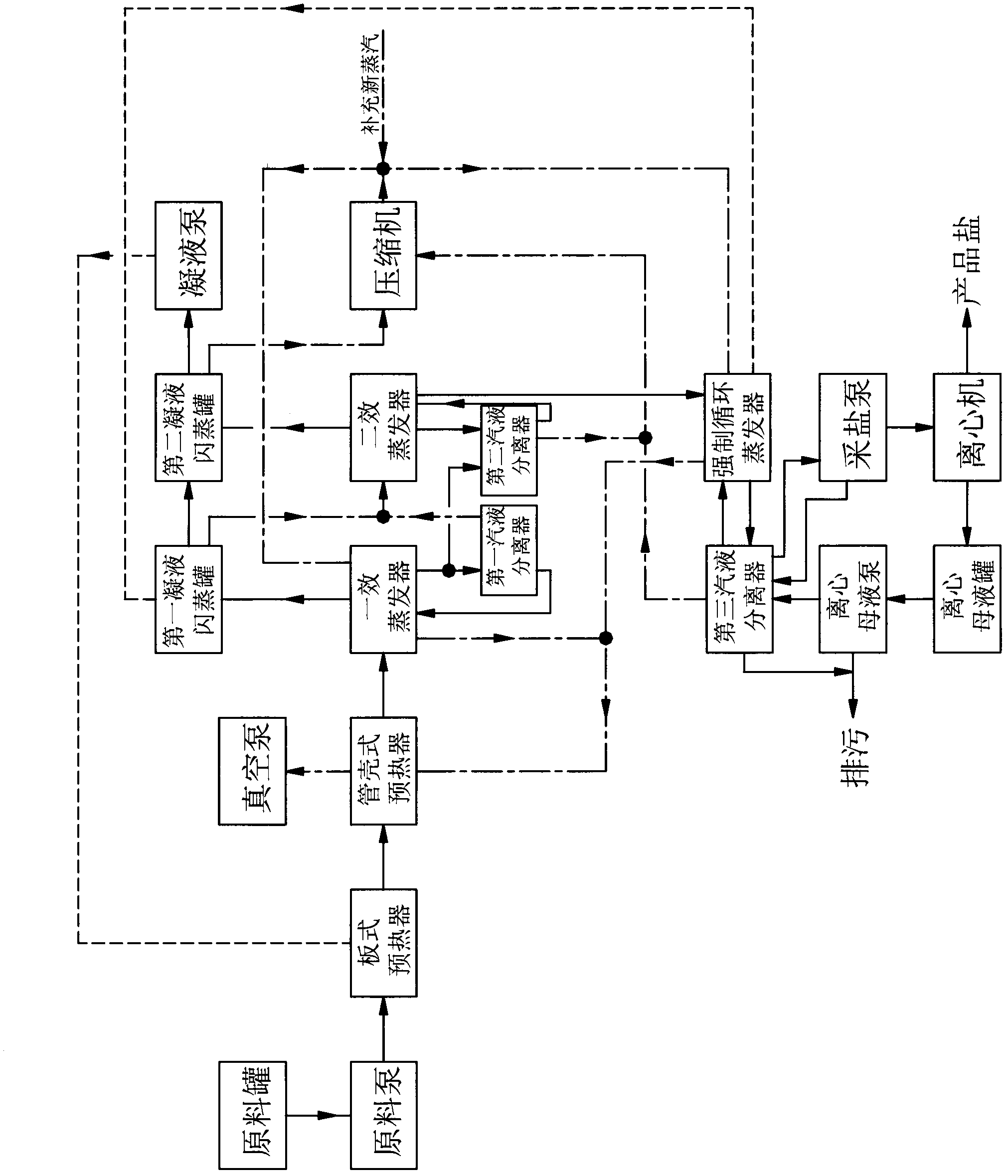

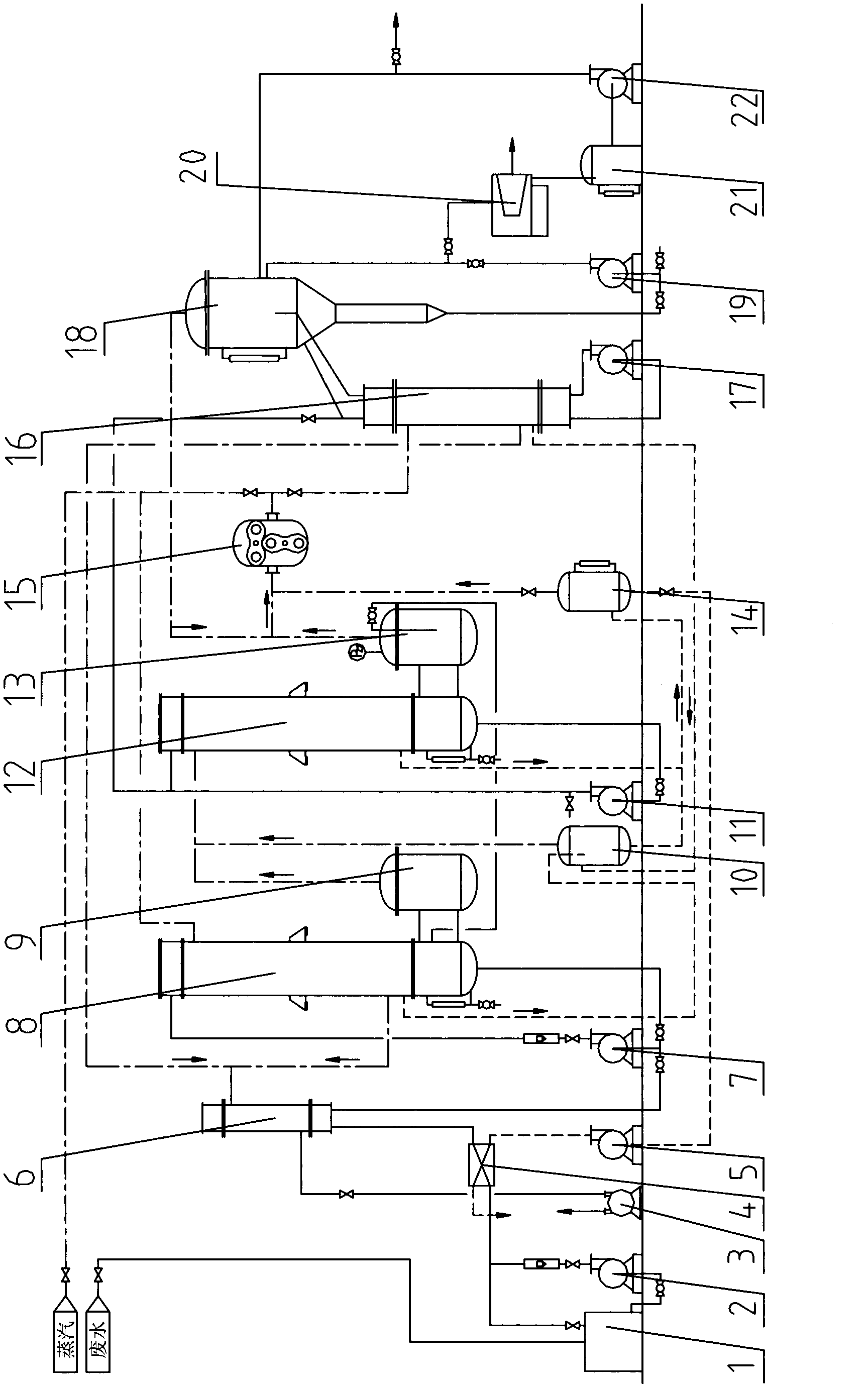

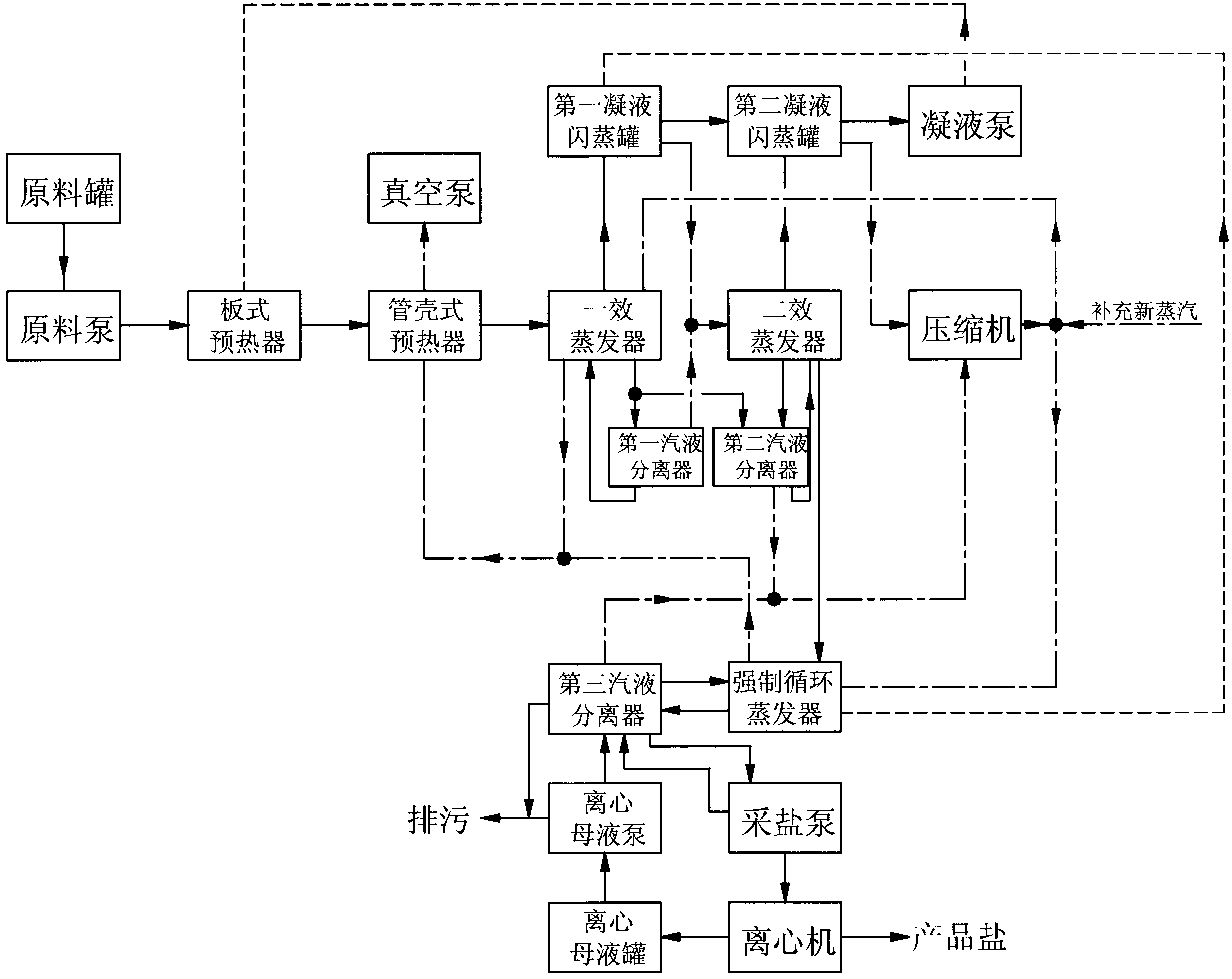

[0030] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0031] The best embodiment of the treatment method of high-salt organic wastewater of the present invention adopts a mechanical vapor recompression evaporation system for wastewater treatment, which has the following steps:

[0032] ①Wastewater preheating: Wastewater is preheated at an absolute pressure of 57861-60313Pa to a boiling temperature of 81-82°C;

[0033] ②Primary evaporation: The preheated wastewater enters the first-effect evaporator 8 for heat exchange. The vapor phase temperature of the first-effect evaporator 8 is 78-79℃, the absolute pressure is 43837-45603Pa, and the liquid-phase temperature of the first-effect evaporator 8 is 81- 82°C, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com