Forced circulating extraction method in production of acesulfame

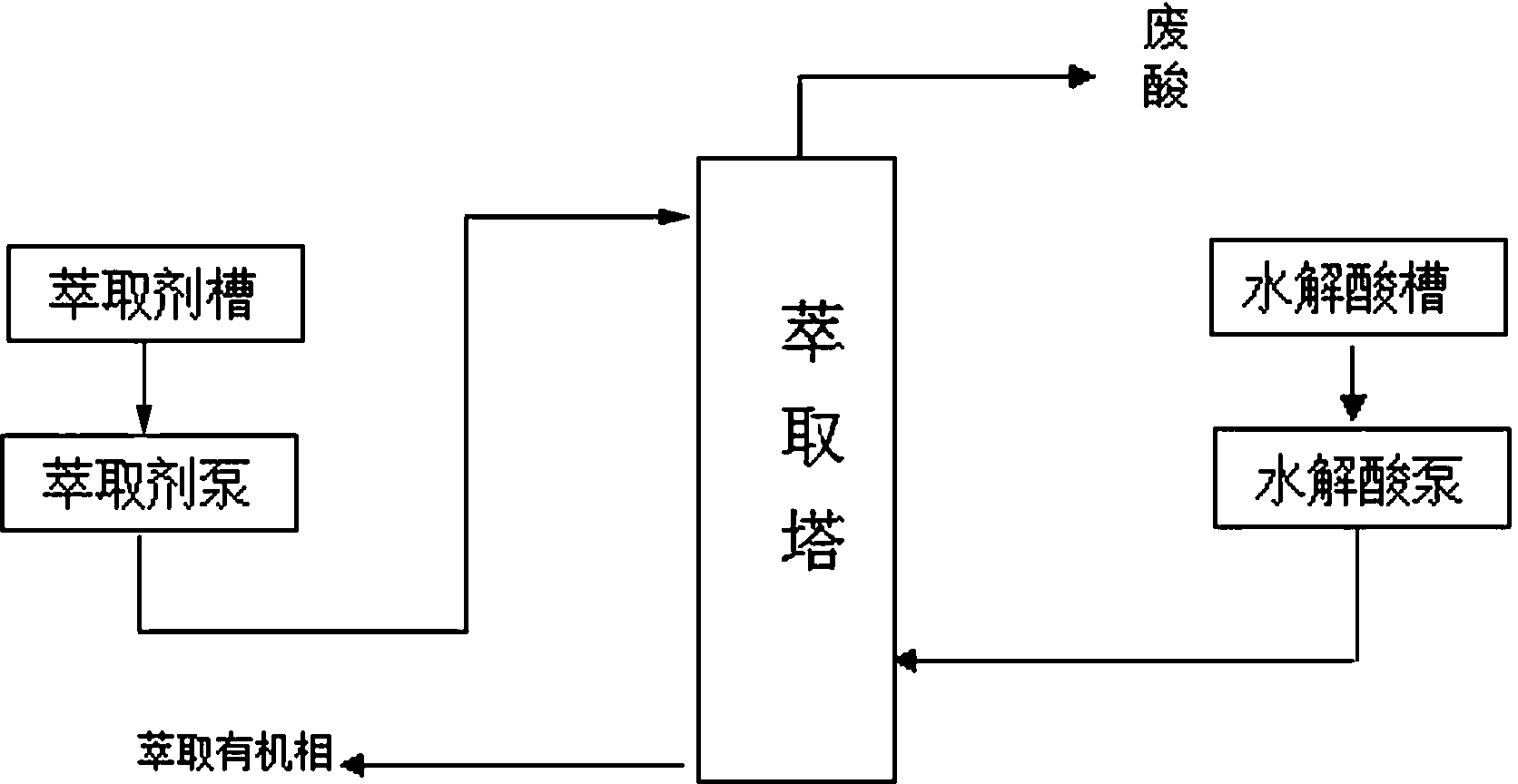

A technology of forced circulation and forced circulation pump, which is applied in liquid solution solvent extraction, organic chemistry, etc., can solve the problems of uneven contact mixing, low extraction efficiency, partial flow of extraction agent and hydrolysis acid phase, etc., so as to simplify production operations and reduce The labor intensity of workers and the effect of reducing the difficulty of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

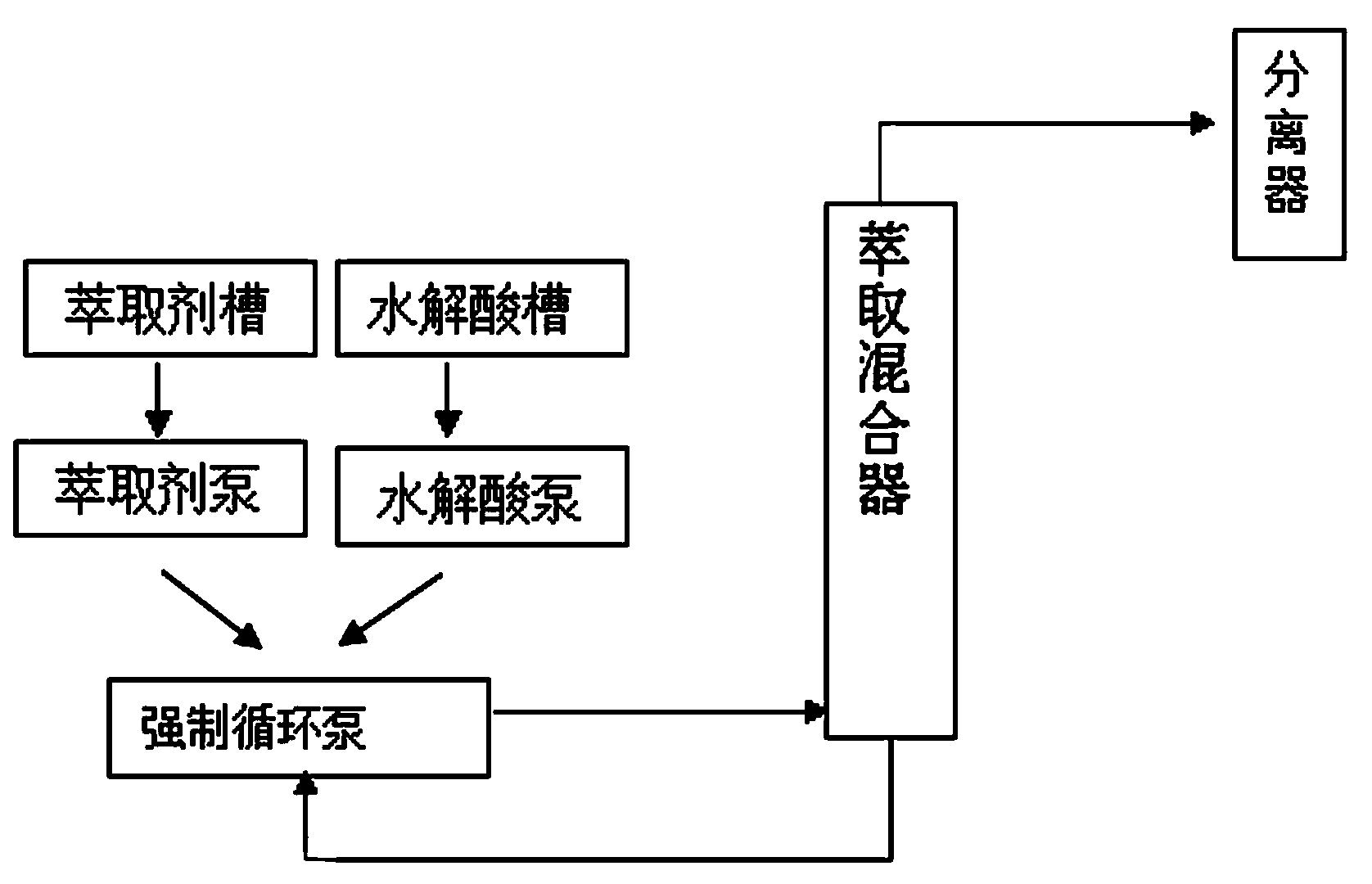

[0018] A forced circulation extraction method in the production of acesulfame K, comprising the following steps:

[0019] 1) Inject the extraction agent into the extraction mixer through the extraction pump;

[0020] 2) Turn on the forced circulation pump so that the extraction agent has a volume of 2 m 3 circulation in the mixer;

[0021] 3) Turn on the hydrolytic acid pump, press the hydrolytic acid by 5 m 3 / h pumped into the extraction mixer;

[0022] 4) Adjust the extraction agent flow rate to 16 m 3 / h, at the overflow port at the top of the mixer, with the increase of the feed of the extractant pump and the hydrolysis acid pump, a part of the material overflows out of the extraction mixer and enters the separator for separation;

[0023] 5) The separated acid continues to enter the extraction mixer for re-extraction, and the organic phase enters the extraction organic phase tank for neutralization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com