Compound mouldproof agent with acidizing effect and preparation method thereof

A technology of antifungal agent and propionic acid, which is applied in the field of feed safety and preservation, can solve the problems of acid abuse or vacancy, and achieve the effects of suppressing volatility, solving high conversion rate and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

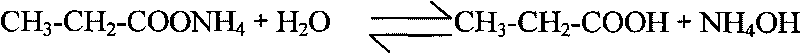

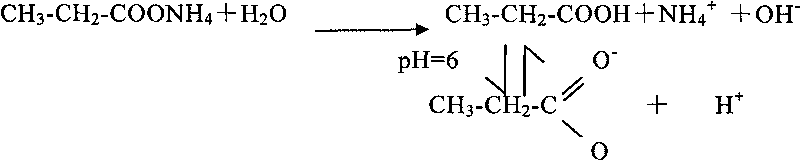

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation method of composite antifungal agent solid powder, the steps are as follows:

[0044] (1) Preheat the liquid ammonia to 40-45°C with an ammonia preheater, control the pressure at 1-1.5MPa, and then disperse it through a disperser, and then evenly and slowly pass it into the reaction kettle with an appropriate amount of propionic acid, and use 60- Stir the reaction at a speed of 80r / min, and at the same time turn on the cooling water to cool down, so that the exothermic temperature in the kettle does not exceed 100-110°C, and the weight content of free propionic acid in the reaction kettle is reduced to 1% of the whole liquid by sampling and testing (conventional acid-base titration method). When it is about 80%, stop feeding ammonia gas, continue to stir for 2-3 minutes, and cool down to get the mixture of propionic acid-ammonium propionate-ammonium dipropionate;

[0045] (2) Preheat the liquid ammonia to 45-50°C with an ammonia preheater...

Embodiment 2

[0049] The preparation method of composite antifungal agent solid powder, the steps are as follows:

[0050] Steps (1), (2) and (4) are the same as Example 1, and the difference of step (3) is only to take 45 parts by weight of propionic acid-ammonium propionate-ammonium dipropionate mixture and 10 parts by weight of glacial acetic acid-acetic acid Ammonium-Ammonium Diacetate Mixture.

Embodiment 3

[0052] The preparation method of composite antifungal agent solid powder, the steps are as follows:

[0053] Steps (1) and (2) are the same as in Example 1, the difference of step (3) is only to take 40 parts by weight of propionic acid-ammonium propionate-ammonium dipropionate mixture and 5 parts by weight of glacial acetic acid-ammonium acetate-diacetic acid Ammonium mixture, the difference in step (4) is to weigh 24 parts by weight of activated silicon dioxide in the mixer, spray the mixed solution of (3) under stirring, after the absorption is completed, weigh 4 parts by weight of fine powder Benzoic acid, 1 weight part of sorbic acid and 26 weight parts of zeolite powder are added, stirred evenly, sieved, inspected and packaged to obtain a composite antifungal agent solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com