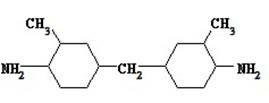

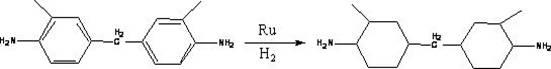

Synthesizing method of 3,3'-dimethyl-4,4'-diamido-dicyclohexyl methane

A technology of diaminodicyclohexylmethane and diaminodicyclohexyl is applied in the field of fine chemical synthesis, which can solve the problem of high equipment requirements, and achieve the effects of prolonging the process cost, eliminating waste of resources and having good reaction atom economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Put 226g MDT, 226g MACM, 11.3g Ru / SiO into the hydrogenation kettle 2 , and add 0.11g CaO, and replace with nitrogen and hydrogen after feeding. Start stirring, raise the temperature to 120°C, and control the temperature between 120-140°C and the pressure between 2.0-4.0MPa. The hydrogen absorption is completed after 32 hours of reaction, continue to keep warm for 2 hours, cool to 40°C, discharge, filter, Then product is distilled under 10mmHg vacuum, obtains product 219g, content 99.6%, yield 92%.

Embodiment 2

[0031] Example 2 Put 226g MDT, 226g MACM, 11.3g Ru / SiO into the hydrogenation kettle 2, and add 0.09gBaO, and replace with nitrogen and hydrogen after feeding. Start stirring, raise the temperature to 135°C, and control the temperature between 140-160°C and the pressure between 2.0-4.0MPa. After 22 hours of reaction, the hydrogen absorption is completed, continue to keep warm for 1.5h, cool to 40°C, discharge, and filter , Then distill the product under 10mmHg vacuum, obtain product 226.6g, content 99.5%, yield 99.5%.

Embodiment 3

[0032] Example 3 Put 226g MDT, 271g MACM, 18.1g Ru / SiO in the hydrogenation kettle 2 , and add 0.12gMgO, and replace with nitrogen and hydrogen after feeding. Start stirring, raise the temperature to 135°C, and control the temperature between 140-160°C and the pressure between 4.0-6.0MPa. The hydrogen absorption is completed after 17 hours of reaction, continue to keep warm for 2.5h, cool to 40°C, discharge, and filter , Then distill the product under 10mmHg vacuum, obtain product 236.1g, content 99.7%, yield 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com