High-temperature-resistant liquid sealant

A technology of liquid sealing and high temperature resistance, which can be applied in other chemical processes, chemical instruments and methods, etc. It can solve the problems of high viscosity, large shrinkage, and low solid content of products, and achieve low viscosity, small shrinkage, and good thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

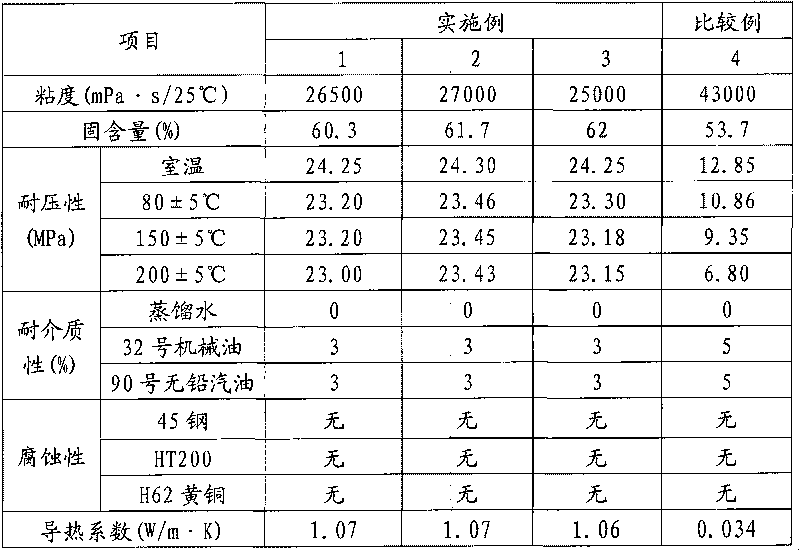

Examples

Embodiment 1

[0030] According to the proportion by weight, 25 parts of methylcyclohexane and 13 parts of butyl acetate are added to the reactor, and at a stirring speed of 300 rpm, drop into the hydrogenated nitrile rubber compound (proportion by weight: hydrogenated Nitrile rubber: nano cerium oxide: quartz powder: aluminum silicate: carbon black N550: stearic acid = 15:3:12:5:2:0.1, just crushed after mixing evenly) 45 parts, terpene phenolic resin 6.8 parts of SP-46OB, 3.5 parts of fumed silica, 5 parts of aluminum powder, 1.5 parts of dibutyl phthalate, 0.2 parts of γ-aminopropyltriethoxysilane, stir for 5 hours until the glue is uniform, and cool To normal temperature, the finished product is discharged.

Embodiment 2

[0032] According to the proportion by weight, 22 parts of methylcyclohexane and 14 parts of butyl acetate are added to the reactor, and at a stirring speed of 300 rpm, drop into the hydrogenated nitrile rubber compound (proportion by weight: hydrogenated Nitrile rubber: nano cerium oxide: quartz powder: aluminum silicate: carbon black N550: stearic acid = 20:5:8:7:3:0.3, just crush after mixing evenly) 45 parts, terpene phenolic resin 5.5 parts of SP-12, 3.2 parts of fumed silica, 8 parts of aluminum powder, 2 parts of dioctyl phthalate, 0.3 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, stirred for 5 Hours until the glue is uniform, cooled to room temperature, and the finished product is discharged.

Embodiment 3

[0034] According to the proportion by weight, 22 parts of methylcyclohexane and 14 parts of butyl acetate are added to the reactor, and at a stirring speed of 250 rpm, drop into the hydrogenated nitrile rubber compound (proportion by weight: hydrogenated Nitrile rubber: nano cerium oxide: quartz powder: aluminum silicate: carbon black N550: stearic acid = 25:8:2:10:4:0.5, just crush after mixing evenly) 43 parts, terpene phenolic resin 5.5 parts of SP-154, 3.2 parts of fumed silica, 10 parts of aluminum powder, 1.8 parts of decyl phthalate, 0.5 parts of γ-methacryloxypropyl trimethoxysilane, stirred for 4.5 hours until the glue Evenly, cool to normal temperature, and the finished product is discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com