Method for distilling normal heptane and methyl - cyclohexane by using combination of rectification and compound extracted rectification

A technology of methylcyclohexane and extractive distillation, which is applied in the field of rectification and compound extractive distillation and separation of n-heptane and methyl-cyclohexane, can solve the problem of low yield in the separation process and difficulty in obtaining methyl cyclohexane. -Cyclohexane, complex process and other problems, to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

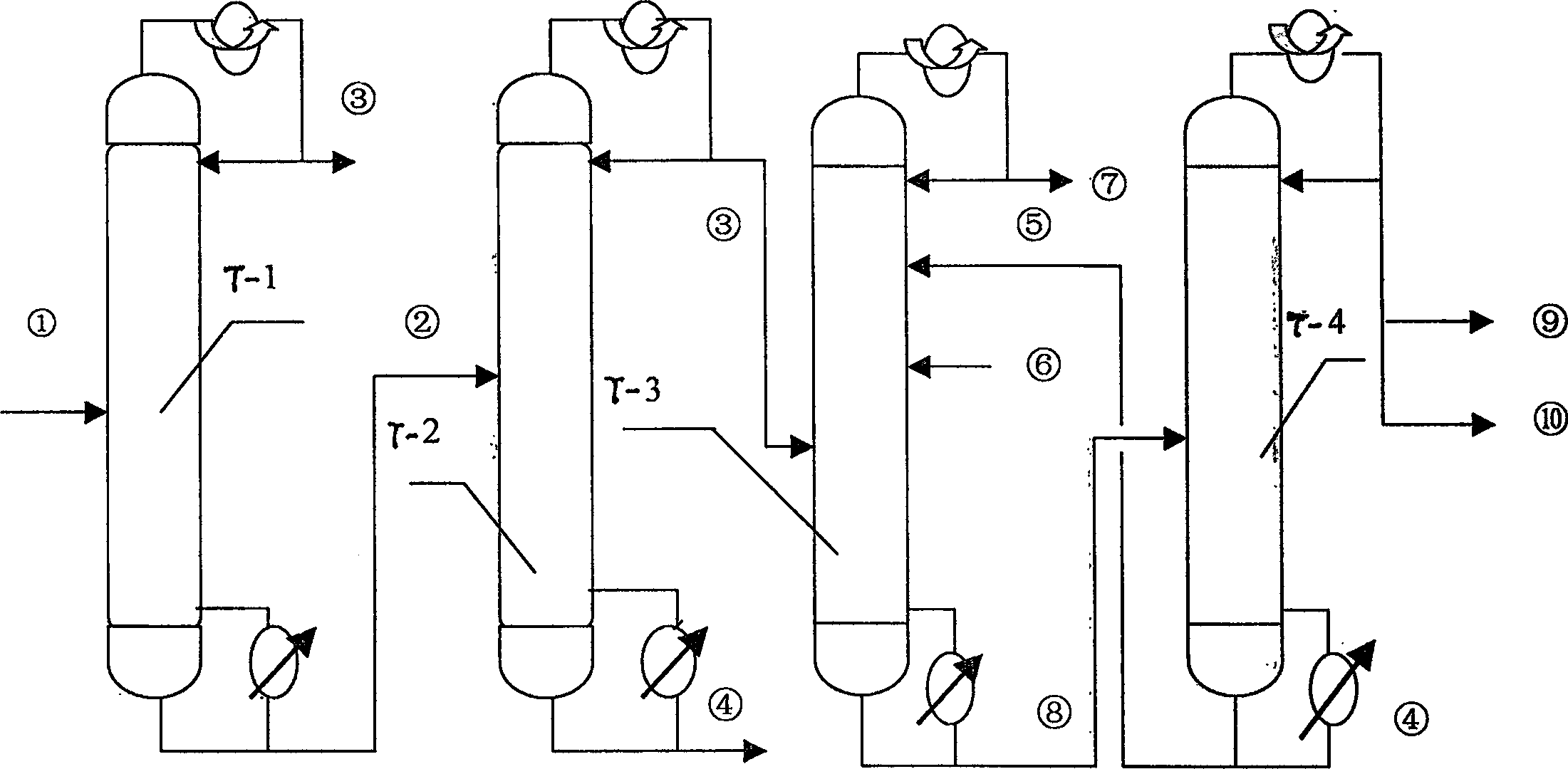

[0022] Example 1: No. 120 solvent oil extracted from Yangzi Petrochemical Olefin Factory was used. The solvent oil was analyzed by HP chromatograph. The composition is shown in Table 2, and the compositions in Table 2 are all in mass content. process such as figure 1 As shown, the raw material ① is separated by primary distillation tower T-1, and the light fraction can be cut off. The temperature at the top of the tower is controlled at 94-96°C, the reflux ratio (R) is 2-3, and the temperature at the bottom of the tower is 110-115°C. The bottom is obtained containing more than 34.5% n-heptane and more than 28.9% methylcyclohexane material 2, as shown in Table 3 for details; tower T-1 bottom material 2 is processed by rectifying tower T-2, and the temperature at the top of the tower is controlled 97~101℃, the reflux ratio (R) is 3~4, the temperature of the tower bottom is 112~117℃, and the top of the rectifying tower T-2 can obtain more than 51% of n-heptane and more than 44% o...

Embodiment 2

[0028] Embodiment 2 is substantially the same as embodiment 1, but the mass ratio of composite extractant is,

[0029] Raw materials: S1:S2=1:0.8:0.8.

Embodiment 3

[0030] Embodiment 3 is substantially the same as embodiment 1, but the mass ratio of composite extractant is,

[0031] Raw materials: S1:S2=1:1.2:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com