Waterborne polyurethane with solid content of 60%

A water-based polyurethane, polyurethane technology, applied in the field of polymer materials, can solve problems such as difficulty in introducing sulfonic acid groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

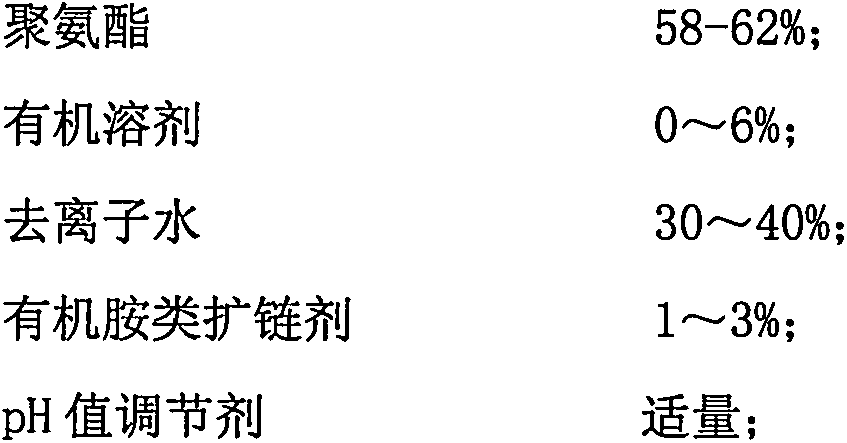

[0052] Water-based polyurethane comprises the following components by weight percentage:

[0053] (1) Polyurethane, 60%

[0054] Among them, by weight percentage, polyester polyol (molecular weight: 2000) containing sulfonate group, 30%; polyester polyol (molecular weight: 2000) containing highly branched chain structure, 45%; Isocyanate (IPDI), 6.9%; Dicyclohexylmethane diisocyanate (HMDI), 16.1%; Dimethylolpropionic acid, 2.0%.

[0055] (2) N-methylpyrrolidone (organic solvent), 5%

[0056] (3) Deionized water, 31.2%

[0057] (4) Ethylenediamine (organic amine chain extender), 2.3%

[0058] (5) Triethylamine (pH regulator), 1.5%.

[0059] The preparation method is as follows: using the prepolymer mixing method, first add polyester polyols containing sulfonate groups, polyester polyols containing highly branched chain structures, dimethylol propionic acid, and N-methylpyrrolidone according to the formula In the reaction kettle, add isophorone diisocyanate (IPDI) and dicy...

Embodiment 2

[0062] Water-based polyurethane comprises the following components by weight percentage:

[0063] (1) Polyurethane, 61%

[0064] Among them, by weight percentage, polyester polyol (molecular weight: 2000) containing sulfonate group, 32%; polyester polyol (molecular weight: 2000) containing highly branched chain structure, 48%; Isocyanate (IPDI), 9.25%; Dicyclohexylmethane diisocyanate (HMDI), 9.25%; Dimethylolpropionic acid, 1.5%.

[0065] (2) Acetone, which is half of the weight part of the polyurethane, is separated at last and is not included in the total weight percentage.

[0066] (3) Deionized water, 36.4%

[0067] (4) Ethylenediamine (organic amine chain extender), 1.5%

[0068] (5) Triethylamine (pH regulator), 1.1%.

[0069] The preparation method is: using the acetone method, first add polyester polyols containing sulfonate groups, polyester polyols containing highly branched chain structures, dimethylol propionic acid, and acetone into the reaction kettle accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com