Catalyst oxdie cyclohexane process

A catalytic oxidation and process technology, which is applied in the direction of oxidation reaction preparation, oxidation preparation of carbonyl compounds, hydrocarbon oxidation preparation of oxygenated compounds, etc., can solve the problems of difficult application in industrialization, difficulty in waste lye treatment, long process route, etc., and achieve reduction Production cost, load reduction, and the effect of reducing capacity expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

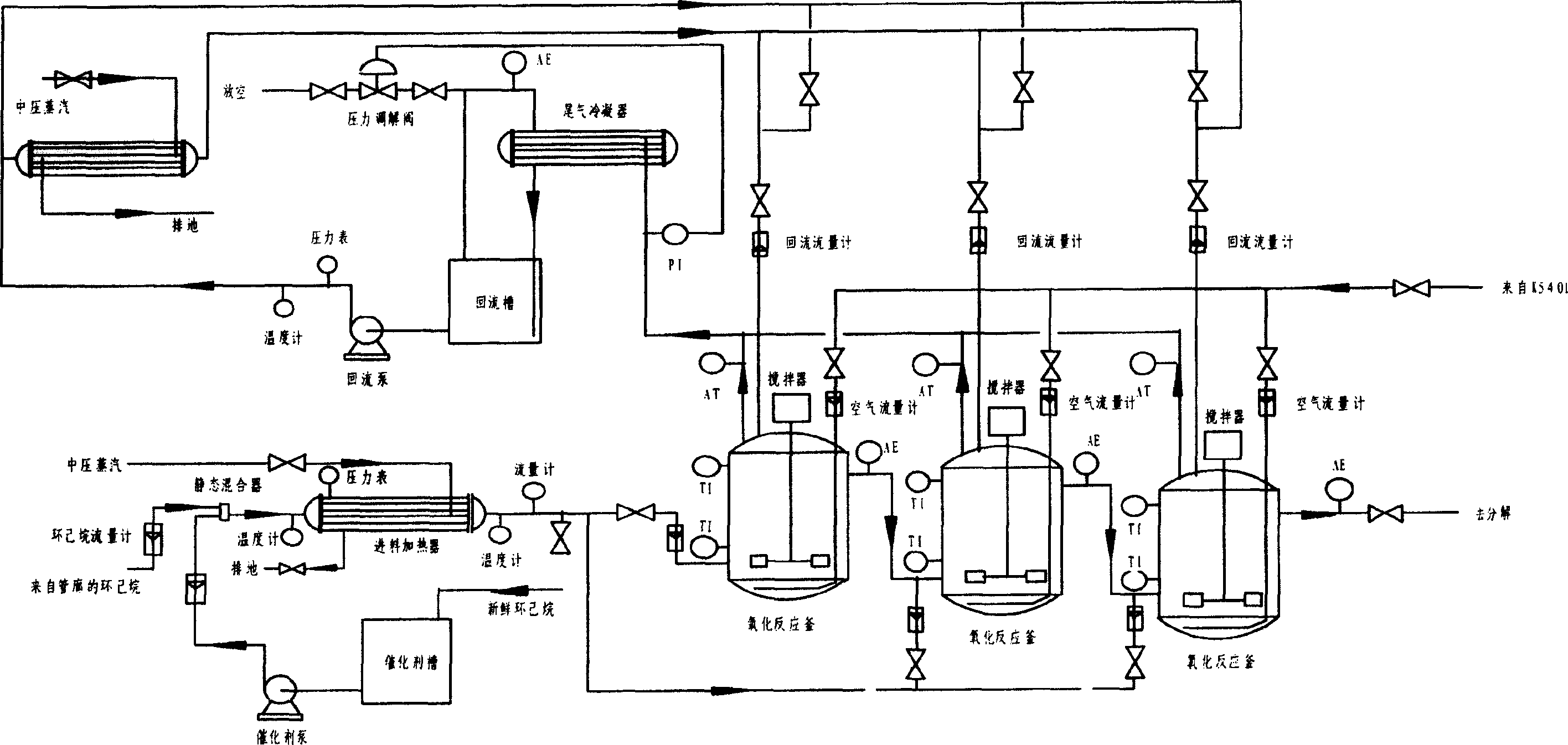

[0020] Example 1 in three 0.4M 3 In the oxidation reactor, the process flow chart is attachedfigure 1 , the oxidation reactor is three reactors connected in series with mechanical stirring, and the feeding amount of cyclohexane is kept at 1M 3 / hour, under the catalysis of metalloporphyrin, air is added from the bottom of the reactor, the reaction pressure is 0.9Mpa, and the cyclohexane carried by the oxidation tail gas is recovered by condensation and returned to the reactor. The oxidation product was cooled to 85°C and fed into a 0.4M 3 In the reaction kettle with mechanical stirring, the organic matter is mixed with the alkali, and the alkalinity is controlled at 1.0mg / meq. The acid in the organic matter reacts with the alkali to form organic acid sodium salt, and the ester organic matter is decomposed into organic acid and alcohol organic matter. The reactor The temperature is controlled at 90°C. ℃, the pressure is controlled at 0.3MPa, and the inorganic substances in t...

Embodiment 2

[0022] Embodiment 2 In a 80L bubble column reactor, the feeding amount of cyclohexane keeps 100L / per hour, and under the action of the catalyst, air is added from the bottom of the reactor, and the air oxidizes cyclohexane at a pressure of 0.9MPa, and the oxidation The cyclohexane carried by the tail gas is recovered by condensation and returned to the reactor.

[0023] serial number

Embodiment 3

[0024] Embodiment 3 In a 100L tubular reactor, the feeding rate of cyclohexane is maintained at 100L / hour, and the content of tetraphenylporphyrin cobalt catalyst in cyclohexane is 2.5mg / l, and air is added from the bottom of the reactor Under the action of the catalyst, air oxidizes cyclohexane at 148°C and 0.9MPa pressure, and the molar conversion rate of cyclohexane is 6.8%; the cyclohexane carried by the oxidation tail gas is recovered by condensation and returned to the reactor. The selectivity of cyclohexanol, cyclohexanone and cyclohexyl hydroperoxide among the oxidation products was 92%, of which cyclohexyl hydroperoxide accounted for 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com