Liquid potting composite of dicomponent addition type silicone rubber and preparation

A two-component, addition type technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of environmental pollution, strong corrosion, easy cracking, etc., and achieve the effect of convenient use and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides the preparation and curing method of this composition, the specific method is as follows: mix the above-mentioned (A) (B) (C) components with a kneader and knead, the heat treatment temperature is preferably 80 ~ 250 ° C, more preferably It is preferably 100-200°C, more preferably 140-180°C, and the heat treatment time is preferably 30 minutes to 10 hours, more preferably 1 to 4 hours, and even more preferably 1 to 2 hours, to prepare the basic composition; Then add (D) (E) (F) components to the basic composition, vacuum defoaming, and high temperature curing to obtain silicone rubber. The defoaming time is controlled at 5-30 minutes, and the curing temperature is preferably 100-180°C. for 2-10 minutes.

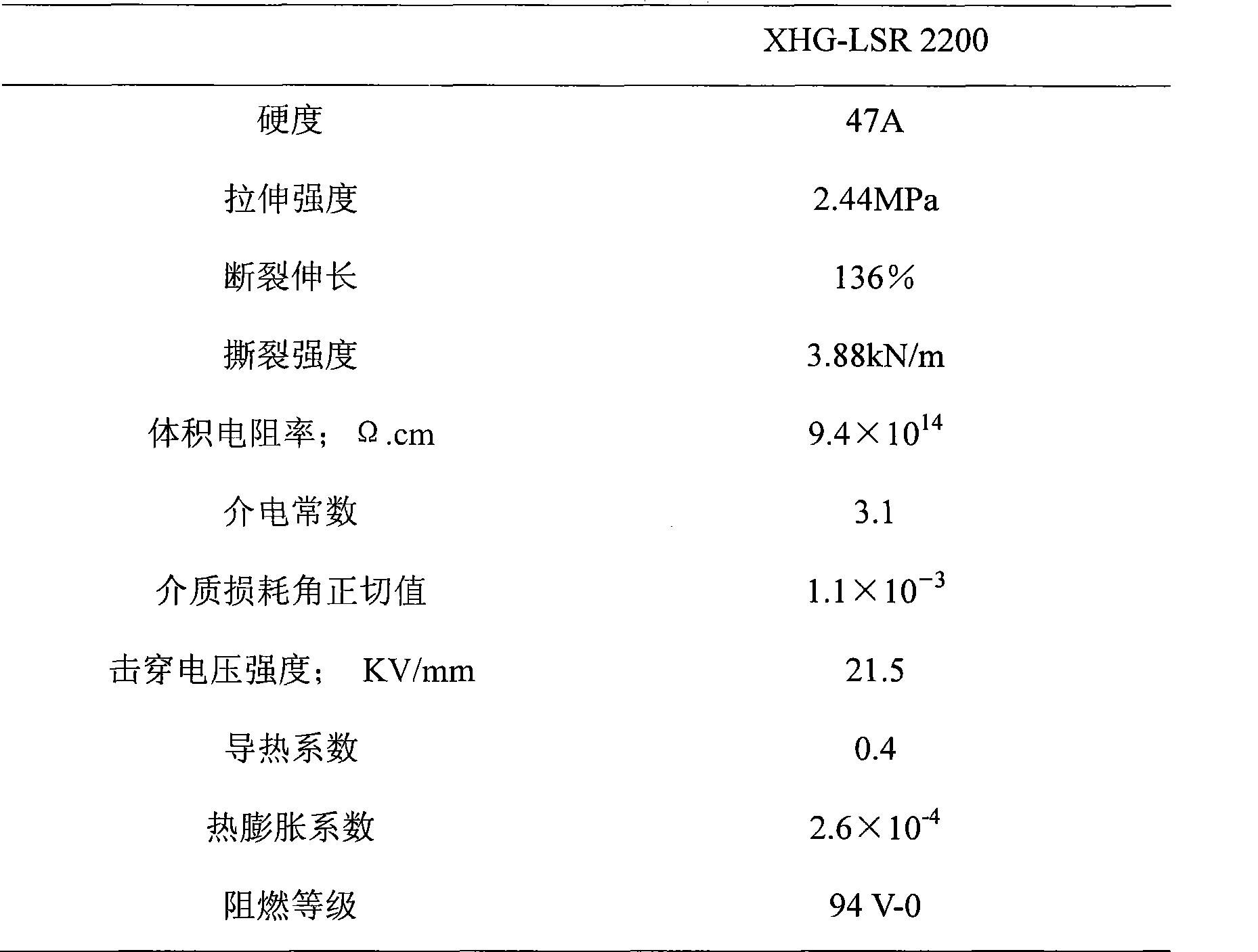

[0045] To test the performance of silicone rubber, the test standard is: Viscosity is measured by rotational viscometer, tensile strength: measured according to GB / T528-1998, tear strength: measured according to GB / T 529-1999, hardne...

Embodiment 1

[0047] Embodiment 1: 100 parts by weight of polyorganosiloxane with a viscosity of 1000 mPas, 40 parts by weight of high-purity quartz powder, and 6 parts of hydrogen-containing silicone oil with a hydrogen content of 0.3% and a viscosity of 30 mPas at 25° C. were kneaded with a kneader, and then heat-treated at 150° C. for 2 hours to prepare a base composition. With respect to 100 parts by weight of the above-mentioned base composition, 10 ppm of platinum catalyst (1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex), 0.5 wt % of hexyne Cyclohexanol as inhibitor and 0.004wt% benzotriazole as flame retardant. The mixture was defoamed in vacuum for 10 minutes, cured in a flat vulcanizer at 150° C. for 5 minutes to obtain a silicone rubber sheet with a thickness of 2 mm for performance testing.

Embodiment 2

[0048] Embodiment 2: 100 parts by weight of polyorganosiloxane with a viscosity of 1000 mPas, 40 parts by weight of high-purity quartz powder, and 10 parts of hydrogen-containing silicone oil with a hydrogen content of 0.18% and a viscosity of 30 mPas were kneaded with a kneader, and then heat-treated at 150° C. for 2 hours to prepare a basic composition. For 100 parts by weight of the above-mentioned basic composition, 10 ppm of platinum was added Catalyst, 0.5 wt% hexynylcyclohexanol as inhibitor and 0.004 wt% benzotriazole as flame retardant. The mixture was defoamed in vacuum for 10 minutes, and cured in a flat vulcanizer at 150° C. for 5 minutes to obtain a silicone rubber sheet with a thickness of 2 mm for performance testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com