Environmental-friendly drilling fluid lubricant

A technology of lubricants and surfactants, applied in the field of drilling fluid lubricants and their preparation, can solve the problems of retention in water and soil, pollute the environment, pollute the ecological environment, etc., and achieve excellent anti-wear performance and biodegradability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

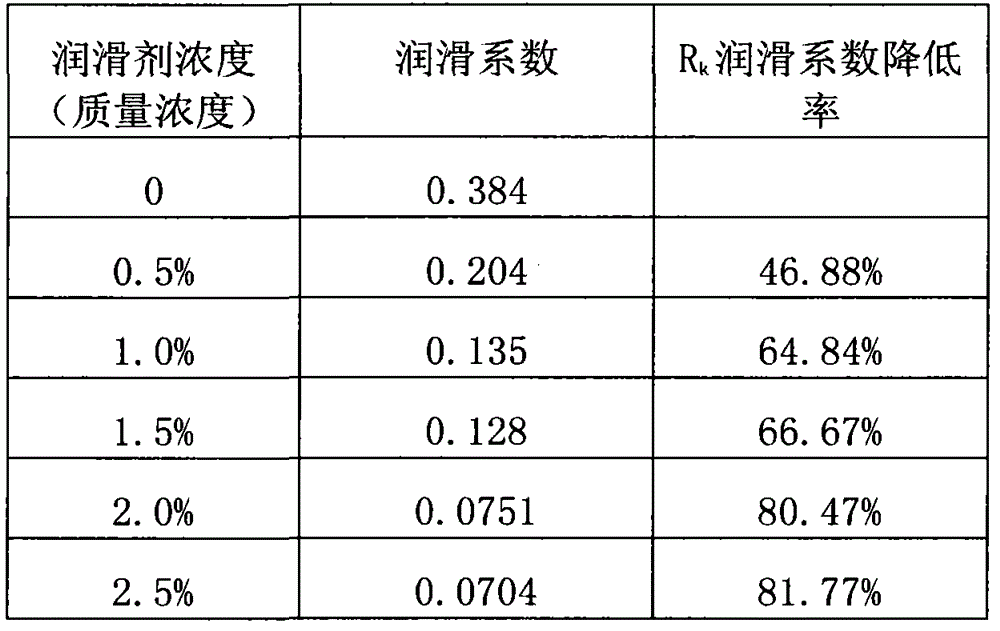

Examples

Embodiment 1

[0014] Example 1: In a reactor that can be heated and stirred, first add 25.0 kg of biodiesel, 25.0 kg of polyether and 25.0 kg of ester base oil, stir and heat to 50-60 ° C, add Span-80 sorbitan oil 10.0 kg of acid ester, 12.0 kg of EL-40 polyoxyethylene castor oil, 2.5 kg of extreme pressure antiwear agent, stirred for 1 hour, finally added 0.5 kg of defoamer, and continued to stir for 1 hour to obtain light yellow viscous liquid, namely The drilling fluid lubricant provided by the present invention.

Embodiment 2

[0015] Example 2: In a heated and stirred reactor, first add 20.0 kg of biodiesel, 30.0 kg of polyether and 30.0 kg of ester base oil, stir and heat to 50-60 °C, add Span-80 sorbitan oil 8.0 kg of acid ester, 10 kg of EL-40 polyoxyethylene castor oil, 1.5 kg of extreme pressure antiwear agent, stirred for 1 hour, finally added 0.5 kg of defoamer, and continued to stir for 1 hour to obtain light yellow viscous liquid, namely The drilling fluid lubricant provided by the present invention.

[0016] Biodiesel (20-30%), polyether (20-30%), ester base oil (20-30%), Span-80 sorbitan oleate (5-20%), EL-40 poly Oxyethylene castor oil (5-20%), extreme pressure antiwear agent (2-10%), defoamer (0.5-1%),

Embodiment 3

[0017] Example 3: In a heated and stirred reactor, first add 25.0 kg of biodiesel, 30.0 kg of polyether and 30.0 kg of ester base oil, stir and heat to 50-60°C, add Span-80 sorbitan oil 8.0 kg of acid ester, 5.0 kg of EL-40 polyoxyethylene castor oil, 1.5 kg of extreme pressure antiwear agent, stirred for 1 hour, finally added 0.5 kg of defoamer, and continued to stir for 1 hour to obtain light yellow viscous liquid, namely The drilling fluid lubricant provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com