Amino acid surfactant-based transparent solid soap

A surfactant, transparent solid technology, applied in the direction of non-ionic surface active compounds, detergent compounding agents, detergent compositions, etc., can solve the problems of insufficient foam, high irritation, not durable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

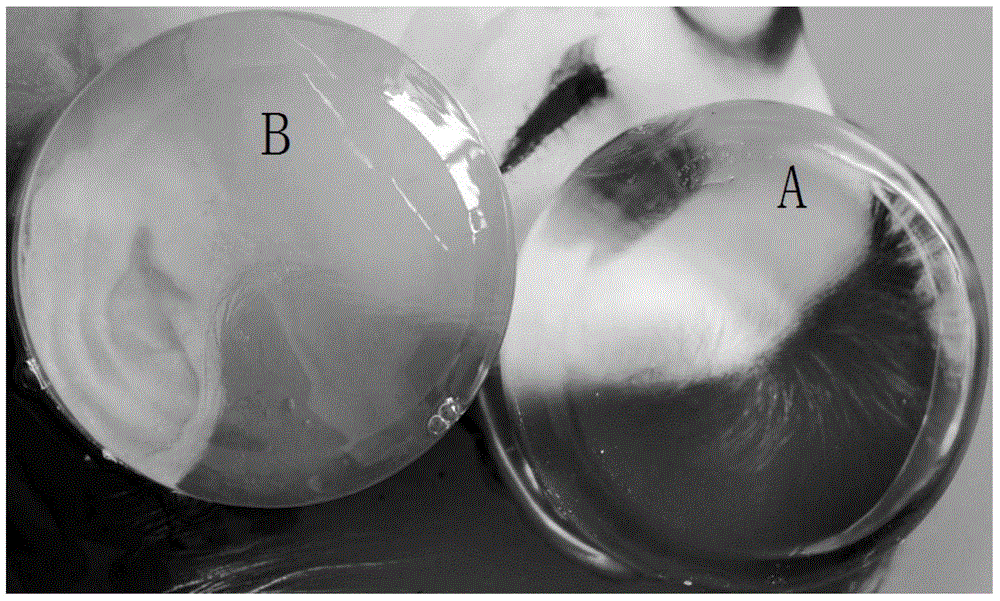

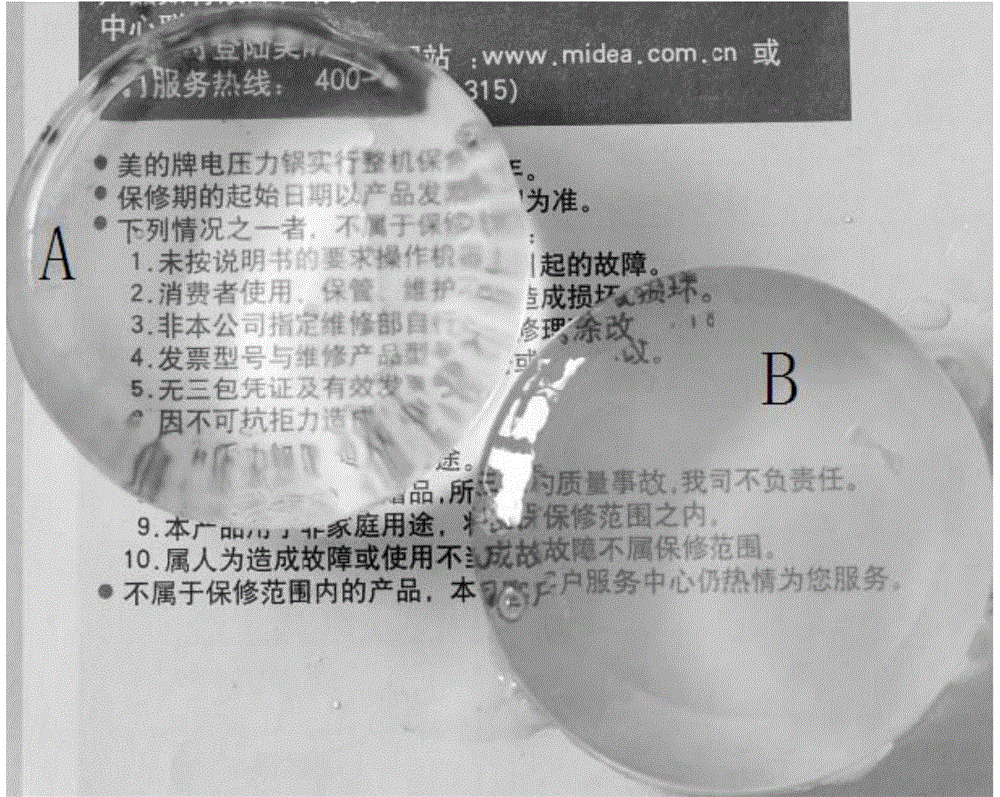

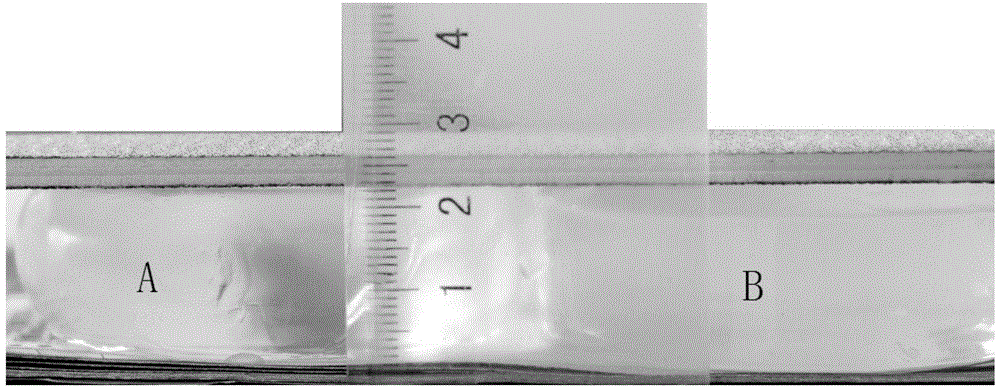

Image

Examples

Embodiment 1

[0024] 1. Raw material composition:

[0025] Coco triethanolamine glutamate 30 parts, sodium palmitoyl glutamate 20 parts, coco propyl glutamate 15 parts, pure water 13 parts, castor oil polyoxyethylene ether 8 parts, glycerin 5 parts , 5 parts of glucose, 2 parts of ethanol, 0.4 parts of PH balance agent, and 0.3 parts of essence.

[0026] 2. Preparation:

[0027] Add amino acid surfactants, additives and water into the mixing vessel according to the above raw material composition and ratio, heat to 75°C, stir until completely dissolved, then lower the temperature of the mixture to 50°C, and then go through defoaming, injection molding, and cooling in sequence , demoulding, air-drying, packaging to obtain the transparent solid soap of amino acid surfactant matrix.

Embodiment 2

[0029] 1. Raw material composition:

[0030] Sodium palmitoyl glutamate 30 parts, disodium cocoyl glutamate 11 parts, sodium cocoyl glutamate 20 parts, N-myristyl-L-glutamic acid dibutyramide 10 parts, purified water 10 parts 10 parts of castor oil polyoxyethylene ether, 3 parts of glycerin, 3 parts of glucose, 5 parts of ethanol, 0.2 parts of pH balance agent, and 0.5 parts of essence.

[0031] 2. Preparation:

[0032] Add amino acid surfactants, additives and water into the mixing vessel according to the above raw material composition and ratio, heat to 85°C, stir until completely dissolved, then lower the temperature of the mixture to 60°C, and then go through defoaming, injection molding, and cooling in sequence , demoulding, air-drying, packaging to obtain the transparent solid soap of amino acid surfactant matrix.

Embodiment 3

[0034] 1. Raw material composition:

[0035] 20 parts of sodium cocoyl glutamate, 20 parts of N-myristyl-L-glutamic acid dibutyramide, 15 parts of sodium octadecyl dimethylene carbamate, 3 parts of pure water, castor oil polyoxygen 3 parts of vinyl ether, 5 parts of glycerin, 10 parts of glucose, 5 parts of ethanol, 0.1 part of pH balance agent, 0.4 part of essence, 0.5 part of essential oil.

[0036] 2. Preparation:

[0037] Add amino acid surfactants, additives and water into the mixing vessel according to the above raw material composition and ratio, heat to 80°C, stir until completely dissolved, then lower the temperature of the mixture to 55°C, and then go through defoaming, injection molding, and cooling in sequence , demolding, air-drying, and packaging to obtain the transparent solid soap of the amino acid surfactant matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com