Method for measuring acid values of oil and products by using greening solvent based on potential jump

A green, petroleum acid technology, which is applied in chemical analysis by titration, analysis by chemical reaction of materials, and material analysis by observing the influence of chemical indicators, which can solve the problem of large error in results and lack of data. Comparability, difficulty in parallel and other problems, to achieve the effect of strong alkalinity, simple standard method, and elimination of limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

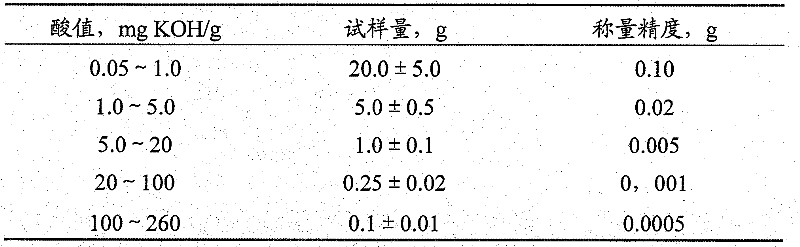

[0064] 1. Carry out a blank experiment first, take 90 mL of a 1:1 (vol.%) isooctane-isopropanol mixed solvent containing 0.05 mol / L methyldiethanolamine in a 150 mL dry beaker, and the titrant is 0.04952 mol / L Put the tetramethylammonium hydroxide (TMAH) standard solution into the titration stand of the potentiometric titrator, turn on the stirrer, set the appropriate titration parameters, start the "start" titration, and obtain the blank volume average value V through the potential jump. 0 is 0.135 mL. Then weigh 1.532g of old lubricating oil in a 150mL dry beaker, weighing to 0.001g, add 1:1 (vol.%) isooctane-isopropanol mixed solvent containing 0.05mol / L methyldiethanolamine 90mL, put it into the titration stand of potentiometric titrator, turn on the stirrer, set the appropriate titration parameters, start the "start" titration, automatically find the end point according to the potential jump, and consume 0.04952mol / L TMAH standard solution 0.751mL. Total acid value (AN) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com