A kind of anti-ultraviolet and light-resistant finishing liquid and its preparation and application on fabrics

A technology of anti-ultraviolet and finishing liquid, applied in fiber processing, textile and papermaking, dyeing and other directions, can solve the problems of high energy consumption and long process flow, and achieve the effect of short process flow and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

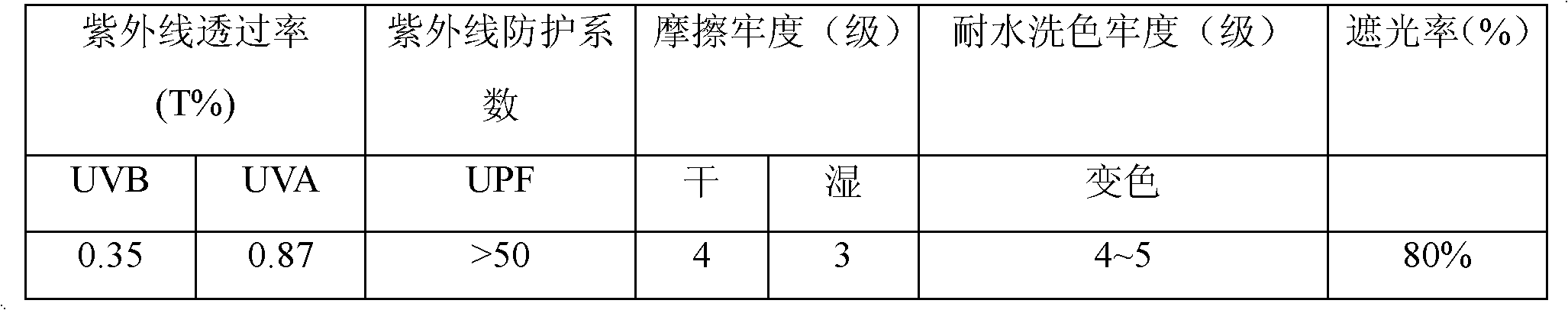

Embodiment 1

[0040] A kind of anti-ultraviolet, light fast finishing liquid, the formula of this finishing liquid comprises:

[0041] Paint 40g / L, paint white FTW 4g / L, acrylate adhesive 20g / L, urea 10g / L, glycerin 2g / L, silicone softener SPD 60g / L, micronano ZnO 2 7.5g / L, ZrO 2.5g / L, castor oil polyoxyethylene ether 5g / L, penetrant JFC 0.5~1g / L, solvent is water.

[0042] Its preparation includes:

[0043] Configuration component A: add water to paint, paint white FTW, stir at high speed to disperse, then add acrylate adhesive, urea, glycerin and silicone softener SPD in sequence, and stir evenly; the concentration of the paint is 40g / L, the paint The concentration of white FTW is 4g / L, the concentration of acrylate adhesive is 20g / L, the concentration of urea is 10g / L, the concentration of glycerin is 2g / L, and the concentration of silicone softener SPD is 60g / L;

[0044] Configuration component B: micro-nano ZnO 2 , ZrO 2.5g / L and castor oil polyoxyethylene ether are added to water,...

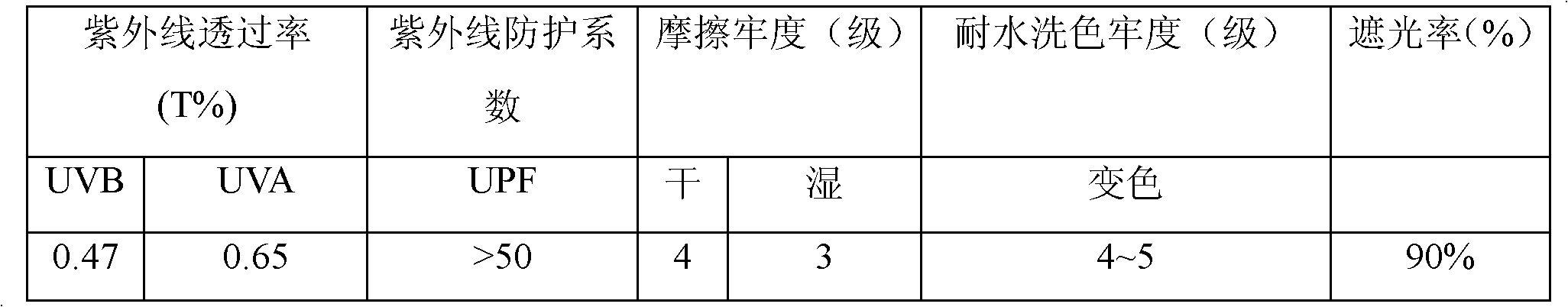

Embodiment 2

[0051] A kind of anti-ultraviolet, light fast finishing liquid, the formula of this finishing liquid comprises:

[0052] Paint 50g / L, paint white FTW 3g / L, acrylate adhesive 30g / L, urea 20g / L, glycerin 2g / L, silicone softener SPD 80g / L, micronano SiO 2 10g / L, carbon black 1g / L castor oil polyoxyethylene ether 3g / L, penetrant JFC 0.5~1g / L, solvent is water.

[0053] Its preparation includes:

[0054] Configuration component A: add water to paint, paint white FTW, stir at high speed to disperse, then add acrylate adhesive, urea, glycerin and silicone softener SPD in sequence, and stir evenly; the concentration of the paint is 50g / L, the paint The concentration of white FTW is 3g / L, the concentration of acrylate adhesive is 30g / L, the concentration of urea is 20g / L, the concentration of glycerin is 2g / L, and the concentration of silicone softener SPD is 80g / L;

[0055] Configuration component B: micro-nano SiO 2 , carbon black and castor oil polyoxyethylene ether are added to...

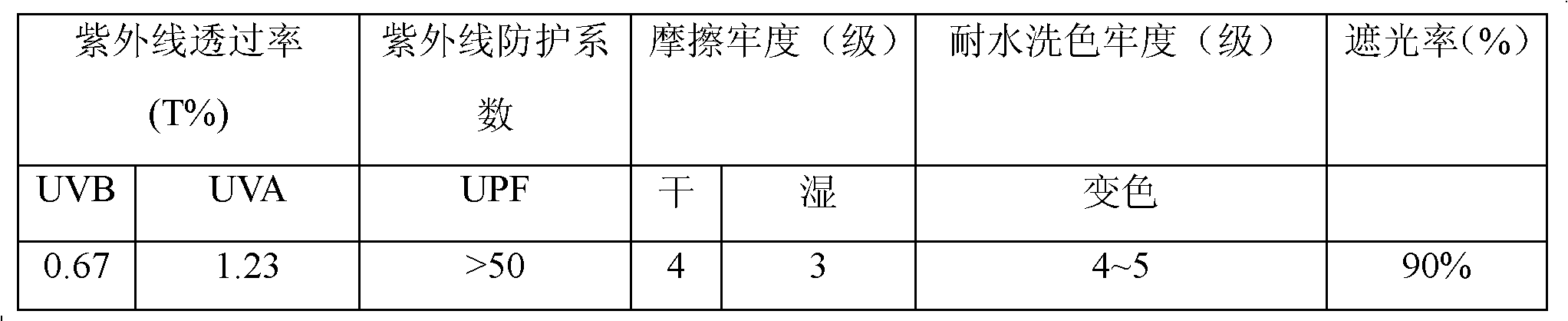

Embodiment 3

[0062] A kind of anti-ultraviolet, light fast finishing liquid, the formula of this finishing liquid comprises:

[0063] Paint 50g / L, paint white FTW 2g / L, acrylate adhesive 20g / L, urea 10g / L, glycerin 2g / L, silicone softener SPD 55g / L, micronano TiO 2 7.5g / L, carbon black 1.5g / L, castor oil polyoxyethylene ether 4g / L, penetrant JFC 0.5~1g / L, solvent is water.

[0064] Its preparation includes:

[0065] Configuration component A: add water to paint, paint white FTW, stir at high speed to disperse, then add acrylate adhesive, urea and glycerin, silicone softener SPD, and stir evenly; the concentration of paint is 50g / L, paint The concentration of white FTW is 2g / L, the concentration of acrylate adhesive is 20g / L, the concentration of urea is 10g / L, the concentration of glycerin is 2g / L, and the concentration of silicone softener SPD is 55g / L;

[0066] Configuration component B: add micronano, carbon black and castor oil polyoxyethylene ether into water, stir at high speed; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com