Developing solution as well as preparation method and application thereof

A developing solution and compound technology, applied in the field of developing solution and its preparation, can solve the problems of reducing the yield rate of panel production lines, affecting the display quality of flat panel display images, etc., and achieve the effects of wide operating temperature range, less environmental pollution, and good developing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

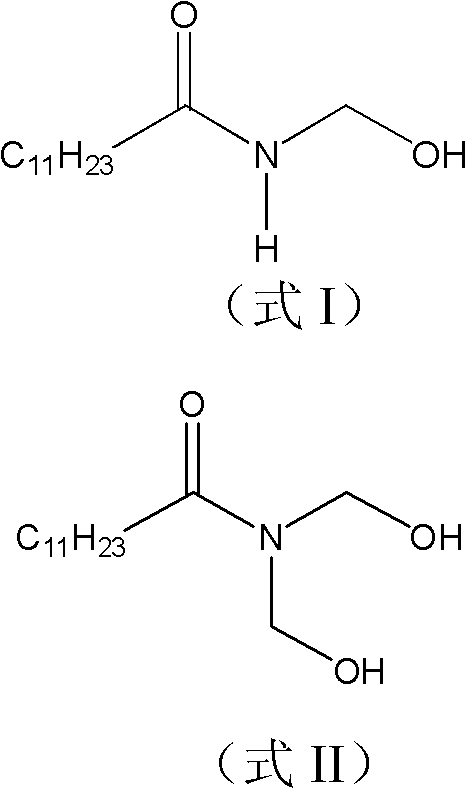

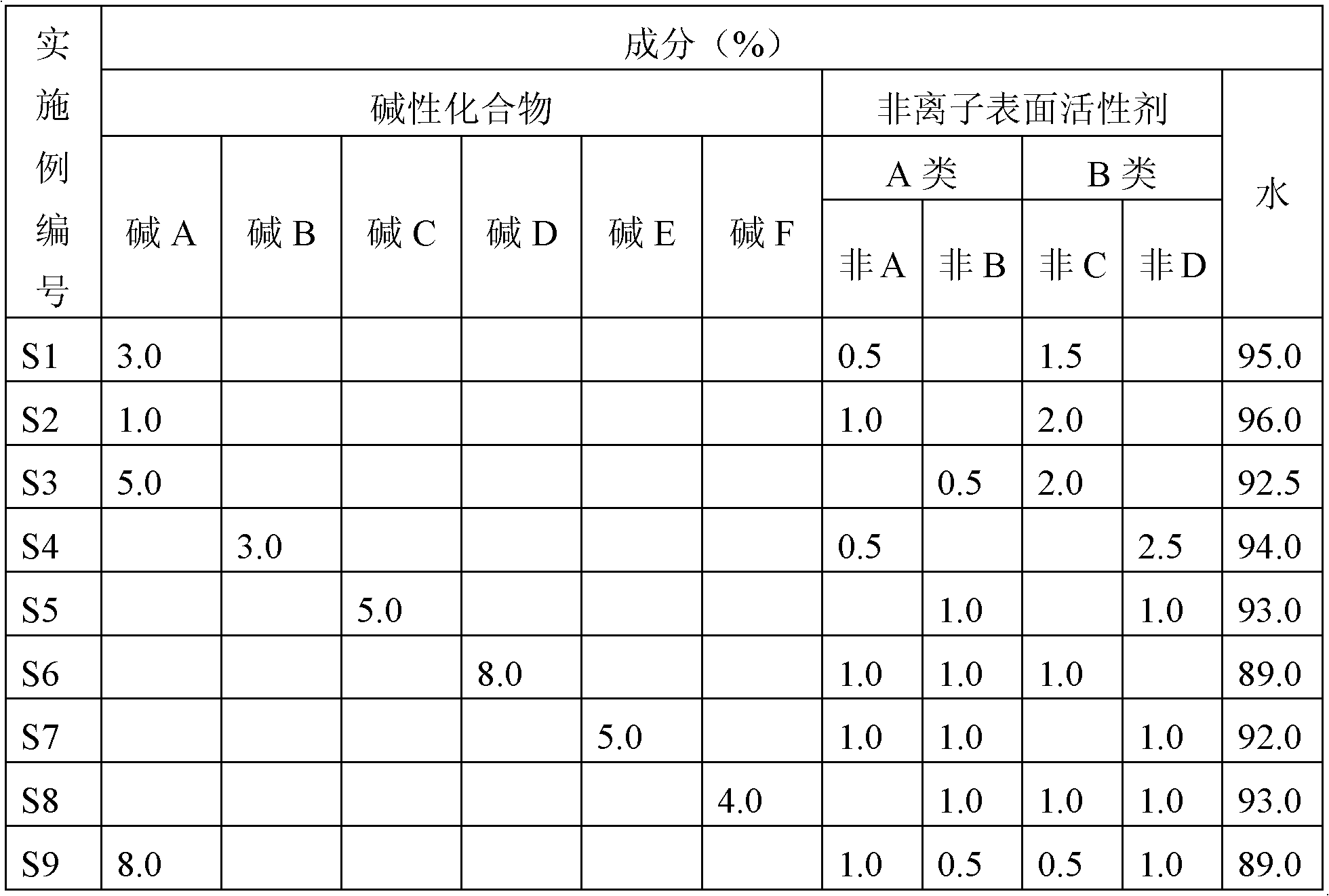

[0042] Will be by the nonionic surfactant coconut oil fatty acid monoethanolamide (commercial name CMEA) shown in 0.5 weight part formula I and 1.5 weight part nonionic surfactant castor oil polyoxyethylene (10) ether (trade name EL-10) With 3.0 parts by weight of tetramethylammonium hydroxide added to 95.0 parts by weight of the total metal ion concentration is 400 × 10 -9 g / g of deionized water was stirred evenly at room temperature to obtain the developer solution 1 provided by the present invention.

Embodiment 2-18

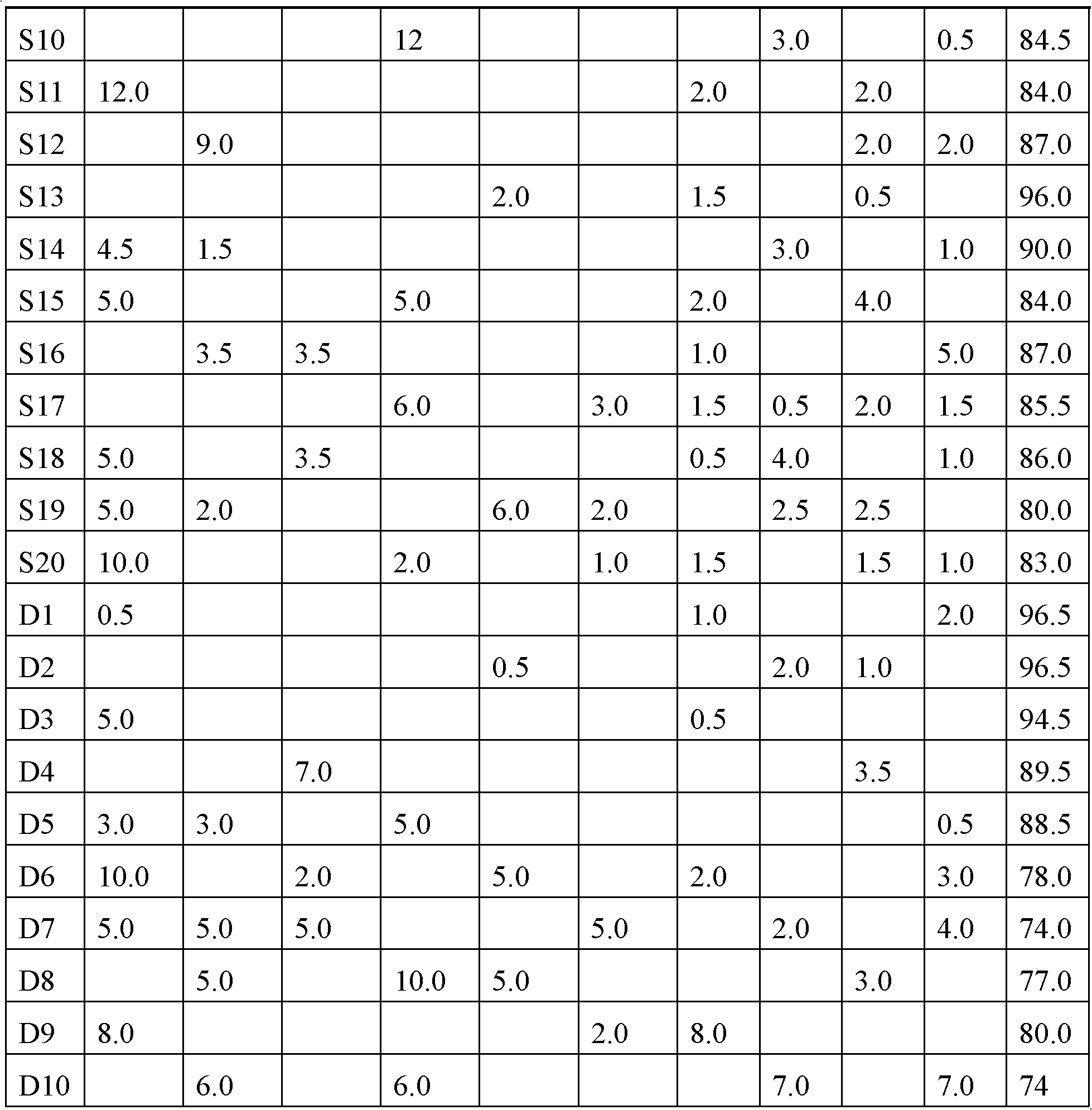

[0043] Embodiment 2-18 (S2-S20)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com