Collagen/polyvinyl alcohol composite microspheres as well as preparation method and application thereof

A technology of collagen and polyvinyl alcohol, applied in the direction of animal/human protein, conjugated synthetic polymer artificial filament, cellulose/protein conjugated artificial filament, etc., can solve the problems that cannot meet the wide range of needs and applications of biomedical materials Single field and other problems, to achieve the effect of facilitating migration and proliferation, improving therapeutic effect, and good gel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

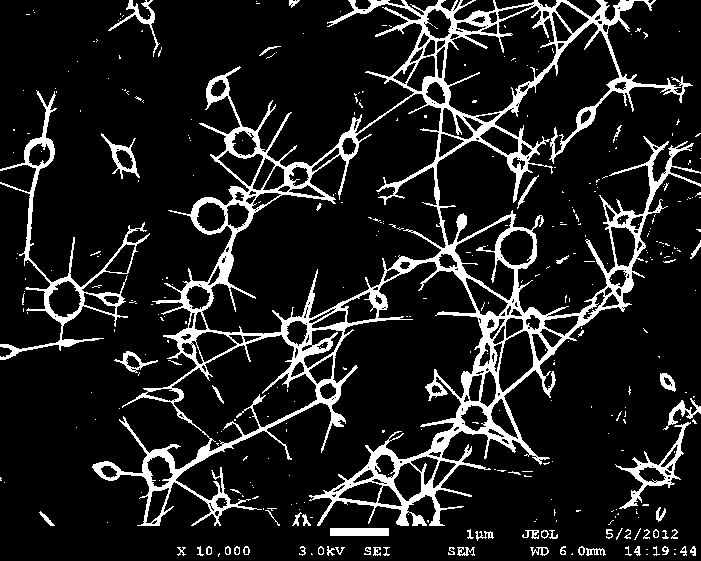

[0019] Collagen / polyvinyl alcohol composite microspheres are composite systems composed of collagen / polyvinyl alcohol microspheres and collagen / polyvinyl alcohol nanofibers, such as figure 1 As shown, the composite system uses microspheres as nodes and is connected into a beaded or net shape by nanofibers, wherein the average diameter of the microspheres is 550 nm, and the average diameter of the nanofibers is 55 nm.

[0020] The preparation method of the collagen / polyvinyl alcohol composite microspheres comprises the following steps:

[0021] 1) Collagen is extracted from pigskin by pepsin-acid hydrolysis, and then small-molecular-weight collagen is removed by cellulose dialysis membrane with a molecular weight cut-off of 8,000-14,400. The remaining collagen has a high molecular weight and narrow distribution, and is formed after freeze-drying Porous collagen sponge; at 15°C, take 0.5g of collagen sponge and dissolve it in 50mL of 0.5M acetic acid aqueous solution, stir until...

Embodiment 2

[0026] Collagen / polyvinyl alcohol composite microspheres are a composite system composed of collagen / polyvinyl alcohol microspheres and collagen / polyvinyl alcohol nanofibers. The composite system uses microspheres as nodes and is connected by nanofibers to form beads shape or network, wherein the diameter of microspheres is 100-1000nm, and the diameter of nanofibers is 1-100nm.

[0027] The preparation method of the collagen / polyvinyl alcohol composite microspheres comprises the following steps:

[0028] 1) Collagen is extracted from pigskin by pepsin-acid hydrolysis, and then small-molecular-weight collagen is removed by cellulose dialysis membrane with a molecular weight cut-off of 8,000-14,400. The remaining collagen has a high molecular weight and narrow distribution, and is formed after freeze-drying Porous collagen sponge; at 20°C, take 0.75g of collagen sponge and dissolve it in 50mL of 0.8M acetic acid aqueous solution, stir until completely dissolved, and prepare a co...

Embodiment 3

[0031] Collagen / polyvinyl alcohol composite microspheres are a composite system composed of collagen / polyvinyl alcohol microspheres and collagen / polyvinyl alcohol nanofibers. The composite system uses microspheres as nodes and is connected by nanofibers to form beads shape or network, wherein the diameter of microspheres is 100-1000nm, and the diameter of nanofibers is 1-100nm.

[0032] The preparation method of the collagen / polyvinyl alcohol composite microspheres comprises the following steps:

[0033] 1) Collagen is extracted from pigskin by pepsin-acid hydrolysis, and then small-molecular-weight collagen is removed by cellulose dialysis membrane with a molecular weight cut-off of 8,000-14,400. The remaining collagen has a high molecular weight and narrow distribution, and is formed after freeze-drying Porous collagen sponge; at 30°C, take 0.35g of collagen sponge and dissolve it in 50mL of 0.5M acetic acid aqueous solution, stir until completely dissolved, and prepare a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com