Hydrate inhibitor polymer and preparation method

A hydrate inhibitor and polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost, and achieve the effects of improving temperature resistance, strong adsorption, and simple and feasible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

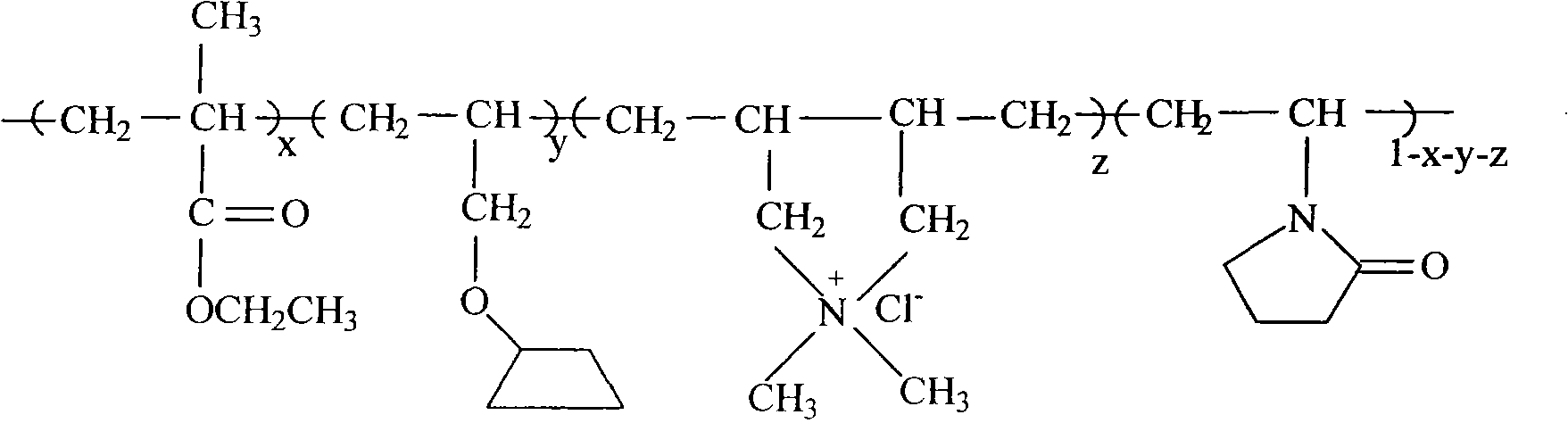

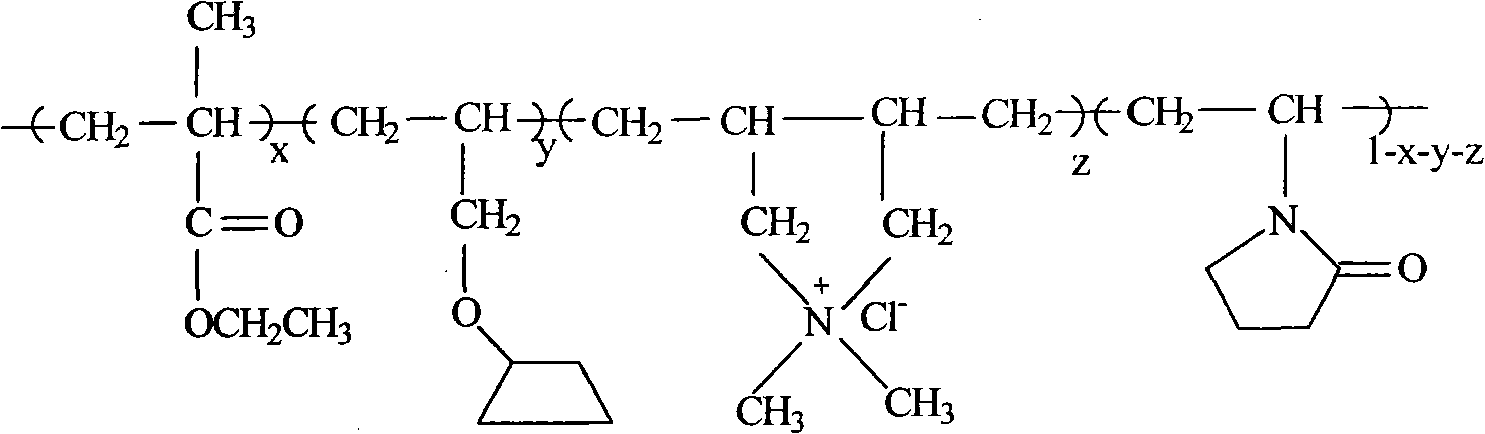

Image

Examples

Embodiment 1

[0017] The preparation method of embodiment 1EM / ACD / DMDAAC / NVP polymer

[0018] Take 0.5g / mL dimethyl diallyl ammonium chloride (DMDAAC) aqueous solution 3.8mL in a 150mL beaker, accurately add 1.2g ethyl methacrylate (EM) under magnetic stirring, and then stir at high speed for 10-20min Make it a lotion.

[0019] The above emulsion and 5 mL of NVP aqueous solution with a concentration of 0.5 g / mL were added to 50 mL of an allyl β-cyclodextrin (ACD) aqueous solution with a concentration of 0.01 g / mL. Then add 0.6 g disodium ethylenediaminetetraacetic acid (EDTA) chelating agent, 0.6 g potassium persulfate oxidizing agent and 0.6 g sodium bisulfite reducing agent in sequence. Fully stir and mix evenly on a magnetic stirrer, fill with nitrogen for 40 minutes to remove oxygen, and react at 50°C for 9 hours to obtain EM / ACD / DMDAAC / NVP tetrapolymer.

[0020] Measure the intrinsic viscosity number of EM / ACD / DMDAAC / NVP polymer according to the standard described in GB12005.1-89, an...

Embodiment 2

[0021] Hydrate inhibition effect of embodiment 2EM / ACD / DMDAAC / NVP polymer in drilling fluid

[0022] In order to evaluate the hydrate inhibition effect of EM / ACD / DMDAAC / NVP polymer in drilling fluid, a visual high-pressure fluid test system was used. The system consists of an autoclave with sapphire double windows, a constant temperature bath, a temperature control system, a pressure control system and a measurement system.

[0023] Although the generation of hydrate can be observed through the window, the present invention uses the sudden change of pressure and temperature in the kettle to judge. Because the hydrate formation reaction is an exothermic reaction, the temperature will increase and the pressure will drop significantly at the same time. The hydrate formation time determined by the experiment is the time from the pressure drop point to the pressure drop point when gas is introduced into the kettle and the pressure is constant at 16Mpa.

[0024] The evaluation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com