Preparation method and application of bowl-like nitrogen-doped carbon hollow particle

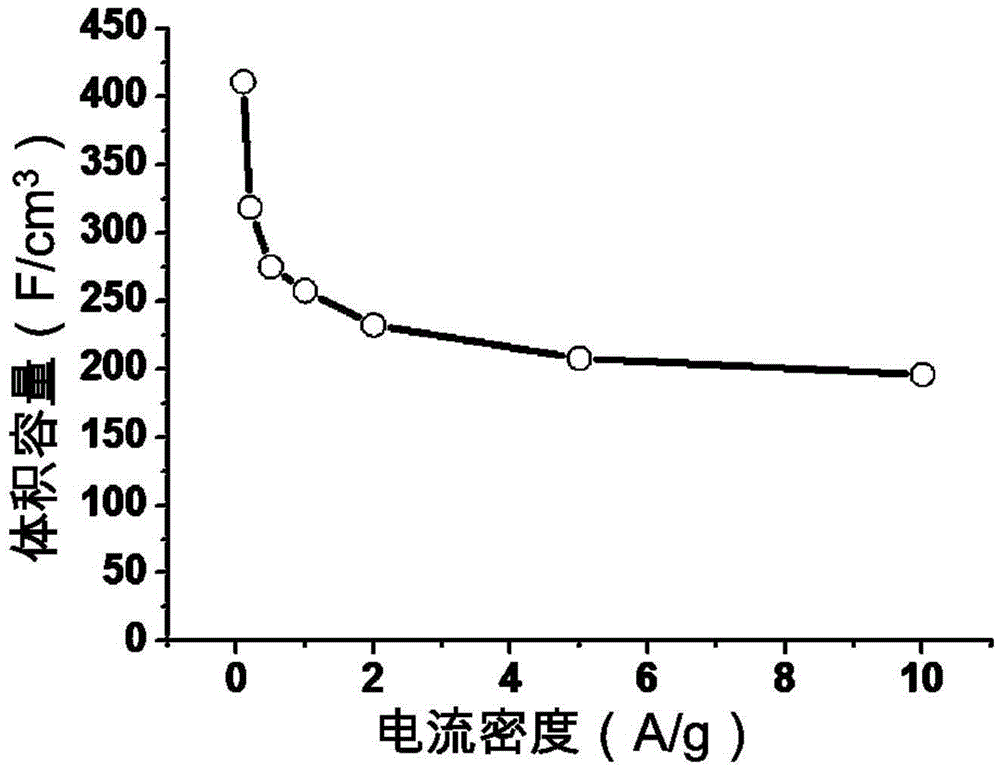

A nitrogen-doped carbon, bowl-shaped technology is applied in the field of preparation of bowl-shaped nitrogen-doped carbon hollow particles, which can solve the problems of low success rate, large influence of environmental factors, high preparation cost, and achieve high capacity retention rate and stable cycle. performance, simple and feasible preparation method, high success rate and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 of the present invention provides a method for preparing bowl-shaped nitrogen-doped carbon hollow particles, including the following steps:

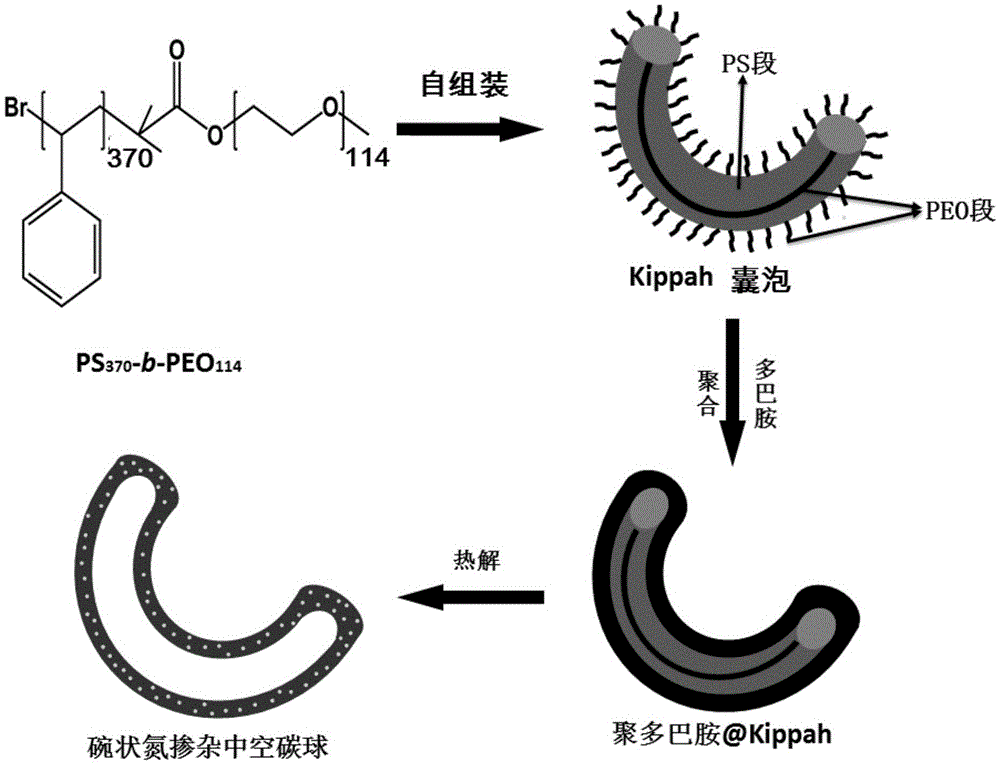

[0029] Step 1: Add deionized water (or ultrapure water) to 1-4ml dioxane solution in which 10-20mg of amphiphilic PS-b-PEO block copolymer is dissolved, and PS-b-PEO is embedded The segment copolymer self-assembles to form vesicles in the dioxane solution. When the amount of deionized water added reaches the total mass of the solution (that is, the total mass of PS-b-PEO block copolymer + dioxane solution + deionized water) ), quickly add more than 10 times the amount of deionized water previously added to collapse the vesicles formed by the self-assembly of the PS-b-PEO block copolymer in the dioxane solution to obtain a bowl-shaped vesicle Vesicles, Kippah vesicles.

[0030] Step 2: Use the Kippah vesicles obtained in Step 1 as a template to support the polymerization of dopamine on PEO segments to obtain bowl-shaped po...

Embodiment 2

[0036] Embodiment 2 of the present invention provides a method for preparing bowl-shaped nitrogen-doped carbon hollow particles, including the following steps:

[0037] Step one, take 10~20mgPS 370 -B-PEO 114 The block copolymer was dissolved in 1 mL of dioxane solution. After magnetic stirring at room temperature for 1 hour, 1 mL of ultrapure water was added, and then 20 mL of ultrapure water was quickly added to obtain bowl-shaped vesicles, namely Kippah vesicles;

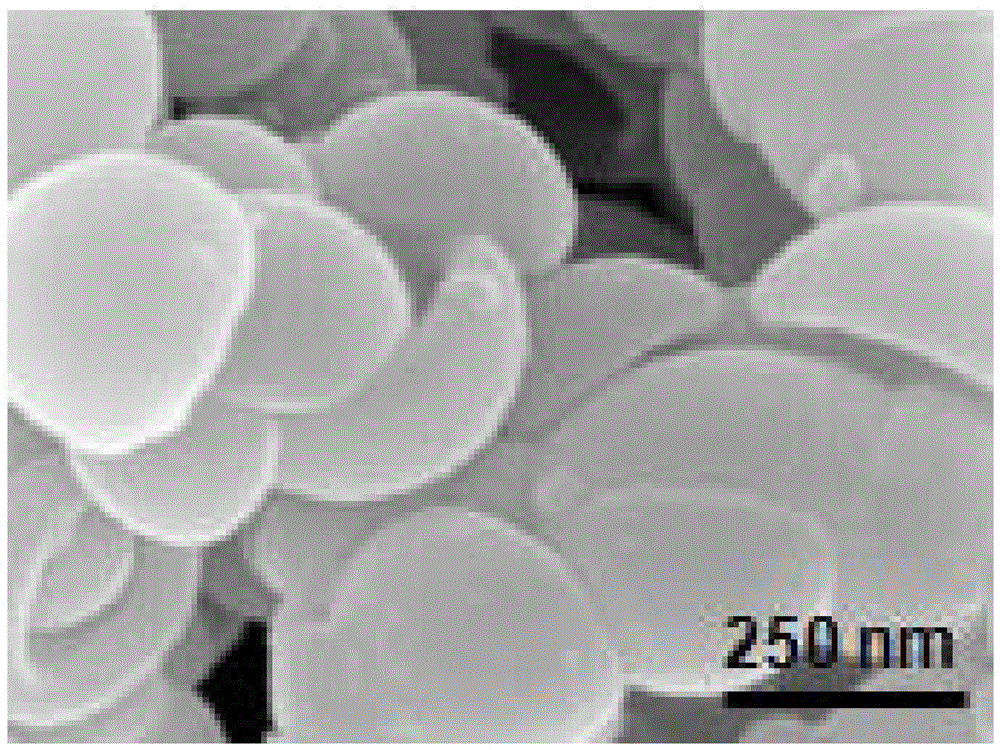

[0038] Step 2: Use the Kippah vesicles obtained in Step 1 as a template to support the polymerization of dopamine on PEO segments to obtain bowl-shaped polydopamine Kippah particles; specifically, add 20 mg of dopamine to the solution containing Kippah vesicles obtained in Step 1 to obtain The mixture was gently stirred at room temperature for 1h, and then 20mg of tris(hydroxymethylaminomethane) hydrochloride was added and reacted for 48h at room temperature to polymerize dopamine. The product obtained after polymeriza...

Embodiment 3

[0041] Embodiment 3 of the present invention provides a method for preparing bowl-shaped nitrogen-doped carbon hollow particles, including the following steps:

[0042] Step one, take 10~20mgPS 370 -B-PEO 114 The block copolymer was dissolved in 4 mL of dioxane solution, and after magnetic stirring at room temperature for 1 hour, 1 mL of ultrapure water was added, and then 20 mL of ultrapure water was quickly added to obtain bowl-shaped vesicles, namely Kippah vesicles;

[0043] Step 2: Use the Kippah vesicles obtained in Step 1 as a template to support the polymerization of dopamine on PEO segments to obtain bowl-shaped polydopamine Kippah particles; specifically, add 10 mg of dopamine to the solution containing Kippah vesicles obtained in Step 1, to obtain The mixture was gently stirred at room temperature for 2h, and then 20mg of tris(hydroxymethylaminomethane) hydrochloride was added and reacted for 48h at room temperature to polymerize dopamine. The product obtained after polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com