Preparation methods for organic-inorganic hybridized perovskite quantum dots and thin film

A technology of perovskite and quantum dots, which is applied in the field of preparation of luminescent materials, can solve the problems of low luminous efficiency of quantum dots, achieve high luminous efficiency, simple and feasible preparation method, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

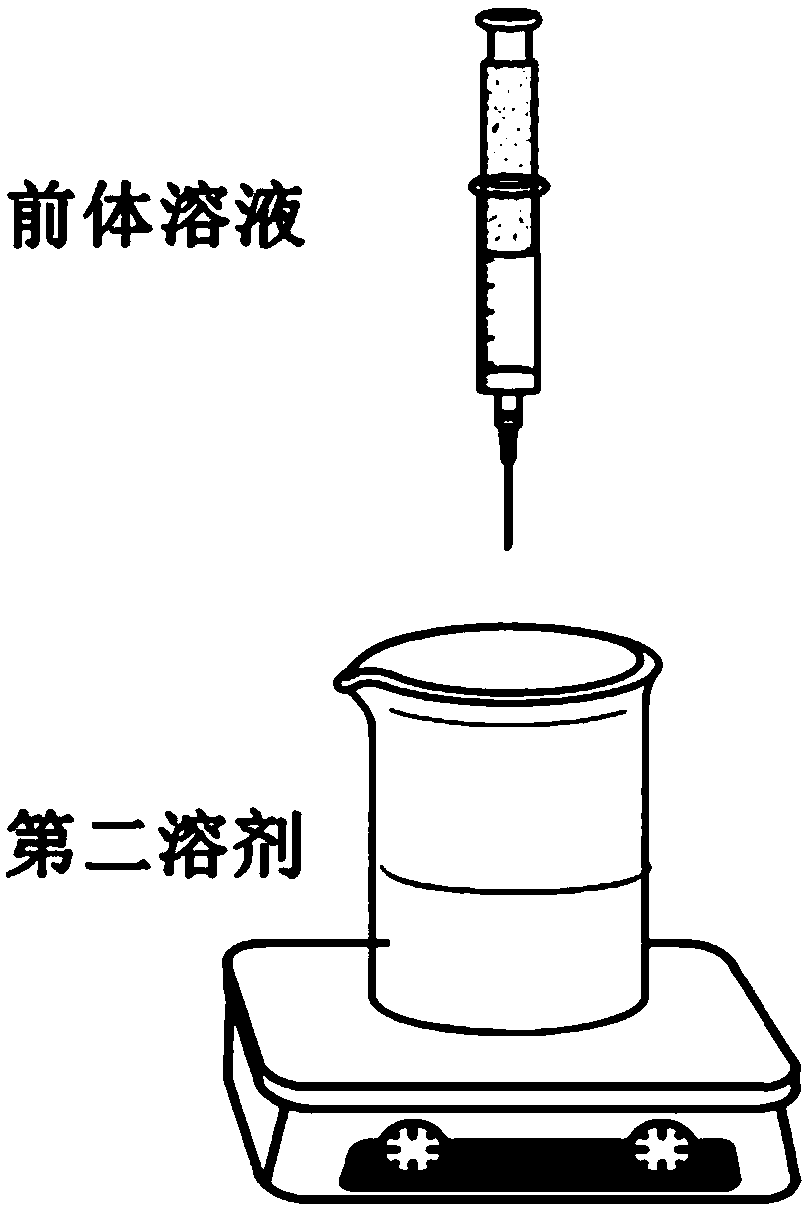

Method used

Image

Examples

Embodiment 1

[0045] This example uses butylamine hydrobromic acid as a surface coating agent to prepare CH 3 NH 3 PbBr 3 Quantum dots, the specific steps are:

[0046] 1. Preparation of methylamine bromide

[0047]Drop 5mL of methylamine ethanol solution with a mass fraction of 40% (purity>99.9%) into a beaker containing 20mL of ethanol solution, stir for 10 minutes until uniform, and add to the above solution while stirring in an ice-water bath environment Mass fraction is 5mL of hydrobromic acid of 49%, under ice-water bath environment, continue to stir 0.5 hour, obtain clear solution; Then continue to stir 3h on the heating stirring table of 50 degrees Celsius, remove solvent; Wash with water and ether three times, filter with suction, and dry in a vacuum oven at room temperature under a pressure of -0.1MPa for 4 hours to obtain methylamine bromide powder;

[0048] 2. Preparation of butylamine hydrobromide

[0049] Drop 5mL of butylamine (purity>99.9%) into a beaker containing 20mL...

Embodiment 2

[0057] This example uses propylamine hydrochloric acid as the surface coating agent to prepare CH 3 NH 3 PbCl 3 Quantum dots, the specific steps are:

[0058] 1. Preparation of Methylamine Chloride

[0059] Drop 5mL of methylamine ethanol solution with a mass fraction of 40% (purity>99.9%) into a beaker containing 20mL of ethanol solution, stir for 10 minutes until uniform, and add to the above solution while stirring in an ice-water bath environment Concentrated hydrochloric acid 5mL with a mass fraction of 37% was continuously stirred for 2 hours in an ice-water bath environment to obtain a clear solution; then continued to stir for 3 hours on a heating and stirring table at 50 degrees to remove the solvent; the product remaining at the bottom of the beaker was washed with anhydrous Wash with diethyl ether three times, filter with suction, and dry in a vacuum oven at room temperature under a pressure of -0.1MPa for 4 hours to obtain methylamine chloride powder;

[0060] ...

Embodiment 3

[0069] This example uses ethylamine hydrobromic acid as a surface coating agent to prepare CH 3 NH 2 SnBr 3 Quantum dots, the specific steps are:

[0070] 1. Preparation of methylamine bromide

[0071] The preparation method of methylamine bromide is described with embodiment 2 step 1;

[0072] 2. Preparation of ethylamine hydrobromide

[0073] Drop 5 mL of ethylamine solution (purity >99.9%) with a mass fraction of 70% into a beaker containing 20 mL of ethanol solution, stir for 10 minutes until uniform, and add mass to the above solution while stirring in an ice-water bath environment. Fraction is 49% hydrobromic acid 7mL, under ice-water bath environment, continue to stir for 0.5 hour, obtain clear solution; Continue to stir 3h on the heating stirring platform of 50 degree then, remove solvent; Wash with diethyl ether three times, filter with suction, and dry in a vacuum oven at room temperature under a pressure of -0.1MPa for 4 hours to obtain ethylamine hydrobromic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com