Portable hand tool carrier harness

a hand tool and harness technology, applied in the field of portable hand tool carriers, can solve the problems of constant frustration, cordless drills falling off the ladder, breaking or damage something or hurting someone below, and dropping cordless drills often breaking and ceased to function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

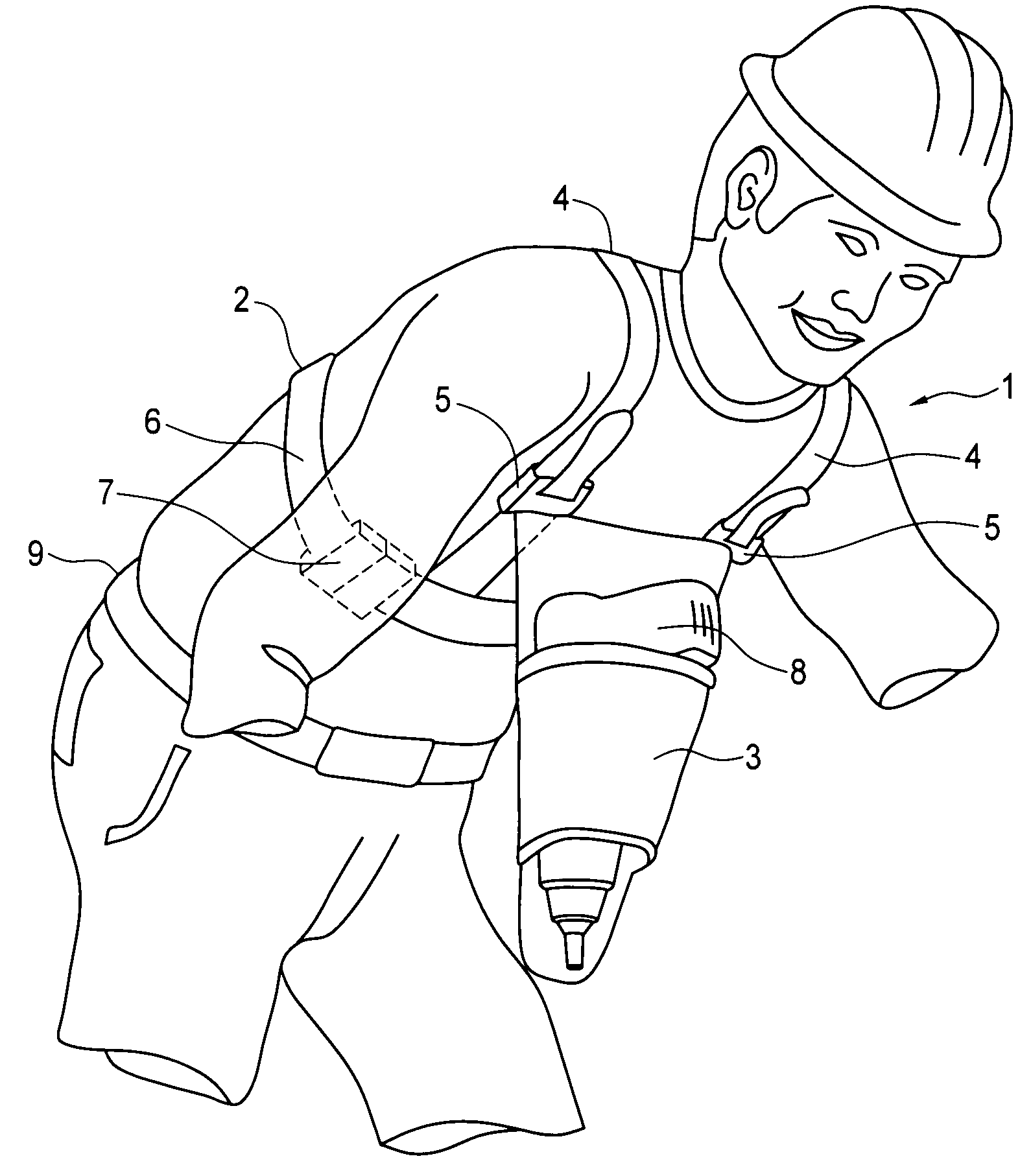

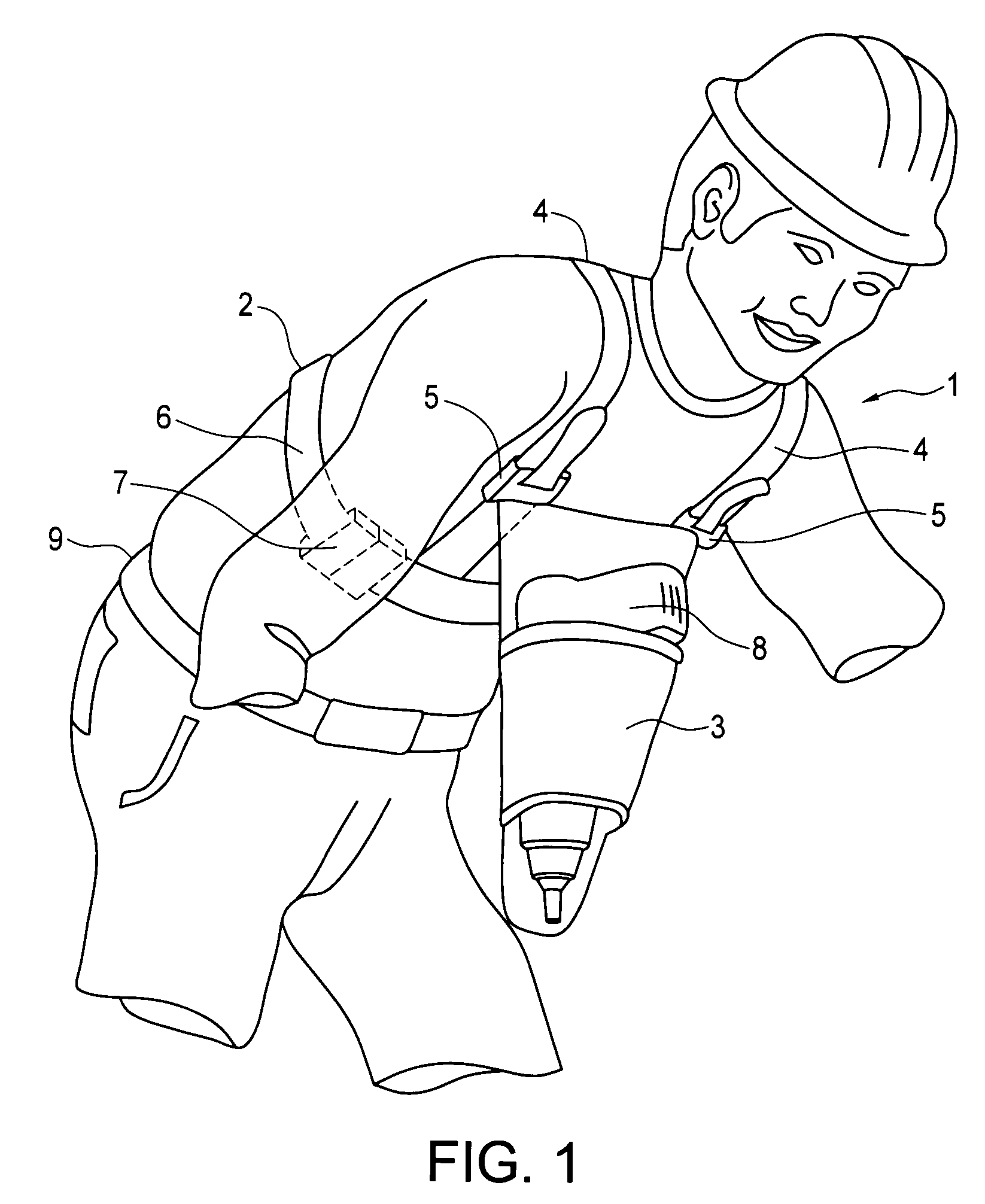

[0040]FIG. 1 illustrates a front perspective view of a worker bending forward and wearing a portable hand drill carrier holster according to the invention. As seen in FIG. 1, the worker 1 is wearing a chest harness 2 which comprises a pair of adjustable length shoulder straps 4 and an adjustable width chest strap 6. The pair of shoulder straps 4 have a respective pair of slide fasteners 5 mounted on the front of each of the two shoulder straps 4. Pivotally secured to the pair of slide fasteners 5 is a holster 3 which holds a cordless drill 8. The chest strap 6 can be readily detached and released by a detachment buckle 7. As seen in FIG. 1, the holster 3, by being pivotally attached to the respective slide fasteners 5, rather than being secured snugly to the body of the worker, is encouraged by gravity to maintain a relatively vertical position. This action holds the cordless drill 8 in place within the holster 3. The points where the top two ends of the holster 3 are pivotally secu...

second embodiment

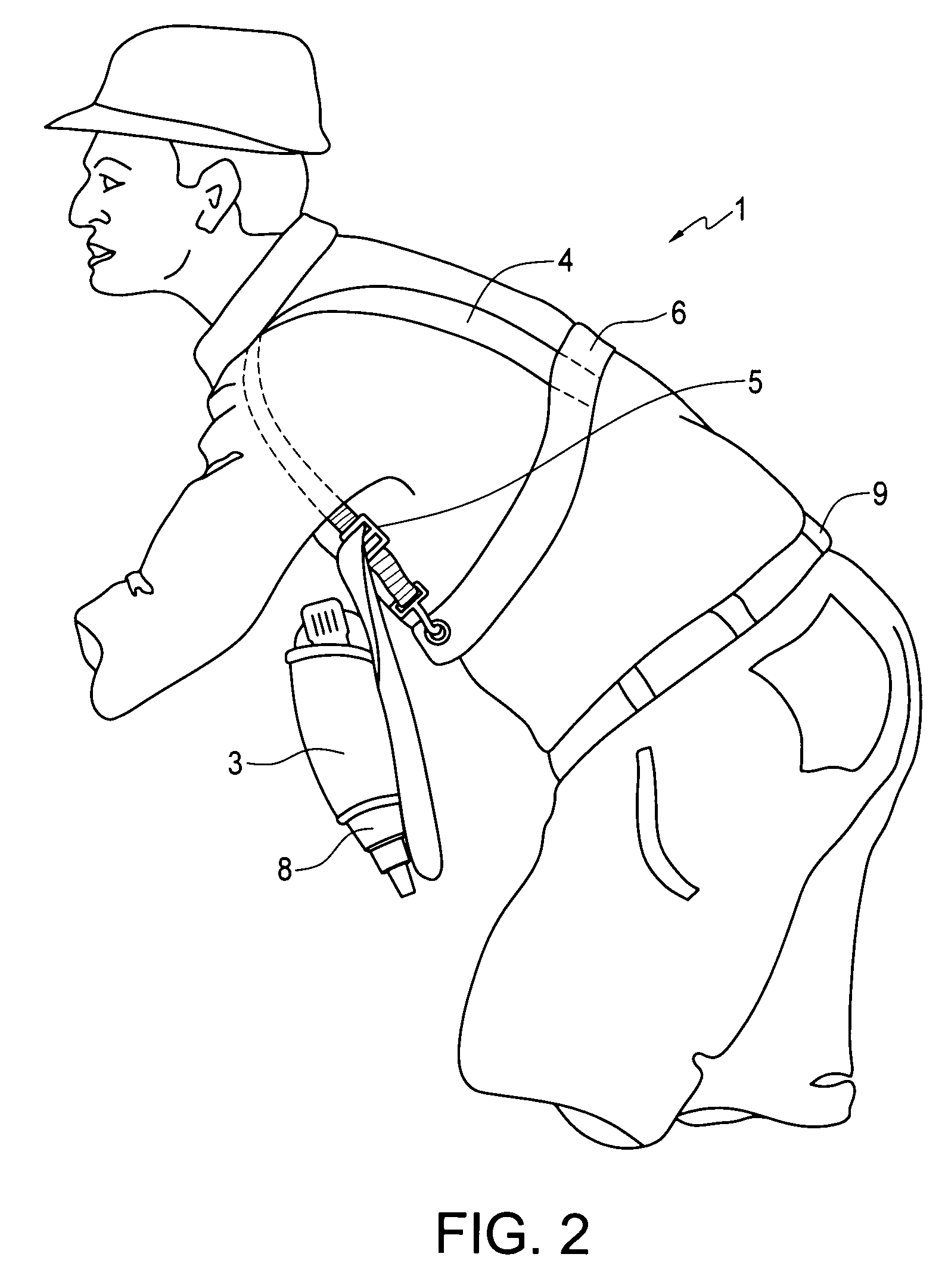

[0042]FIG. 3 shows a left side perspective view of a worker 14 bending forward while wearing a cordless drill carrier holster according to the invention. The ergonomic cordless drill carrier holster system 10 is constructed of a quick-draw drill carrier holster 16 which holds a cordless drill 12. The holster 16 is hingedly or pivotally connected to the central area of a chest, back and shoulder harness 30 at hinge point 46. The hinge point 46 should be at a reasonably high elevation to ensure that the holster 16 remains in a reasonably vertical position as the worker 14 moves about or bends over. In FIG. 3, it can be seen that the hinge point 46 is at the top rather than the bottom of the front chest position of the harness 30.

[0043]While not shown, the chest harness 30 can include a quick action separating buckle for a chest belt and length adjusters for the shoulder belts. It is understood that any suitable buckle or quick release fastening attachment or shoulder belt length adjus...

third embodiment

[0045]FIG. 4 shows an isometric view of the carrier holster system 10, wherein the quick-draw carrier holster 16 is releasably mounted onto the chest belt 40 by a belt loop 58, that is formed from an upward extension of the rear panel 24 of the holster 16. The belt loop 58 is affixed in a loop configuration by rivets or fasteners 60 or similar means of loop securement. FIG. 4 also shows elements of the quick-draw carrier holster 16, such as its front panel 18, top lip 20, which can be reinforced to withstand wear, side panel 22, rear panel 24, and chuck hole 26. The rim of the chuck hole 26 can be reinforced to withstand wear. The base of the rear panel 24 extends below the bottom hole 26 in the holster 16 and keeps the chuck of the drill 12 and any tool mounted in the chuck from rubbing on the clothing of the worker, or on other tools carried by the worker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com