Thermoplastic micro-foaming damping material and preparation method thereof

A shock-absorbing material and thermoplastic technology, applied in the field of polymer material processing, can solve the problems of poor flexibility and dynamic mechanical properties shock absorption, can not fully meet high-speed rail shock absorption, unstable mechanical properties and other problems, and achieve good interface compatibility. , Good performance, smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

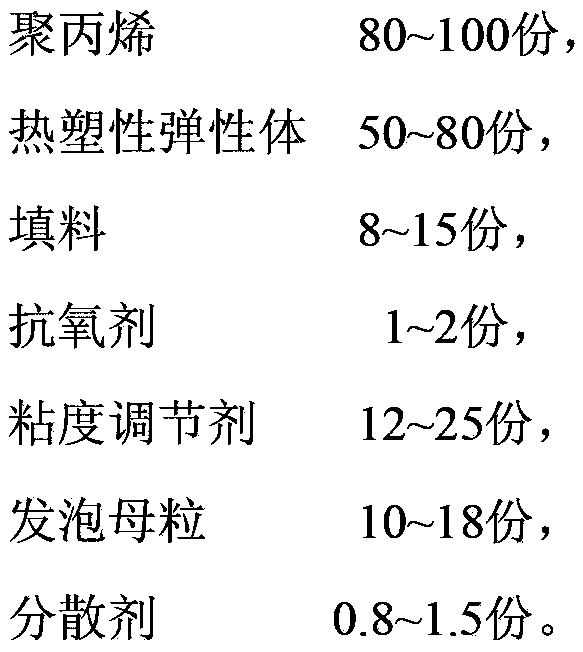

Method used

Image

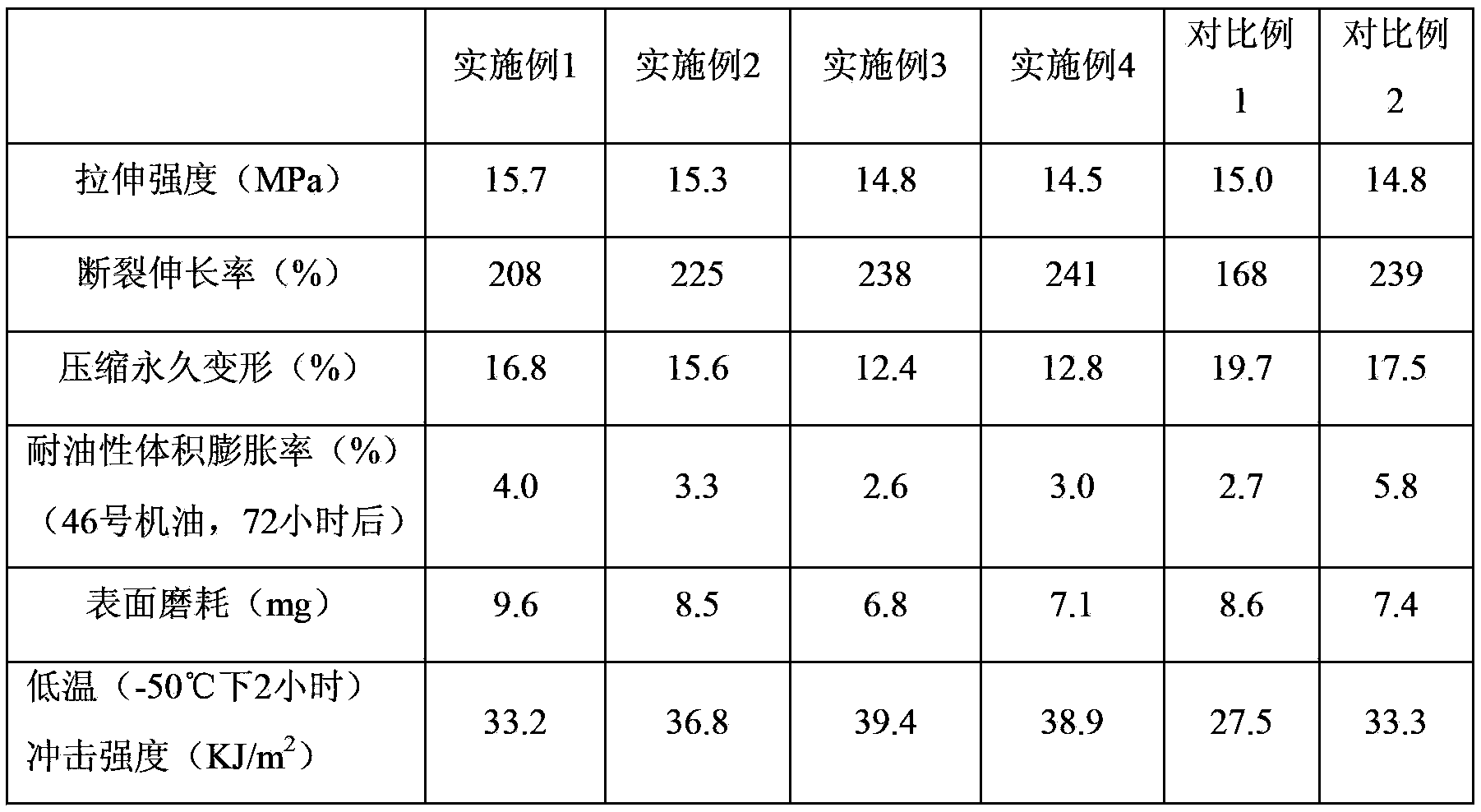

Examples

Embodiment 1

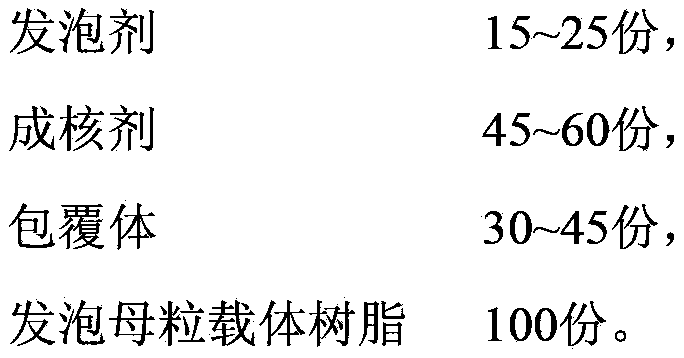

[0032] The preparation of thermoplastic micro-foaming shock-absorbing material in the present embodiment is as follows:

[0033] (1) Preparation of foam masterbatch: add 18 parts of azodicarbonamide, 50 parts of talc powder, 30 parts of ethylene-vinyl acetate copolymer, and 100 parts of low-density polyethylene into a high-speed mixer and mix well, then use a twin-screw extruder to Extrusion and granulation; the extrusion temperature is 140-145°C, and the screw speed is 40r / min;

[0034] (2) Preparation of base material: 100 parts of polypropylene, 50 parts of thermoplastic EPDM dynamically vulcanized elastomer (TPV), 15 parts of titanium dioxide, 1.2 parts of stearyl thiodipropionate, and 12 parts of low-density polyethylene , 1.3 parts of polyethylene wax were added to the mixer and mixed at high speed for 5 minutes, and then added to the twin-screw extruder for granulation; the speed was 210r / min, the temperature was set at 180-185°C, and the water-cooled strands were pelle...

Embodiment 2

[0038] The preparation of thermoplastic micro-foaming shock-absorbing material in the present embodiment is as follows:

[0039] (1) Preparation of foam masterbatch: add 15 parts of azodicarbonamide, 45 parts of talc powder, 35 parts of ethylene-vinyl acetate copolymer, and 100 parts of low-density polyethylene into a high-speed mixer and mix well, then use a twin-screw extruder to Extrusion and granulation; the extrusion temperature is 140-145°C, and the screw speed is 40r / min;

[0040] (2) Preparation of base material: 90 parts of polypropylene, 65 parts of thermoplastic styrene elastomer (TPS), 4 parts of mica and 4 parts of talcum powder, 4,4'-thio(6-tert-butyl-3- 1.0 parts of methyl phenol), 18 parts of ethylene-vinyl acetate copolymer, and 0.8 parts of stearic acid were added to the mixer and mixed at high speed for 8 minutes, and then added to the twin-screw extruder for granulation; the speed was 180r / min, and the temperature setting 185~190℃, the water-cooled strands...

Embodiment 3

[0044] The preparation of thermoplastic micro-foaming shock-absorbing material in the present embodiment is as follows:

[0045] (1) Preparation of foam masterbatch: add 20 parts of azodicarbonamide, 60 parts of talc powder, 45 parts of ethylene-vinyl acetate copolymer, and 100 parts of low-density polyethylene into a high-speed mixer and mix well, then use a twin-screw extruder to Extrusion and granulation; the extrusion temperature is 145-150°C, and the screw speed is 40r / min;

[0046](2) Preparation of base material: 80 parts of polypropylene, 70 parts of thermoplastic polyester elastomer (TPEE), 12 parts of titanium dioxide, [β-(3,5 di-tert-butyl 4-hydroxy-phenyl) propionic acid] 1.5 parts of pentaerythritol ester, 20 parts of ethylene-vinyl acetate copolymer, and 1.2 parts of polyethylene wax were added to the mixer and mixed at high speed for 6 minutes, and then added to the twin-screw extruder for granulation; the speed was 240r / min, and the temperature was set at 185 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com