Prefabricated constructional column used at exposed corner of wall and rammed earth wall structure as well as construction method thereof

A technology for constructing columns and walls, applied in building structures, walls, building components, etc., can solve the problems of insignificant seismic performance and durability of rammed earth walls, tree felling, ecological environment, damage, etc., and improve the anti-collision ability. , good restraint effect, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

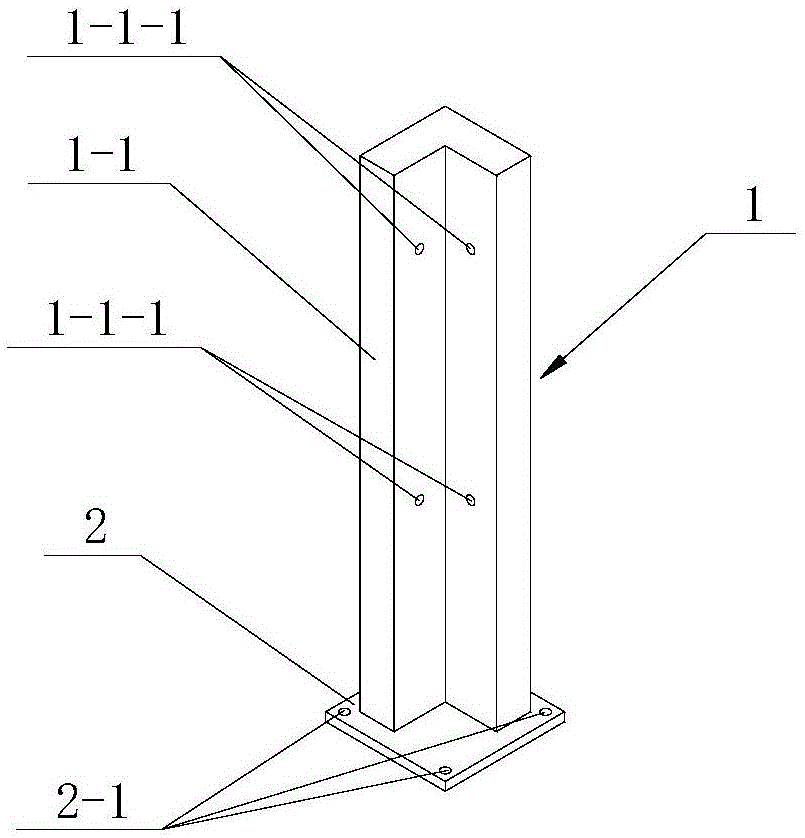

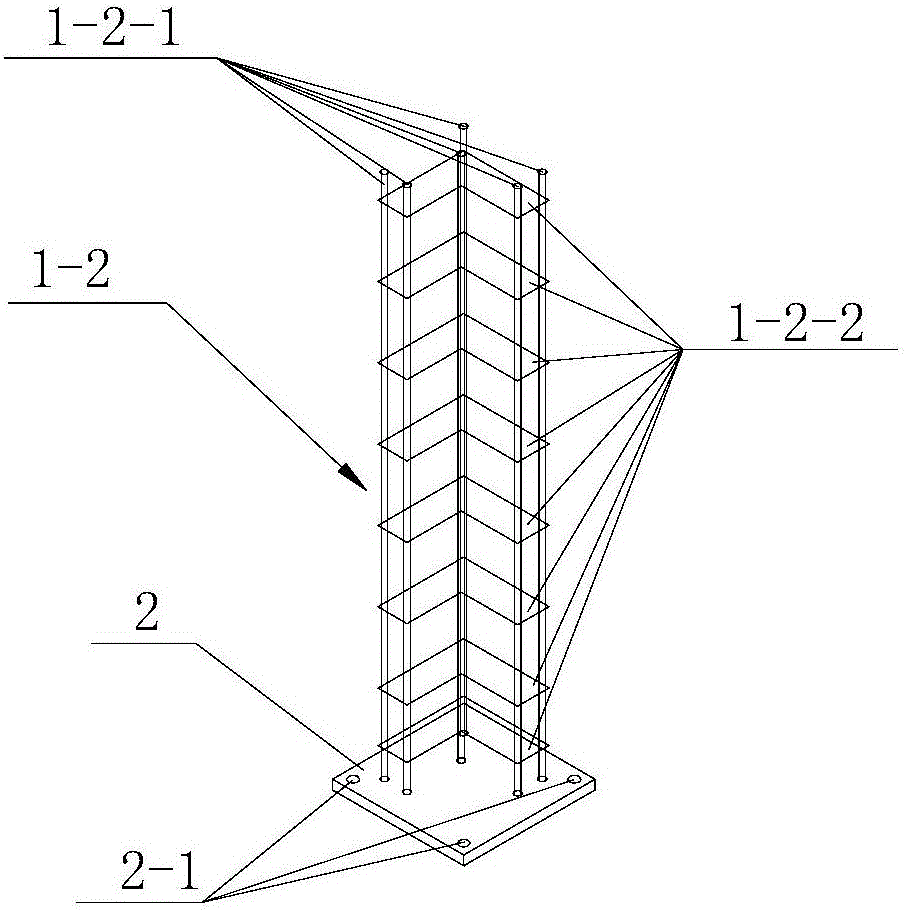

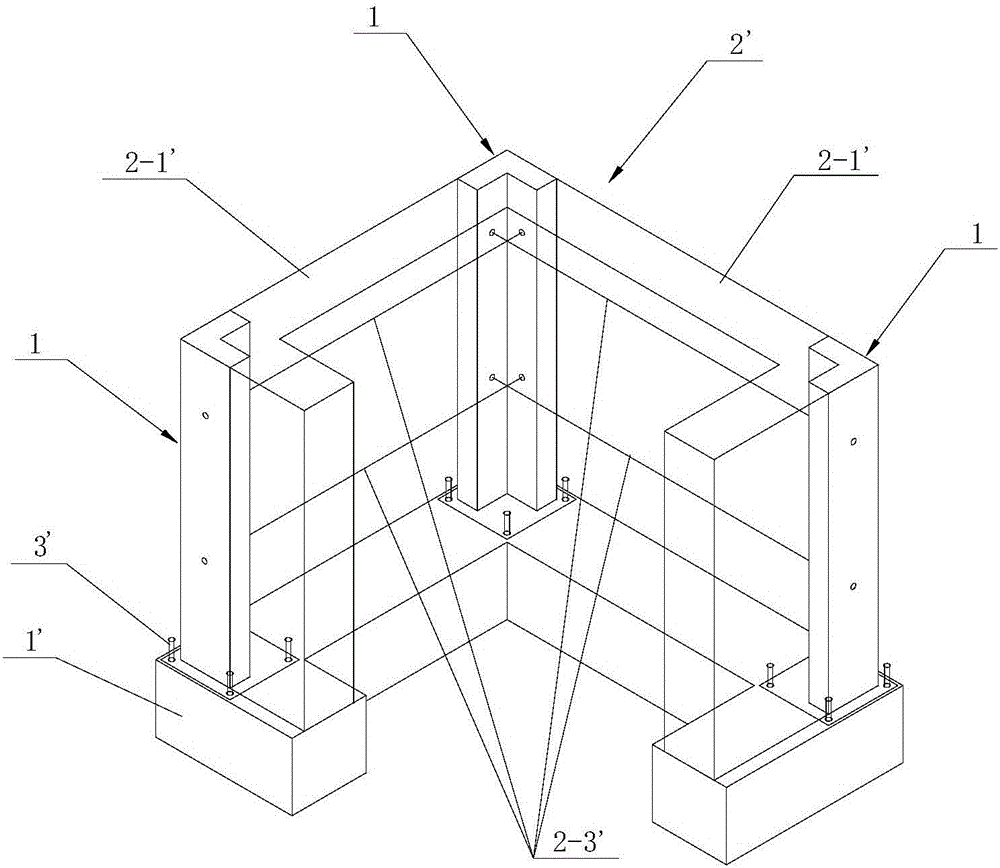

[0023] For prefabricated construction columns at external corners of walls, see Figure 1-2 , the prefabricated structural column is a prefabricated reinforced concrete structure, which includes an L-shaped column part 1 and an end plate part 2 arranged at the lower end of the L-shaped column part. 1-2 structure, a plurality of tie ring installation holes 1-1-1 arranged up and down at intervals are arranged on the two sides of the L-shaped cylinder part. The built-in reinforcing bar skeleton is composed of six main reinforcing bars 1-2-1 arranged upright and multi-layer transverse stirrups 1-2-2 fixed on the six main reinforcing bars along the up and down direction. Specifically, the transverse stirrups are composed of six sections The steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com