Vertical prestress rammed earth wall and construction method thereof

A technology of vertical prestressing and rammed earth walls, applied in the direction of walls, structural elements, building components, etc., can solve the problems of insignificant shear resistance and small occlusal force, so as to improve the shear bearing capacity and enhance the bonding force , Enhance the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

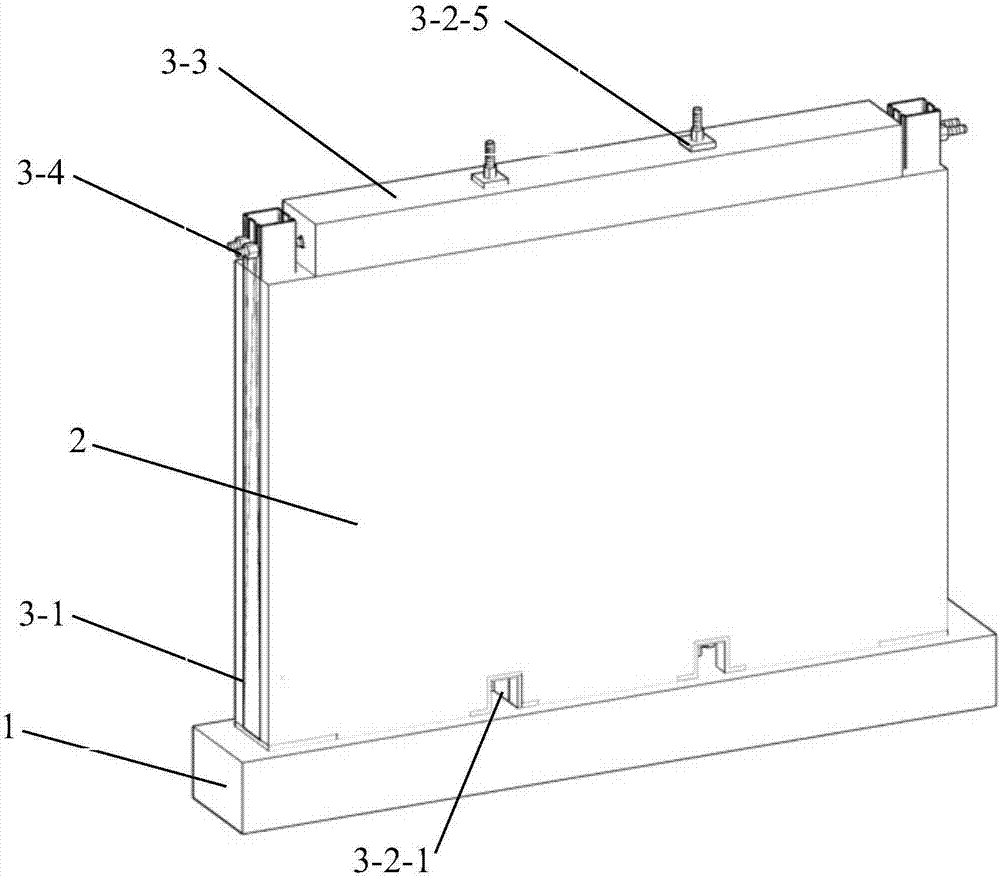

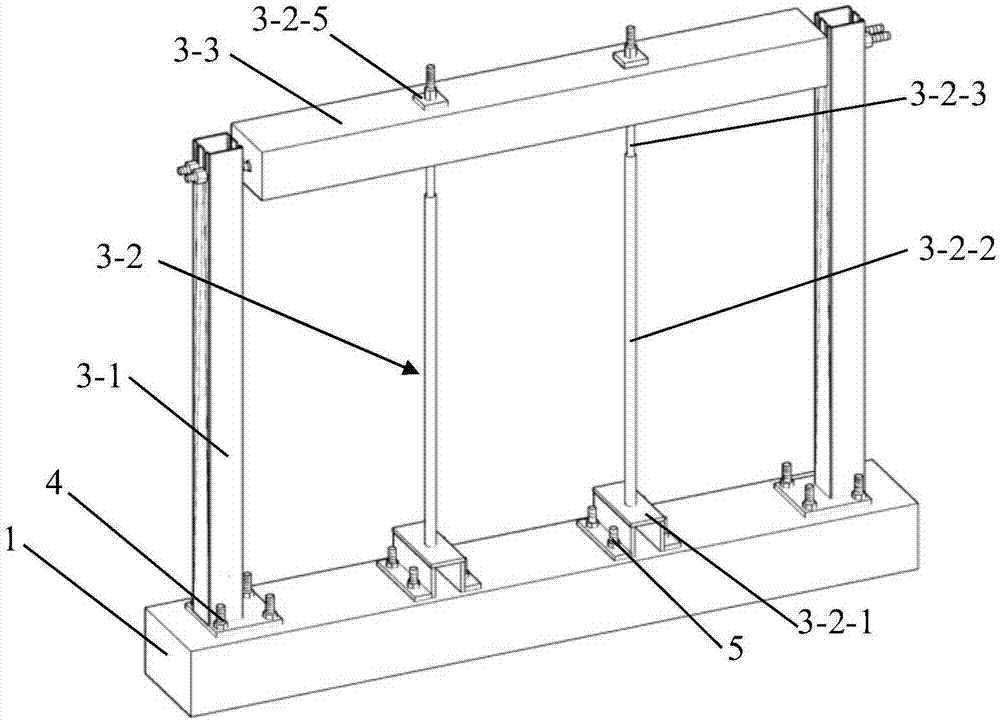

[0040] See Figure 1-8 , The vertical prestressed rammed earth wall, the invention points are: including the wall foundation 1, the rammed earth main body 2 and the vertical prestressing structure 3.

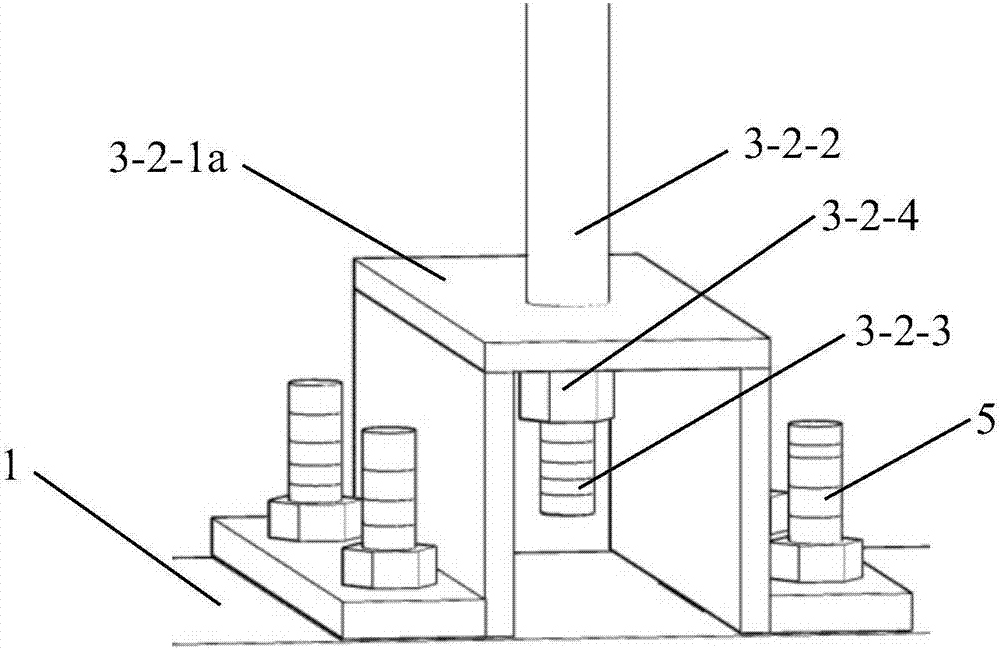

[0041] A plurality of sets of pre-embedded bolts protruding upward are arranged on the wall foundation from one end to the other end. The two sets of pre-embedded bolts at the two ends are embedded bolts 4 for structural column connection, and the remaining embedded bolts are connected by pre-stressed parts. Use embedded bolts 5.

[0042] The vertical prestressing structure includes two structural columns 3-1, multiple sets of prestressing members 3-2, and a top beam 3-3. The specific structure and connection of the three components of the vertical prestressing structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com