Arch fixing rack for highway/railway tunnel and manufacturing method of arch fixing rack

A manufacturing method and railway technology, applied in excavation, construction, infrastructure engineering and other directions, can solve the problems of low grade of rubble rubble, poor labor and time-consuming effect, low on-site operation efficiency, etc., to achieve simple assembly and avoid soil. The effect of body erosion and shortening of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

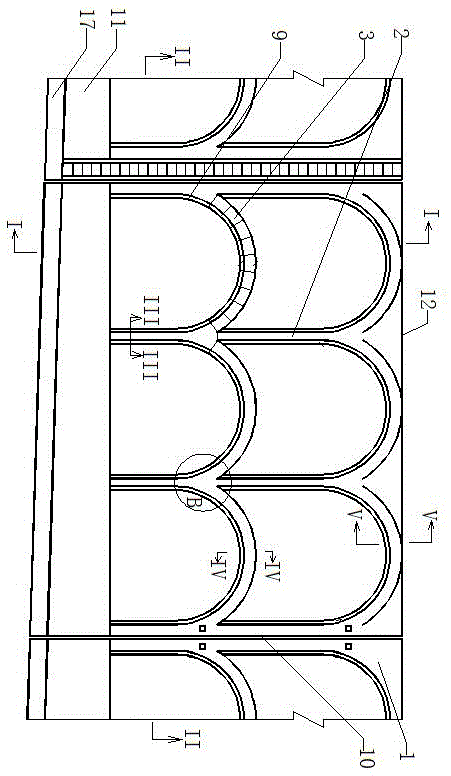

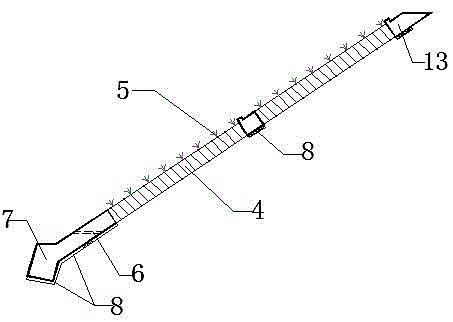

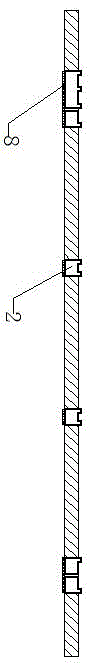

[0037] Such as Figure 1 to Figure 8 The shown arch frame for highway and railway tunnels includes a main body 1; the main body 1 includes a rib column 2 and an arch ring 3; the arch ring 3 is arranged on both sides of the rib column 2; the rib column 2 and the Earthwork 4 is tamped and filled between the arch rings 3; shrubs 5 are planted on the earthwork 4; the bottom of the main body 1 has a Z-shaped hollow structure, and a drainage groove 6 is arranged inside it, adopting a Z-shaped hollow structure, so that The foot protector 7 is firmly occluded, which also makes the surface rainwater not easy to infiltrate. Even if there is little infiltration, it will be discharged from the hollow tube, avoiding the erosion of the soil under the solid frame; the rib column 2 and the bottom of the arch ring 3 are respectively A crushed stone cushion 8 is provided; the junction B of the rib column 2 and the arch ring 3 has a staggered tooth structure, which is easy to assemble, requires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com