Novel rammed earth wall and forming method thereof

A rammed earth wall, a new type of technology, applied in the field of new rammed earth walls and their molding, can solve the problems of poor impermeability, large construction gaps, wall foot collapse, etc., achieve beautiful applicability, improve construction efficiency, and improve The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

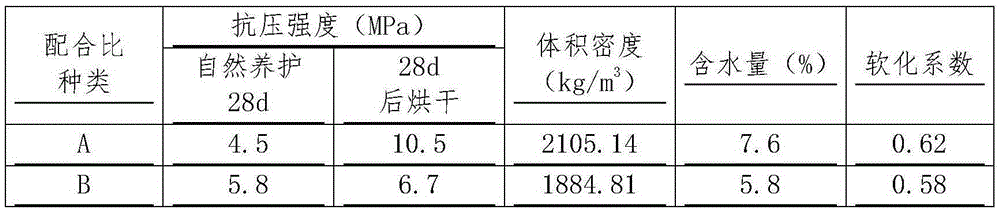

Embodiment 1

[0037] A new type of rammed earth wall, including silt or clay, cement with a specification of P C32.5, lime, sand, polyester fiber and soil stabilizer, wherein the weight distribution ratio is as follows:

[0038] Silt or clay 65.10 parts cement 18.15 parts sand 11.60 parts

[0039] Lime 4.70 parts Soil stabilizer 0.03 parts Polyester fiber 0.42 parts.

Embodiment 2

[0041] A new type of rammed earth wall, comprising silt or clay, cement with a specification of P C32.5, lime, sand and polyester fiber, the weight ratio of the rammed earth wall is as follows:

[0042] Silt or clay 73.10 parts cement 8.21 parts sand 13.05 parts

[0043] 5.22 parts of white ash and 0.42 parts of polyester fiber.

Embodiment 3

[0045] A new type of rammed earth wall, including silt or clay, cement with a specification of P C32.5, lime, sand, polyester fiber and soil stabilizer, wherein the weight distribution ratio is as follows:

[0046] 60 parts of silt or clay 20 parts of cement 15 parts of sand

[0047] Lime 6 parts Soil stabilizer 0.05 parts

[0048] 0.50 parts of polyester fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com